A zeolite-supported ag-doped bifeo 3 /bi 2 fe 4 o 9 Composite materials and their preparation methods and applications

A composite material and zeolite technology, applied in chemical instruments and methods, water/sludge/sewage treatment, chemical/physical processes, etc., can solve the problem of single semiconductor photocatalyst carrier, weak visible light catalytic performance, poor recyclability, etc. problem, to achieve good visible light catalytic performance, inhibit recombination rate, and avoid the use of strong alkali

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

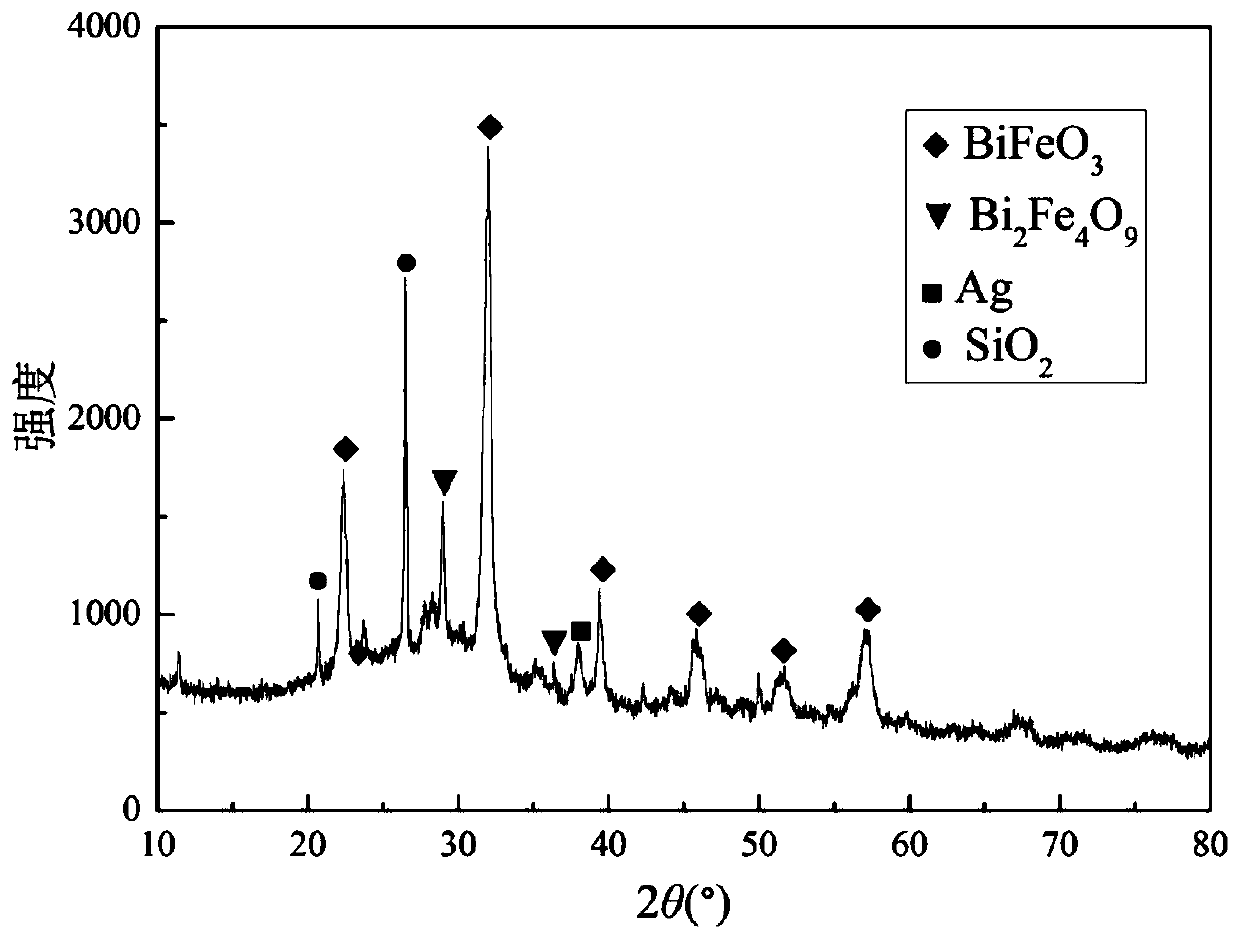

Image

Examples

Embodiment 1

[0025] (1) Weigh 0.5g natural stilbite, 0.404g Fe(NO 3 ) 3 9H 2 O and 0.04gAgNO 3 Stir and disperse in 10g deionized water to obtain mixed solution A;

[0026] (2) Weigh 0.4851g Bi(NO 3 ) 3 ·5H 2 O was stirred and dissolved in 3.12g ethylene glycol to obtain mixed solution B;

[0027] (3) 1 g of urea was dissolved in 6 g of deionized water to obtain a mixed solution C;

[0028](4) Slowly add the mixed solution A obtained in step (1) to the mixed solution B obtained in step (2), stir for 1 min to obtain the mixed solution D, then slowly add the mixed solution C obtained in step (3) to the mixed solution In D, stir for 1 min to obtain mixed solution E;

[0029] (5) Put the mixture E obtained in step (4) in a water bath at 95°C to form a sol, then place it in an oven at 130°C to form a gel, then place it in a tube furnace at 580°C, and calcine it under a nitrogen atmosphere for 3 hours. Obtaining zeolite-supported Ag-doped BiFeO 3 / Bi 2 Fe 4 o 9 composite material. ...

Embodiment 2

[0031] (1) Weigh 0.75g natural clinoptilolite, 0.303g Fe(NO 3 ) 3 9H 2 O and 0.015gAgNO 3 Stir and disperse in 9g deionized water to obtain mixed solution A;

[0032] (2) Weigh 0.3638g Bi(NO 3 ) 3 ·5H 2 O was stirred and dissolved in 1.95g ethylene glycol to obtain mixed solution B;

[0033] (3) 1.2g of urea was dissolved in 12g of deionized water to obtain mixed solution C;

[0034] (4) Slowly add the mixed solution A obtained in step (1) to the mixed solution B obtained in step (2), stir for 5 minutes to obtain the mixed solution D, and then slowly add the mixed solution C obtained in step (3) to the mixed solution In D, stir for 5 minutes to obtain mixed solution E;

[0035] (5) Put the mixed liquid E obtained in step (4) in a water bath at 98°C to form a sol, then place it in an oven at 120°C to form a gel, then place it in a tube furnace at 560°C, and calcine it under a nitrogen atmosphere for 2 hours. Obtaining zeolite-supported Ag-doped BiFeO 3 / Bi 2 Fe 4 o ...

Embodiment 3

[0037] (1) Weigh 1.72g natural mordenite, 1.0423g Fe(NO 3 ) 3 9H 2 O and 0.086gAgNO 3 Stir and disperse in 23g deionized water to obtain mixed solution A;

[0038] (2) Weigh 1.2516g Bi(NO 3 ) 3 ·5H 2 O was stirred and dissolved in 6.88g ethylene glycol to obtain mixed solution B;

[0039] (3) 3.1g of urea was dissolved in 19g of deionized water to obtain mixed solution C;

[0040] (4) Slowly add the mixed solution A obtained in step (1) to the mixed solution B obtained in step (2), stir for 3 minutes to obtain the mixed solution D, then slowly add the mixed solution C obtained in step (3) to the mixed solution In D, stir for 3 minutes to obtain mixed solution E;

[0041] (5) Put the mixture E obtained in step (4) in a water bath at 98°C to form a sol, then place it in an oven at 125°C to form a gel, then place it in a tube furnace at 570°C, and calcine it under a nitrogen atmosphere for 3 hours. Obtaining zeolite-supported Ag-doped BiFeO 3 / Bi 2 Fe 4 o 9 composite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com