Cold-rolled steel strip slitting device

A cold-rolled steel strip and slitting technology, which is used in household refrigeration equipment, metal rolling, metal rolling, etc., can solve the problems of tool cracks, difficult tool cooling treatment, etc., and achieve the effect of prolonging the service life and preventing damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

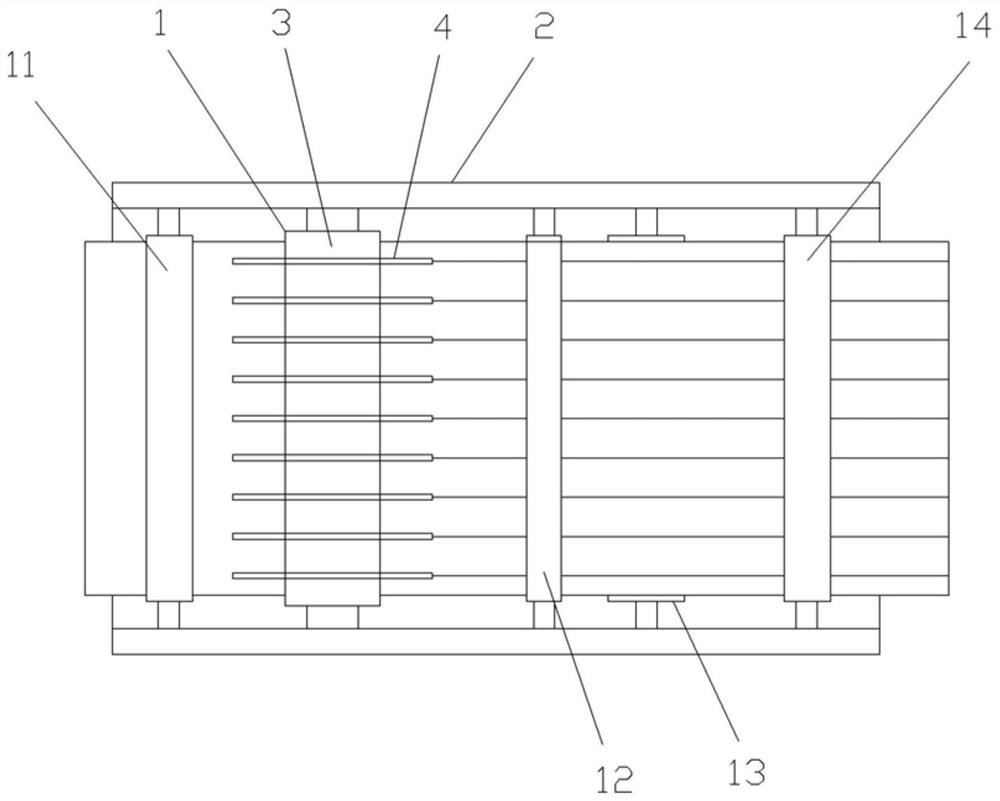

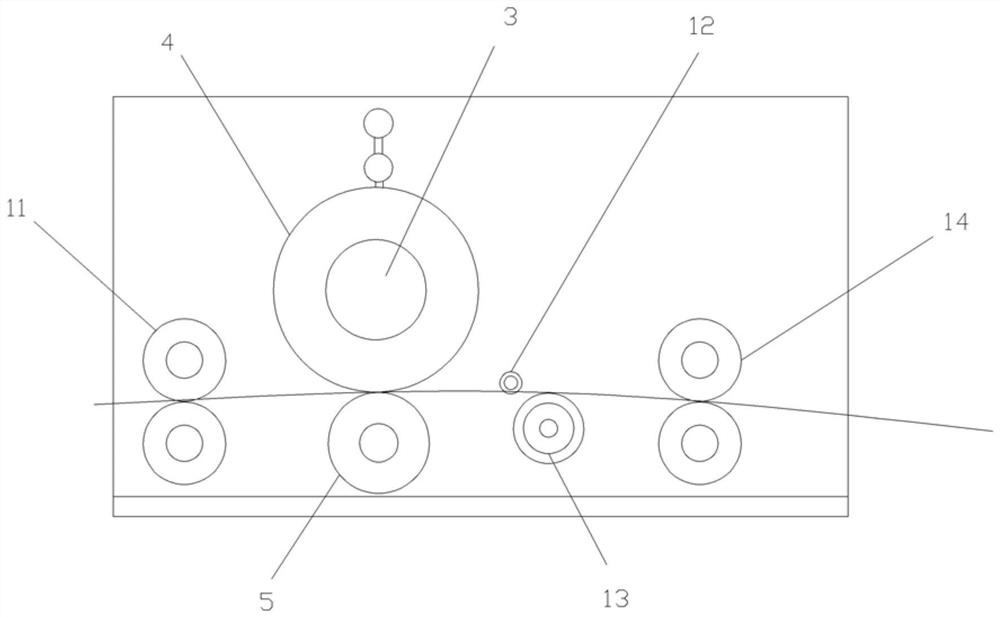

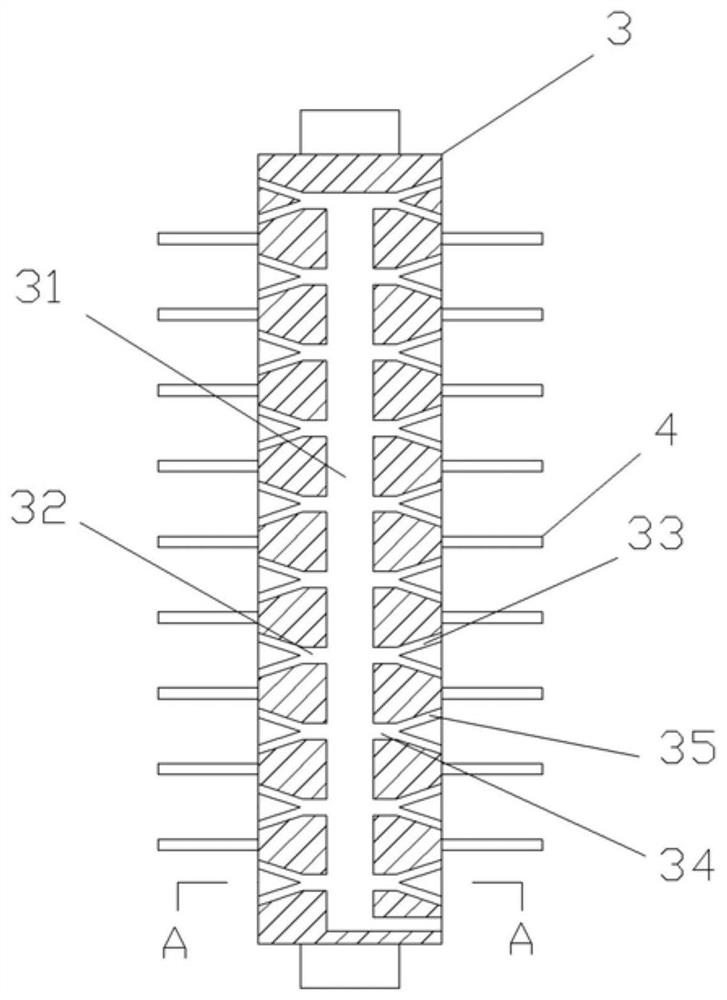

[0018] refer to Figure 1 to Figure 6 , a cold-rolled strip slitting device of the present invention comprises a slitting device main body 1, a frame 2 is arranged on the slitting device main body 1, a cutting roller 3 is installed on the frame 2, and the cutting roller 3 is evenly equipped with a cutting blade 4, the bottom of the cutting roller 3 is provided with a siping roller 5, the front side of the cutting roller 3 is provided with a first limit roller 11, and the rear side of the cutting roller 3 is provided with Pressure roller 12, the below of described pressure roller 12 is provided with guide roller 13, and the rear side of described pressure roller 12 is provided with second limiting roller 14, and described cutting roller 3 is provided with air inlet channel 31, and described cutting The surface of the roller 3 is provided with several groups of air outlet passages 32, each group of air outlet passages 32 are spaced apart from the cutting blade 4, and each group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com