Rotary type welding device

A welding device and rotary technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problem of unstable placement of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

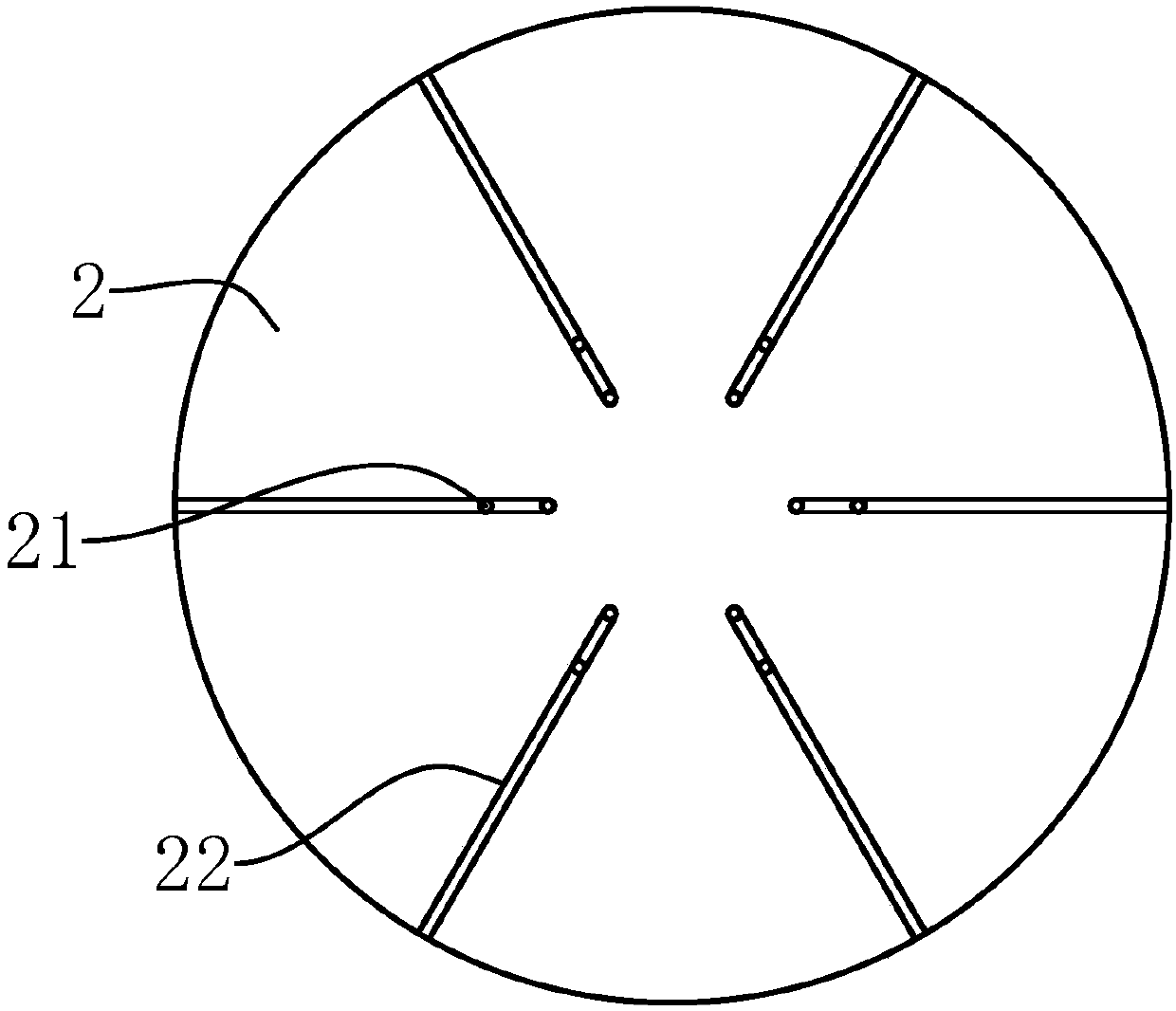

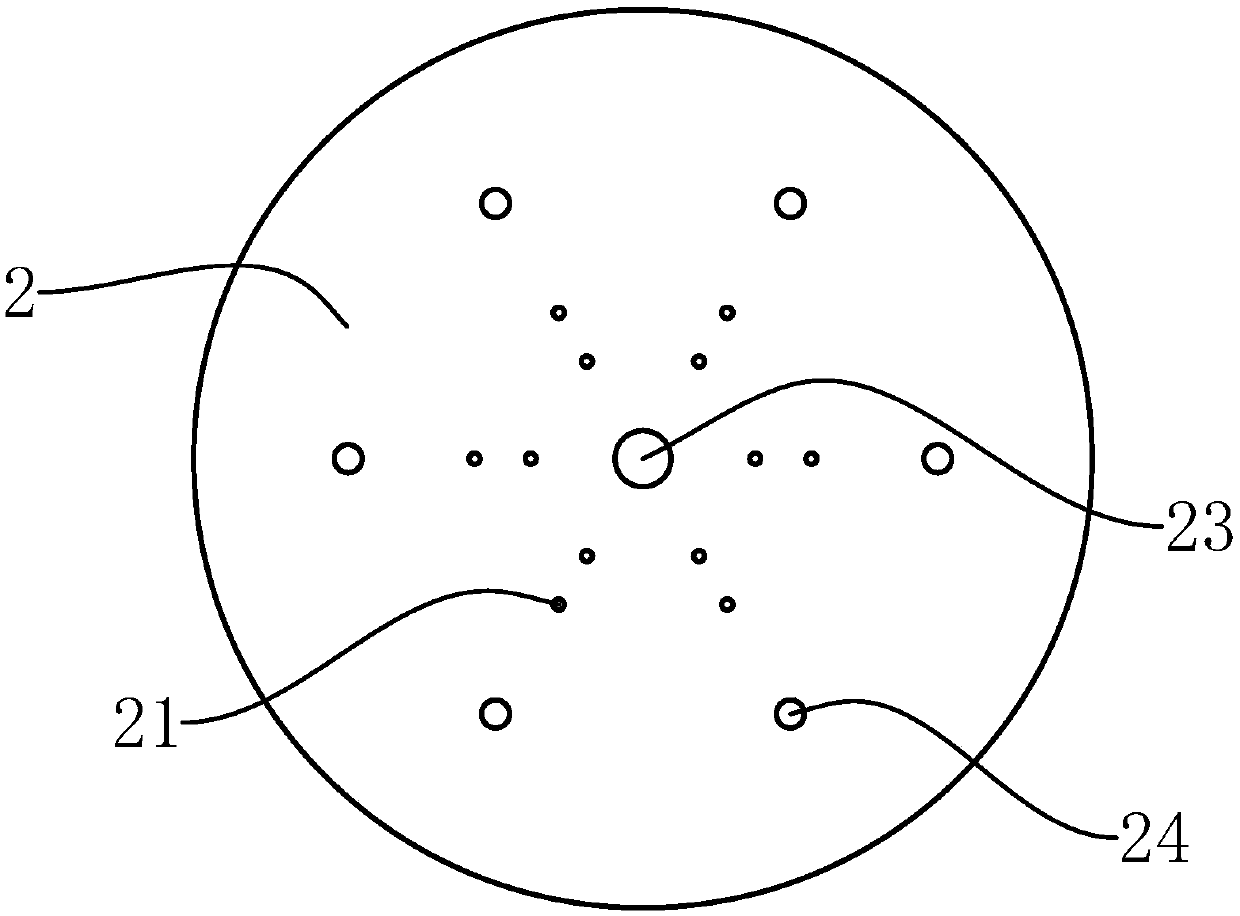

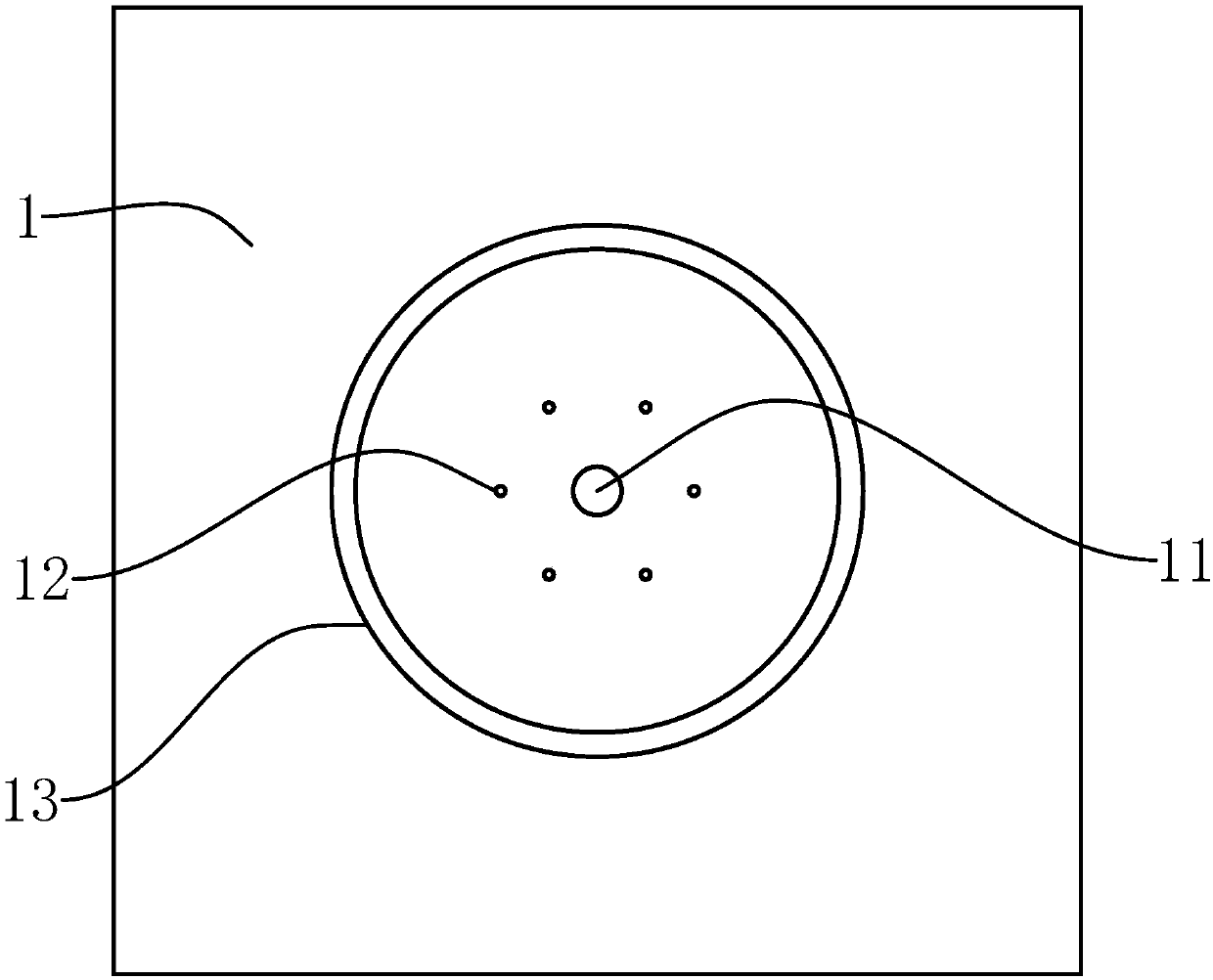

[0021] Such as Figure 1-3 As shown, the present invention has a rotary welding device, including a workbench 1 and a circular platen 2 arranged above the workbench 1. The top surface of the platen 2 is provided with several positioning holes 21 and positioning grooves 22. The top surface of the workbench 1 is There is a pin groove 11 on the surface, and the center position of the bottom surface of the table 2 is rotatably connected with a rotating shaft 23. The rotating shaft 23 is detachably inserted into the pin groove 11. There are a number of balls 24 on the bottom of the table 2, and the bottom of the ball 24 is against the top of the workbench 1. face.

[0022] Further, a number of fixing holes 12 are provided on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com