Method for extruding a mat of pressed material

A technology for pressing materials and pressing plates, which is applied in applications, presses, household appliances, etc., and can solve the problems of wood-based panels such as decreased strength, rubber bridge fracture, and pressure fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

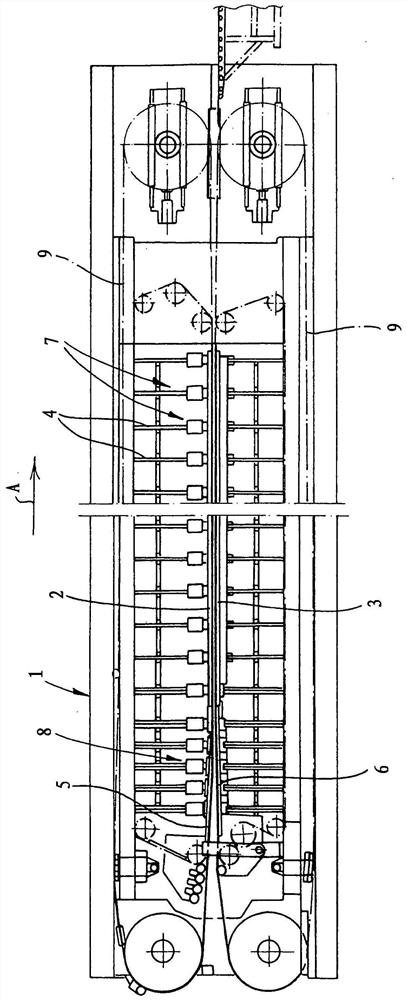

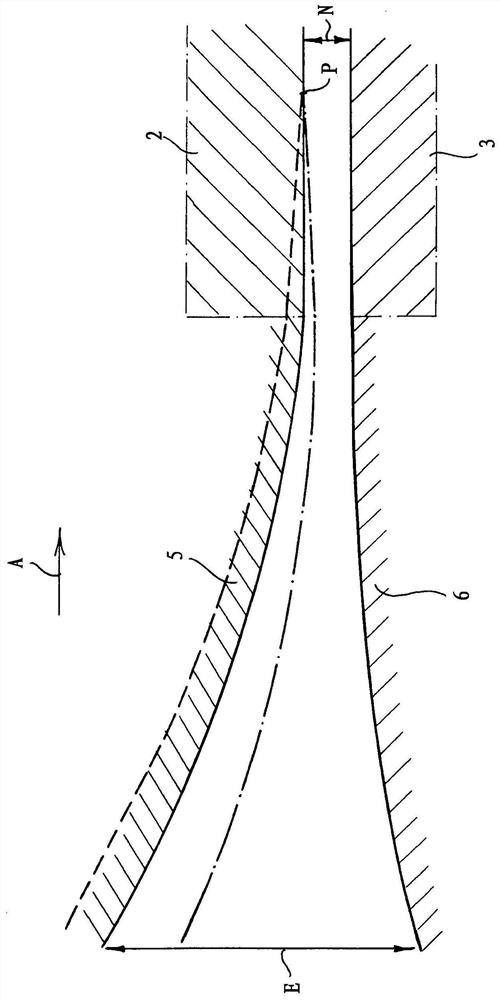

[0028] figure 1 A continuously operating press for the production of wood-based panels, in particular fibreboard, is shown. In such a continuous press, a mat of pressed material made of glued wood particles, such as glued wood fibers, having an input thickness (E) entering the press in the working direction A is continuously extruded into a wood-based panel or Faux slats. The press has a press frame 1 . In this embodiment, an upper main platen 2 is provided in the upper part of the press and a lower main platen 3 is provided in the lower part of the press. The main pressure plates 2 , 3 are heatable and are therefore designed as heating plates with integrated heating channels. The press frame 1 comprises a plurality of press frames 4 arranged in a row along the longitudinal direction of the press. Furthermore, the press has an upper inlet platen 5 arranged upstream of the upper main platen 2 on the inlet side and a lower inlet platen 6 arranged upstream of the lower main p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com