Novel manufacturing process for aluminum alloy specially-shaped doors and windows

A production process and aluminum alloy technology, which is applied in the field of production process of new aluminum alloy special-shaped doors and windows, can solve the problems of inaccuracy, deviation of special-shaped aluminum alloy doors and windows, affecting work efficiency, etc., to reduce the area, improve the cutting speed, and facilitate use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

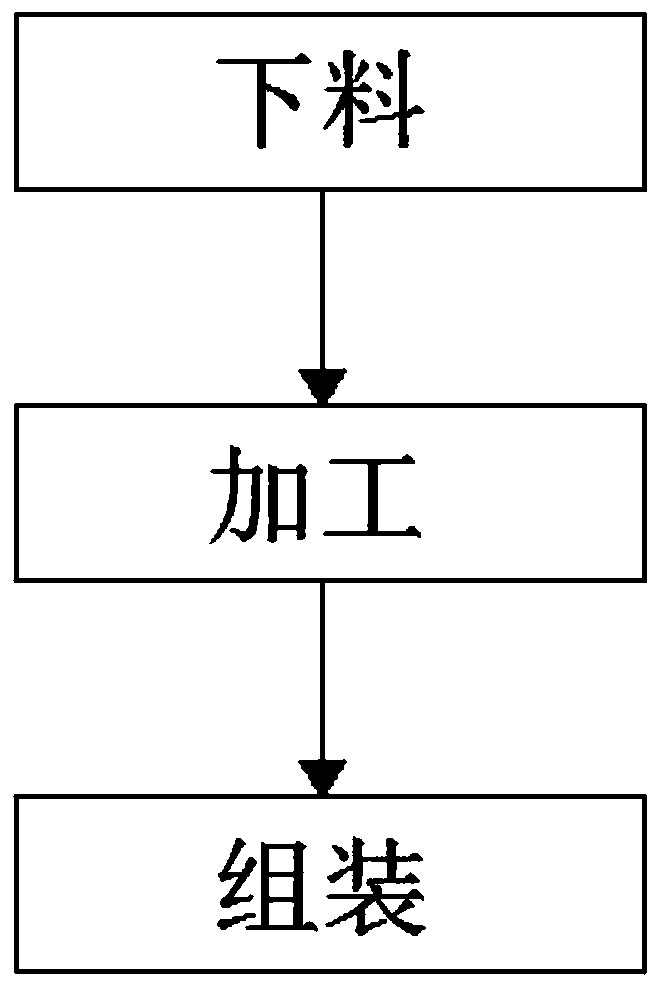

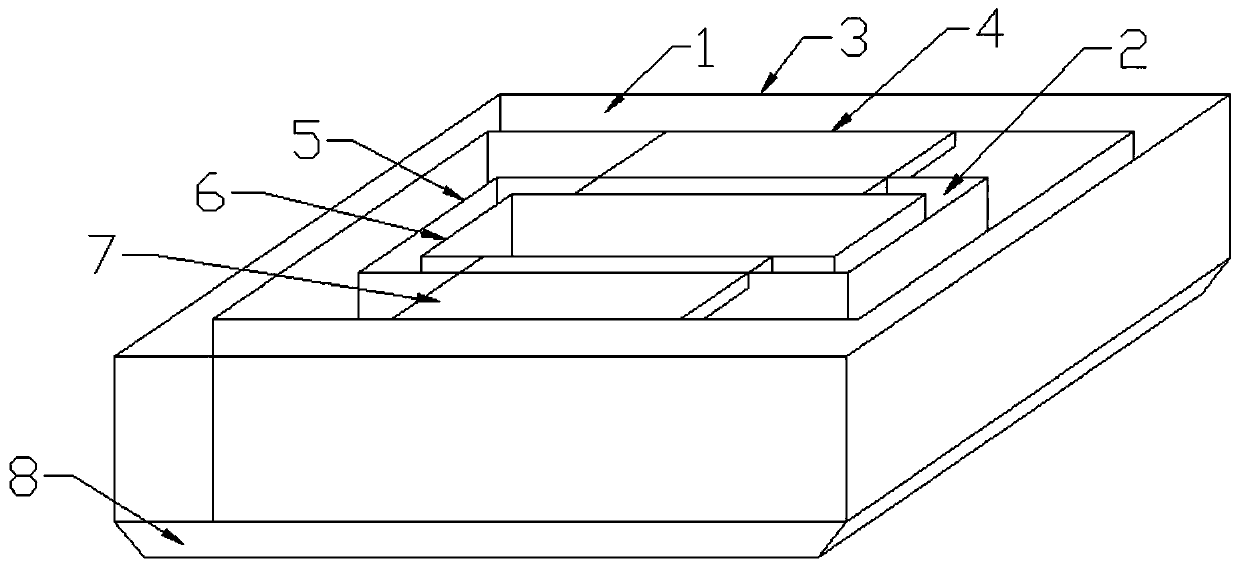

[0027] Such as Figure 1-2 As shown, the invention discloses a manufacturing process of a novel aluminum alloy special-shaped door and window, and the specific steps are as follows:

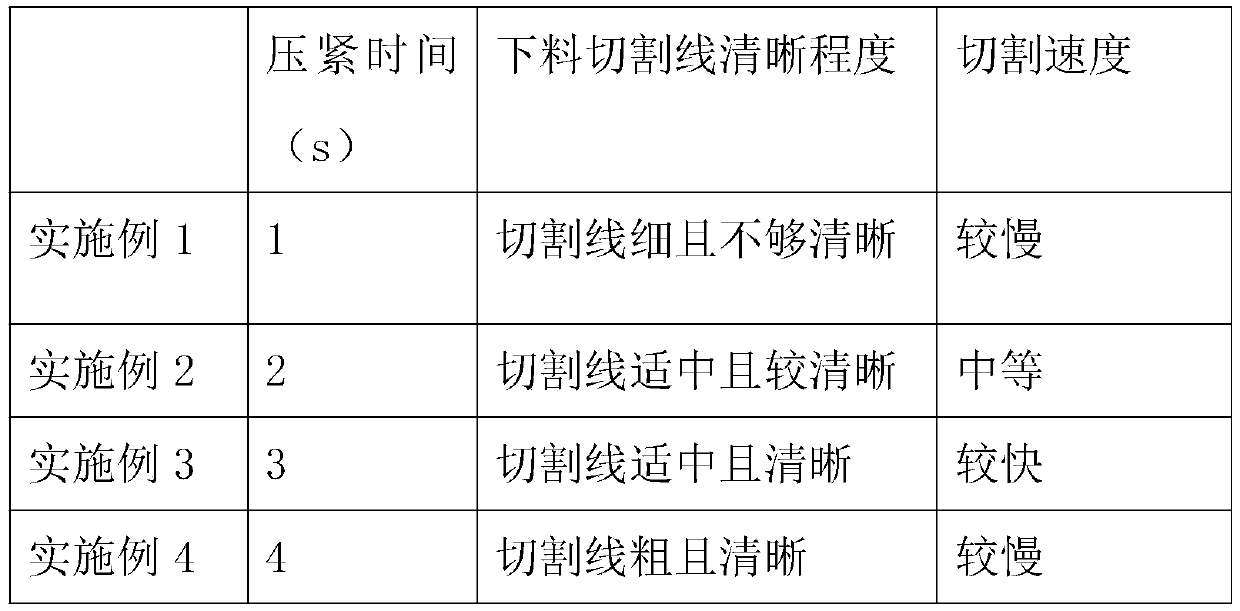

[0028] (1) For blanking, first cut out the blanks of special-shaped doors and windows on the aluminum alloy plate, then engrave or die-cast the blanks through an engraving machine or die-casting machine, then perform coloring on the blanks, and then make a blanking mold , and put wipeable paint into the blank, select a suitable position on the blank, press the blank on the blank for 1 second, so that the pigment forms a blanking cutting line on the blank, and finally along the blanking line Cut out profiles of special-shaped doors and windows;

[0029] (2) For processing, first determine the number and position of the drainage holes on the profile according to the needs, and then mill the drainage holes;

[0030] (3) Assemble, clean the profile, and then apply an appropriate amount of corner gl...

Embodiment 2

[0038] Such as Figure 1-2 As shown, the invention discloses a manufacturing process of a novel aluminum alloy special-shaped door and window, and the specific steps are as follows:

[0039] (1) For blanking, first cut out the blanks of special-shaped doors and windows on the aluminum alloy plate, then engrave or die-cast the blanks through an engraving machine or die-casting machine, then perform coloring on the blanks, and then make a blanking mold , and put wipeable paint into the blank, select a suitable position on the blank, press the blank on the blank for 2 seconds, so that the pigment forms a blanking cutting line on the blank, and finally along the blanking line Cut out profiles of special-shaped doors and windows;

[0040] (2) For processing, first determine the number and position of the drainage holes on the profile according to the needs, and then mill the drainage holes;

[0041] (3) Assemble, clean the profile, and then apply an appropriate amount of corner g...

Embodiment 3

[0049] Such as Figure 1-2 As shown, the invention discloses a manufacturing process of a novel aluminum alloy special-shaped door and window, and the specific steps are as follows:

[0050] (1) For blanking, first cut out the blanks of special-shaped doors and windows on the aluminum alloy plate, then engrave or die-cast the blanks through an engraving machine or die-casting machine, then perform coloring on the blanks, and then make a blanking mold , and put wipeable paint into the blank, select a suitable position on the blank, press the blank on the blank for 3 seconds, so that the pigment forms a blanking cutting line on the blank, and finally along the blanking line Cut out profiles of special-shaped doors and windows;

[0051] (2) For processing, first determine the number and position of the drainage holes on the profile according to the needs, and then mill the drainage holes;

[0052] (3) Assemble, clean the profile, and then apply an appropriate amount of corner glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com