Steering drive module and corresponding vehicle

A driving module and steering controller technology, which is applied to steering mechanisms, vehicle components, steering mechanisms of front and rear tandem vehicles, etc., can solve the problem of not being able to spare too much weight to carry passengers, insufficient carrying capacity, and narrowing of vehicle body passages and other problems, to achieve the effect of improving the scope of application, facilitating maintenance and replacement, and enhancing bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

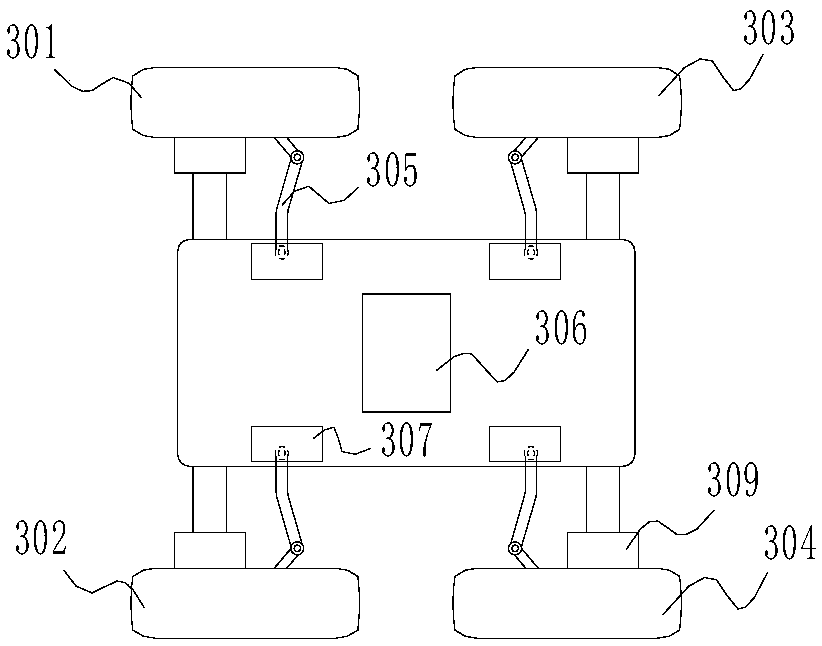

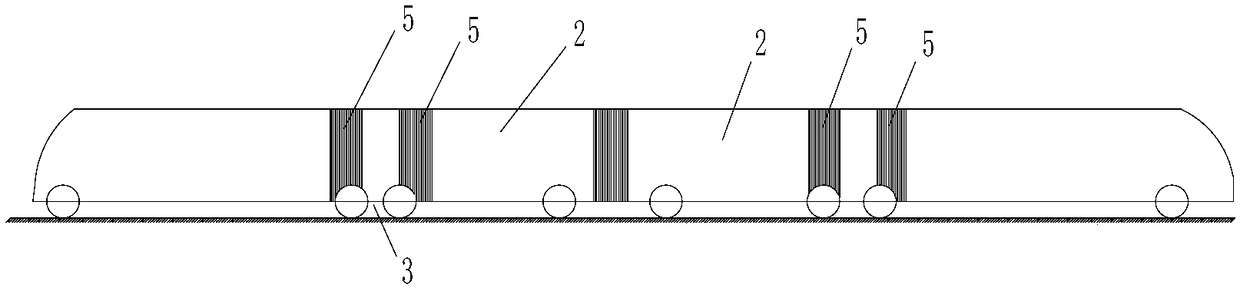

[0038] The first printed track train comprises a body 1 made up of multiple carriages 2, and wheels are arranged below the carriages 2. In this embodiment, a steering drive module 3 is connected between the carriages 2 and the carriages 2. The steering drive module 3 includes Wheel body one 301, wheel body two 302, wheel body three 303 and wheel body four 304, the wheel body one 301 and the wheel body two 302 are located in front of the wheel body three 303 and the wheel body four 304, and Wheel body one 301, wheel body two 302, wheel body three 303 and wheel body four 304 are connected to the base respectively, and a steering system is provided on the base, and the steering system is connected to wheel body one 301, wheel body two 302, The third wheel body 303 and the fourth wheel body 304 are connected by a support.

[0039] The first wheel body 301 and the third wheel body 303 are located on the same side of the vehicle body, and the second wheel body 302 and the fourth whe...

Embodiment 2

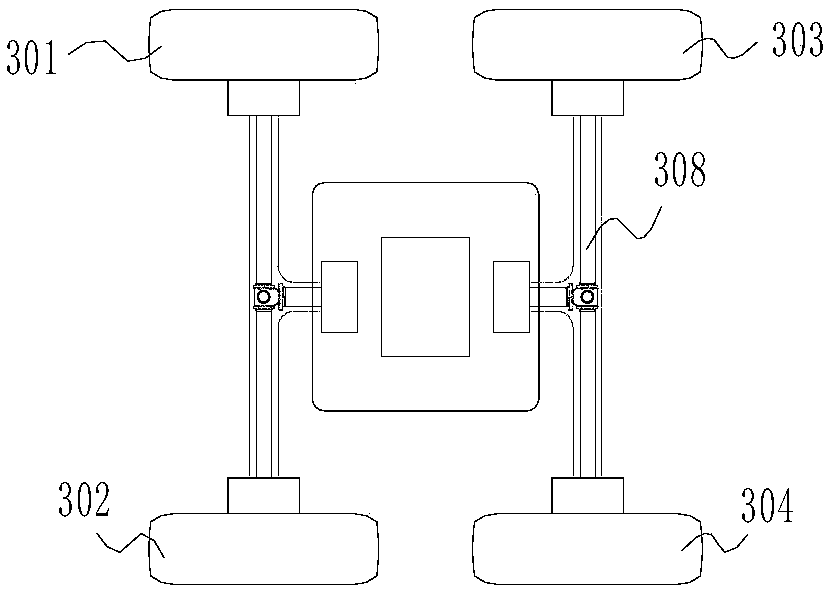

[0053] The second track train is the same as Embodiment 1, and it includes a steering drive module 3. The steering drive module 3 has four wheel bodies, which are respectively wheel body one 301, wheel body two 302, wheel body three 303, wheel body three, and wheel body three. Body 4 304, the positional relationship of each wheel body is the same as that in Embodiment 1, and will not be repeated here.

[0054] Please combine image 3 , wherein, a shaft is connected between the first wheel body 301 and the second wheel body 302, a differential is connected to the middle of the shaft, the differential is connected to a motor, and the third wheel body 303 is connected to the A shaft is also connected between the four wheels 304, and a differential is also connected to the middle of the shaft. The differential is also connected to a motor, and the front and rear differentials and the motor are respectively installed on the base to form a On the whole, the motor and the controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com