Preparation method of insect-resisting agent for wood

An insect repellant and wood technology, applied in wood treatment, impregnation of wood, wood impregnation, etc., can solve the problems of affecting the service life of wood, wood prone to insects, etc., and achieve the effect of preventing wood products from infestation, good air environment, and insecticidal effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

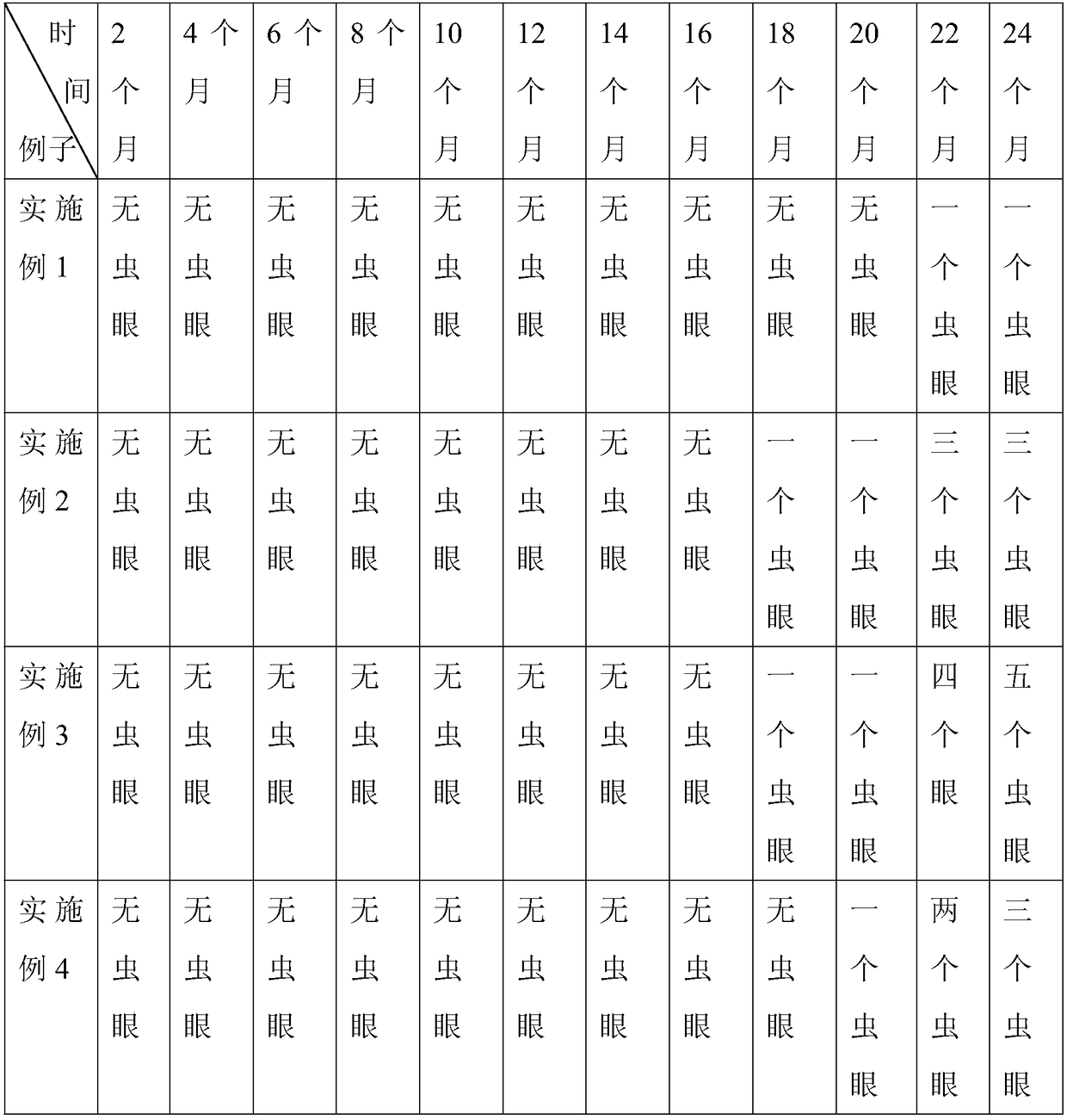

Examples

Embodiment 1

[0021] The preparation method of the insect repellent of this embodiment is:

[0022] Step 1. Weigh 14 parts of neem bark, 12 parts of sandalwood bark, 18 parts of Shanmutong, 37 parts of Bupleurum, and 7 parts of star anise according to the parts by weight;

[0023] Step 2. Put Neem bark, sandalwood bark, Shanmu Tong, star anise and Bupleurum in a wok and fry together. After frying for 22 minutes, turn off the heat, cover the pot, simmer for 3 minutes, then take it out for use;

[0024] Step 3. Put the neem bark, sandalwood bark, mountain wood tongs, star anise and Bupleurum vulgare treated in step 2 in a pulverizer and pulverize to 160 mesh to obtain powder;

[0025] Step 4. Weigh 25 parts by weight of Sumac leaves, 14 parts lavender, 9 parts thyme, 5 parts chili leaves, and 8 parts mint leaves;

[0026] Step 5, drying the coggygria leaves, lavender, thyme, pepper leaves and mint leaves that have passed through step 4, and crushing them;

[0027] Step 6. Put the cocklebur leaves, laven...

Embodiment 2

[0033] The preparation method of the insect repellent of this embodiment is:

[0034] Step 1. Weigh 12 parts of neem bark, 10 parts of sandalwood bark, 16 parts of Shanmutong, 42 parts of Bupleurum, and 8 parts of star anise according to the parts by weight;

[0035] Step 2. Put Neem bark, sandalwood bark, Shanmu Tong, star anise and Bupleurum in a wok and fry together. After frying for 22 minutes, turn off the heat, cover the pot, simmer for 3 minutes, then take it out for use;

[0036] Step 3. Put the neem bark, sandalwood bark, mountain wood tongs, star anise and bupleurum that have been processed in step 2 in a pulverizer and pulverize to 160 mesh to obtain powder;

[0037] Step 4. Weigh 22 parts of Sumac leaves, 16 parts of lavender, 12 parts of thyme, 6 parts of pepper leaves, and 11 parts of mint leaves according to the parts by weight;

[0038] Step 5, drying the coggygria leaves, lavender, thyme, pepper leaves and mint leaves that have passed through step 4, and crushing them; ...

Embodiment 3

[0045] The preparation method of the insect repellent in this embodiment is:

[0046] Step 1. Weigh 16 parts of neem bark, 15 parts of sandalwood bark, 18 parts of Shanmutong, 37 parts of Bupleurum, and 6 parts of star anise according to the parts by weight;

[0047] Step 2. Put Neem bark, sandalwood bark, Shanmu Tong, star anise and Bupleurum in a wok and fry together. After frying for 15 minutes, turn off the heat, cover the pot, simmer for 2 minutes, then take it out for use;

[0048] Step 3: Put the neem bark, sandalwood bark, mountain wood tongs, star anise and Bupleurum chinensis treated in step 2 in a pulverizer, and pulverize to 120 meshes to obtain powder;

[0049] Step 4. Weigh 26 parts of cocklebur leaves, 12 parts of lavender, 8 parts of thyme, 3 parts of pepper leaves, and 5 parts of mint leaves according to the above weight parts;

[0050] Step 5, drying the coggygria leaves, lavender, thyme, pepper leaves and mint leaves that have passed through step 4, and crushing them;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com