Automatic stacking machine

A stacker and automatic walking technology, applied in the field of automation, can solve the problems of no way to drive by itself, no stacker shifting device, no way to automatically shift stacks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

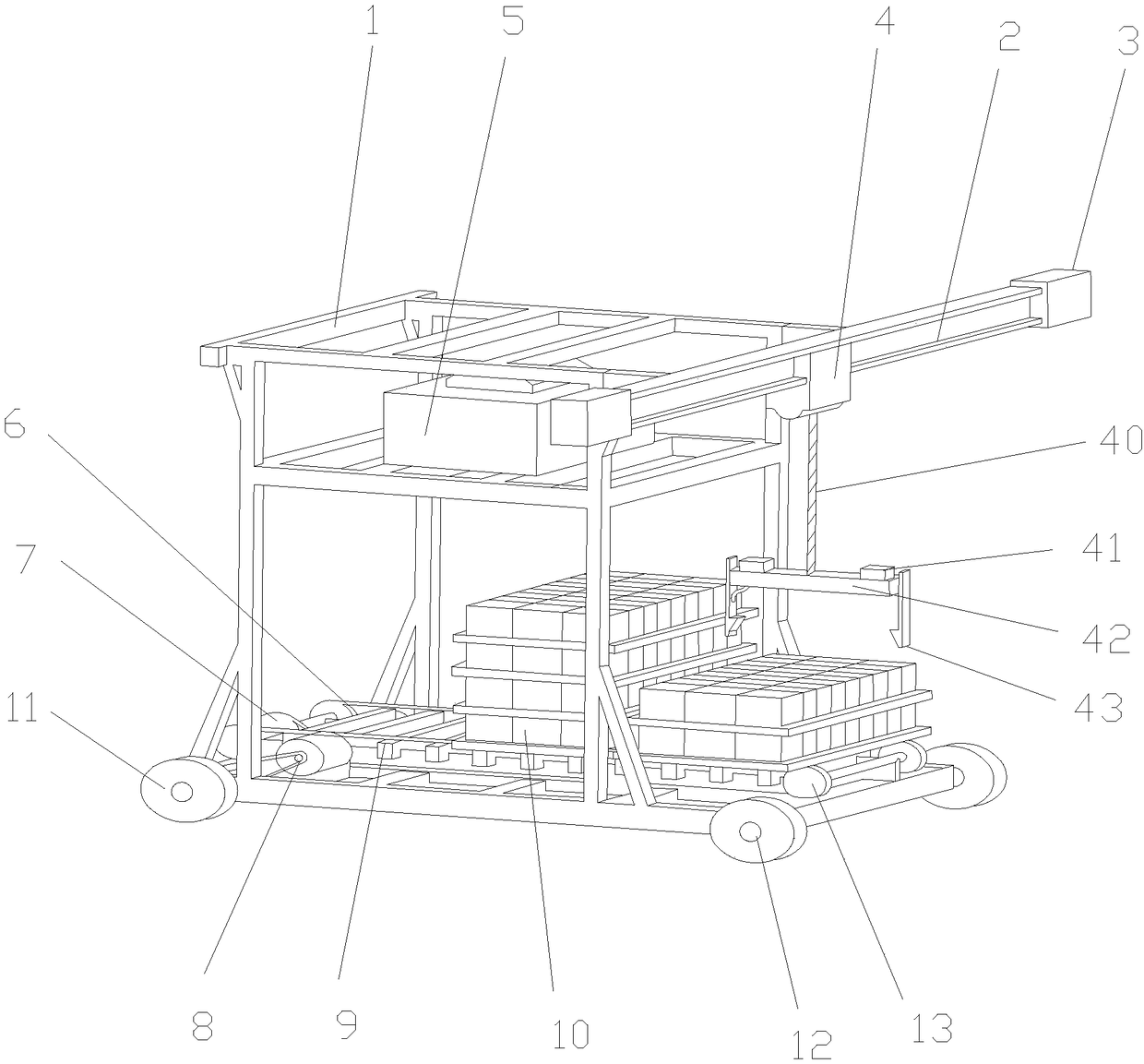

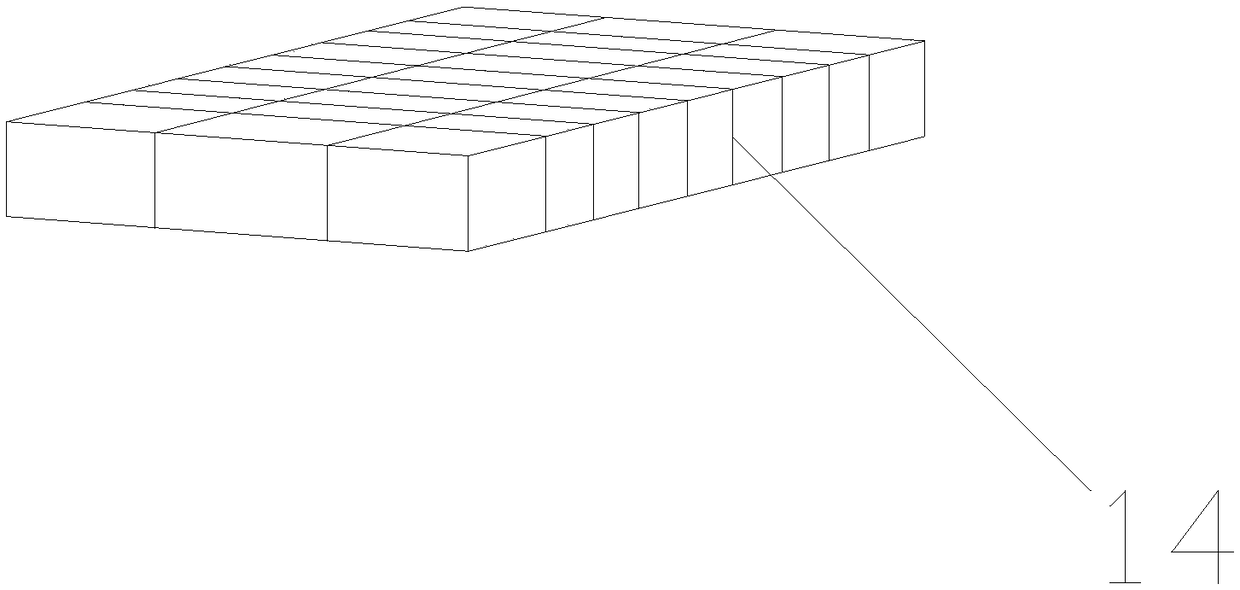

[0016] see Figure 1-3 , the present invention provides a technical solution: an automatic palletizer, the structure of which includes a pipe rigid equipment main body 1, a lifting beam 2, a lifting beam limit block 3, an automatic walking elevator 4, a brick clamp hydraulic pump station 5, Palletizer driving sprocket 6, chain drive turbine worm automatic stacking reducer 7, automatic walking worm gear reducer 8, stacker main frame 9, brick stacking 10, driving drive wheel 11, driven wheel 12 , the driven sprocket 13 of the stacker, the lifting workpiece 14, the separation pallet 15, the main body 1 of the pipe rigid equipment is fixedly connected with the lifting beam 2, and the lifting beam limit block 3 is arranged on the lifting beam 2 On bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com