a sawing device

The technology of sawing wood and disc cutter is applied in the field of wood processing, which can solve the problems of potential safety hazards, difficulty in controlling the feeding speed, being involved in the sawing knife, etc., and achieve the effects of preventing sawdust from splashing, having a simple structure and being easy to implement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

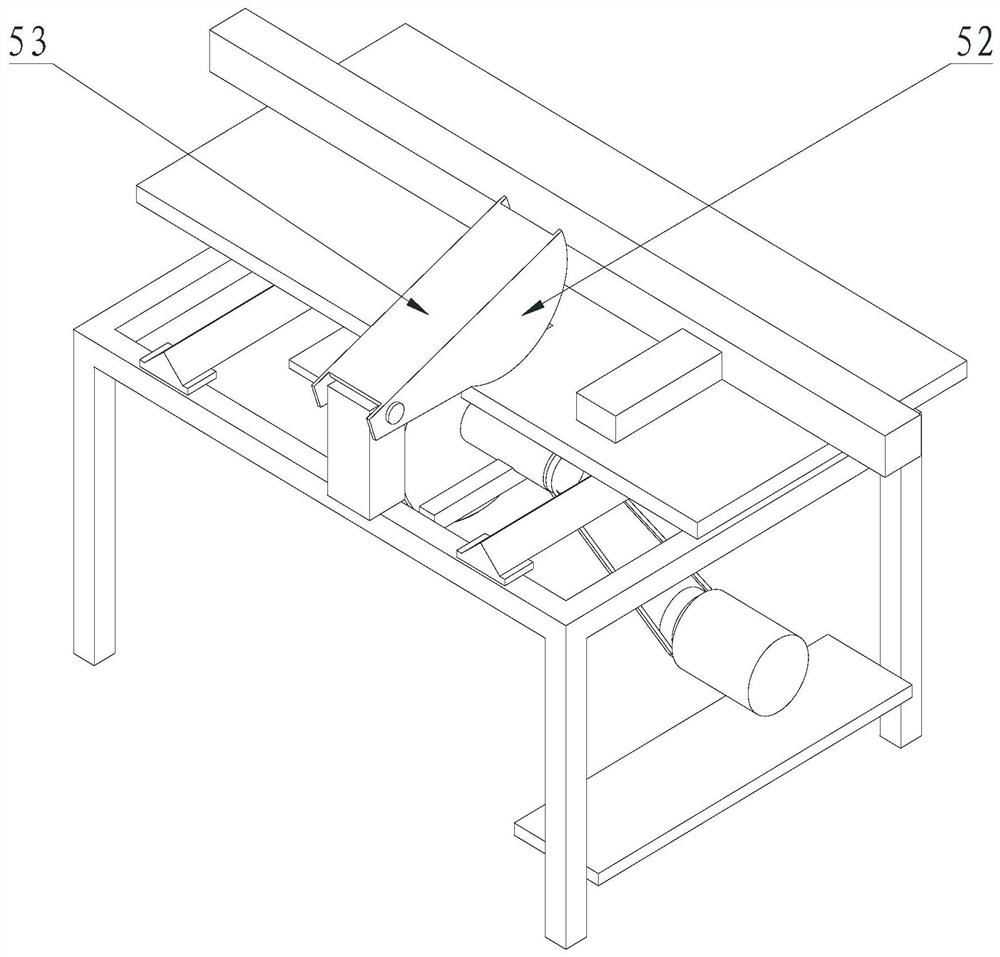

[0016] The most critical idea of the present invention is that a boss on the plane of the left end plate or the right end plate is provided on the support plate to gradually lift up the protective cover during the pushing process of the shelf plate without affecting the sawing process. Operation.

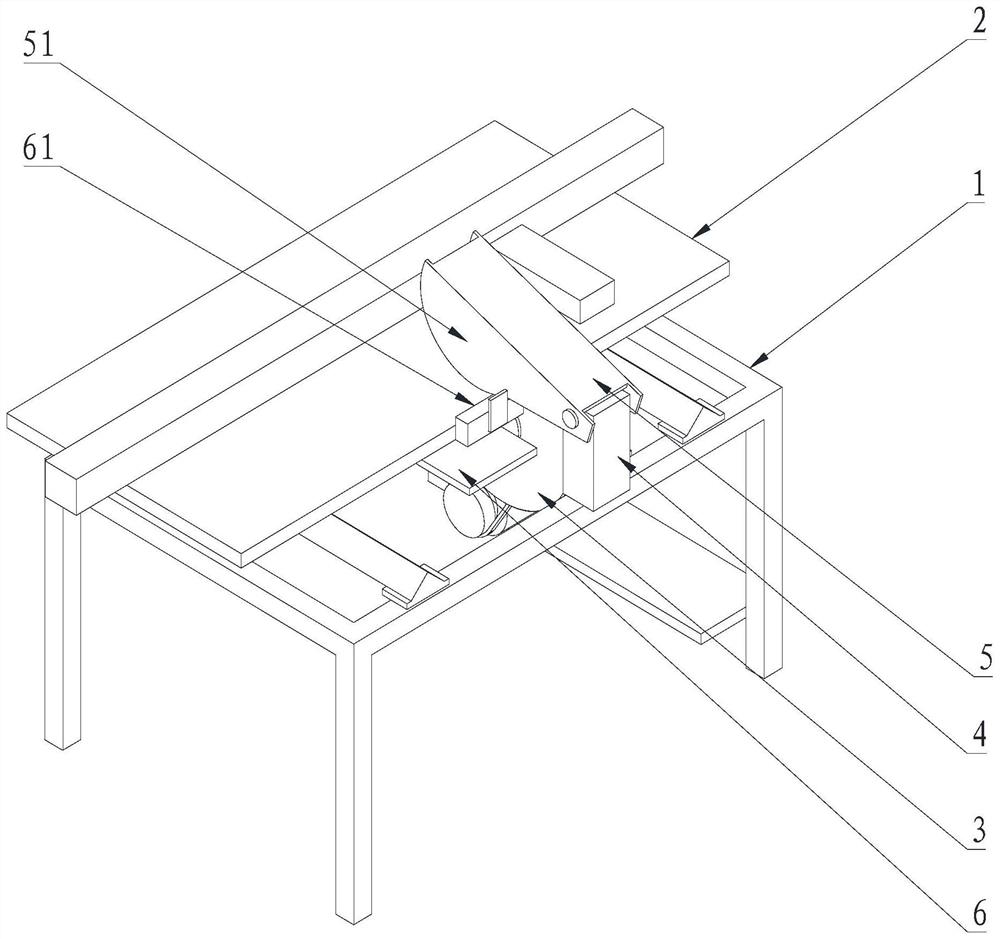

[0017] Please refer to Figure 1 to Figure 2 , a sawing device, comprising a machine platform 1, a frame plate 2 is provided on one side of the machine platform 1, a disc cutter 3 is provided on the other side of the machine platform 1, and the machine platform 1 is located at the The side of the disc cutter 3 away from the feeding direction is provided with a column 4, and the column 4 is provided with a protective cover 5 covering the upper end of the disc cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com