Insect-resisting process for woodwork

A wood product and pest control technology, which is applied in manufacturing tools, wood processing appliances, wood treatment, etc., can solve the problems of wood being prone to insects and affecting the service life of wood, achieve a good air environment, prevent wood products from growing insects and kill insects. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

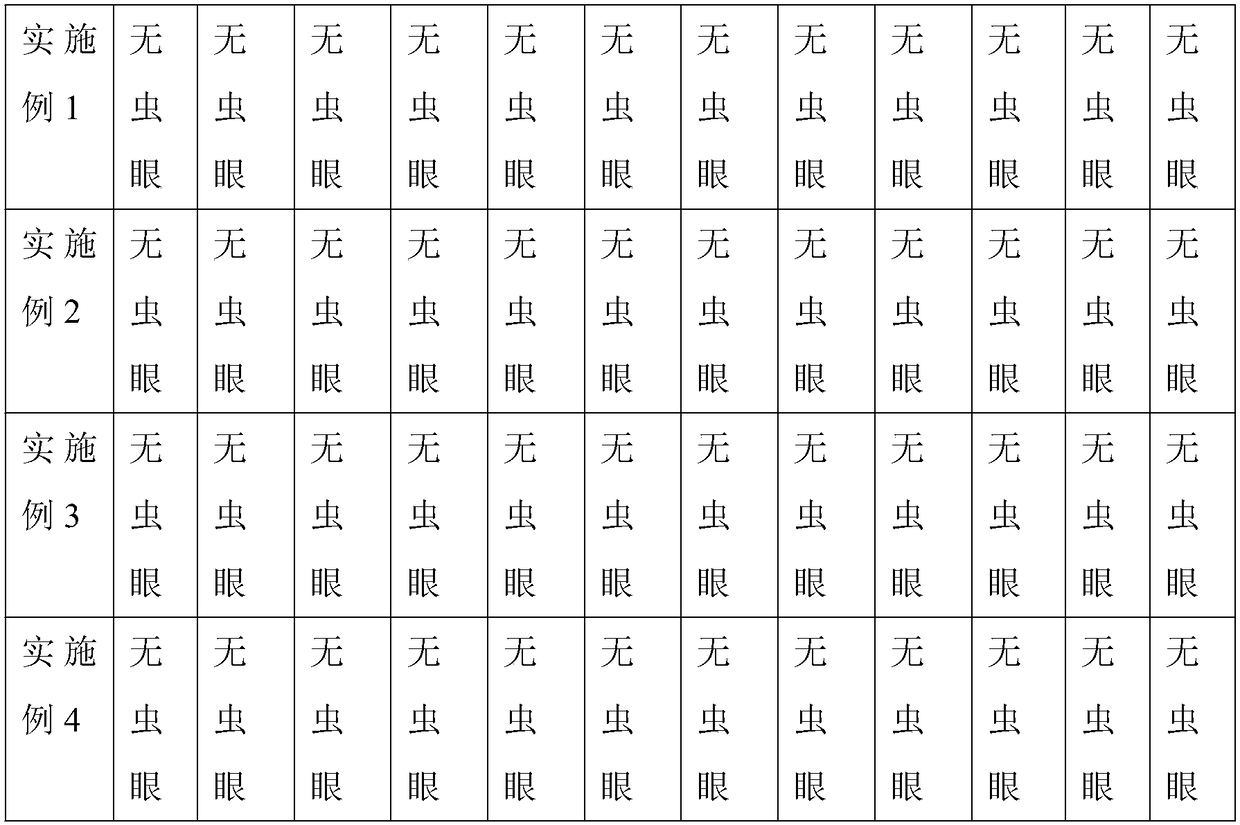

Embodiment 1

[0044] This embodiment provides a kind of insect-proofing process for wood products, which is characterized in that: comprising the following steps:

[0045] Step 1, Drill a hole in the center of the wood, the hole runs through the entire wood, and the hole extends along the axis of the wood;

[0046] Step 2, feed a pipe into the hole, and the pipe is arranged with a plurality of small holes; one end of the pipe is open and the other end is closed;

[0047] Step 3: Pour insect repellant into the tube, and then block the opening of the tube with a rubber stopper. After every 2 hours, remove the rubber stopper, pour insect repellant into the tube, and pour the insect repellant into the tube 6 times. , stop pouring insect repellent liquid;

[0048] Step 4, put the wood treated in step 3 into the airtight room, pass steam into the airtight room, the temperature of the steam is controlled at 112°C, after 2 hours of steaming, stop the steaming, and put the wood in the airtight room...

Embodiment 2

[0056] This embodiment provides a kind of insect-proofing process for wood products, which is characterized in that: comprising the following steps:

[0057] Step 1, Drill a hole in the center of the wood, the hole runs through the entire wood, and the hole extends along the axis of the wood;

[0058] Step 2, feed a pipe into the hole, and the pipe is arranged with a plurality of small holes; one end of the pipe is open and the other end is closed;

[0059] Step 3: Pour insect repellant into the tube, and then block the opening of the tube with a rubber stopper. After every 3 hours, remove the rubber stopper, pour insect repellant into the tube, and pour insect repellent into the tube 7 times. , stop pouring insect repellent liquid;

[0060] Step 4, put the wood treated in step 3 into the airtight room, pass steam into the airtight room, the temperature of the steam is controlled at 120°C, after 2 hours of steaming, stop the steaming, and put the wood in the airtight room Fo...

Embodiment 3

[0090] This embodiment provides a kind of insect-proofing process for wood products, which is characterized in that: comprising the following steps:

[0091] Step 1, Drill a hole in the center of the wood, the hole runs through the entire wood, and the hole extends along the axis of the wood;

[0092] Step 2, feed a pipe into the hole, and the pipe is arranged with a plurality of small holes; one end of the pipe is open and the other end is closed;

[0093] Step 3: Pour insect repellant into the tube, and then block the opening of the tube with a rubber stopper. After every 2 hours, remove the rubber stopper, pour insect repellant into the tube, and fill the tube with insect repellant 5 times. , stop pouring insect repellent liquid;

[0094] Step 4, put the wood treated in step 3 into the airtight room, pass steam into the airtight room, the temperature of the steam is controlled at 110°C, after 2 hours of steaming, stop the steaming, and put the wood in the airtight room Fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com