Refinery plant byproduct C4 hydrocarbon and liquefied gas comprehensive processing and utilizing device and method

A technology for comprehensive processing of by-product carbon tetrahydrocarbons, applied in the directions of hydrocarbons, hydrocarbons, chemical instruments and methods, etc. The effect of energy consumption and investment, rational and smooth process design, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

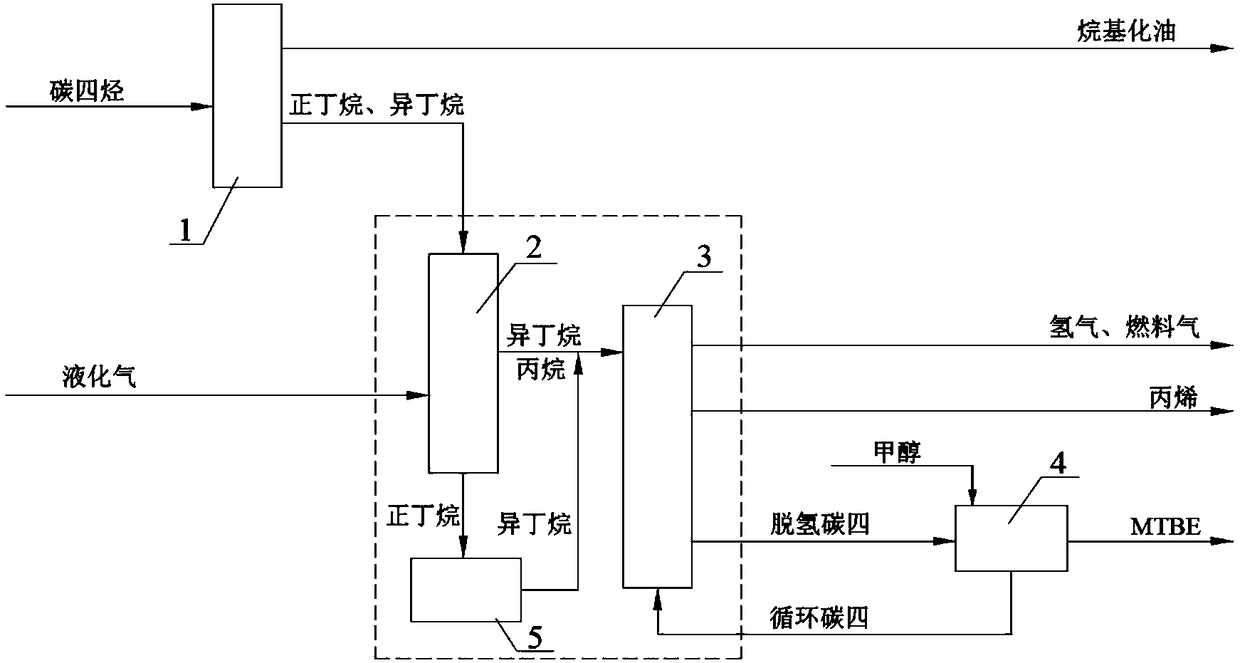

[0057] This embodiment provides a refinery by-product carbon tetrahydrocarbon and liquefied gas comprehensive processing and utilization device, such as figure 1 As shown, the comprehensive processing and utilization unit of C4 hydrocarbons and liquefied gas produced by the refinery includes an alkylation unit 1, a deisobutanizer 2, a propane-isobutane mixed dehydrogenation unit 3, an MTBE unit 4 and an isomerization unit. device 5. The alkylation unit 1, the deisobutanizer 2, the propane-isobutane mixed dehydrogenation unit 3 and the MTBE unit 4 are connected in sequence; The deisobutanizer 2 is connected with the isomerization unit 5; the isomerization unit 5 is connected with the propane-isobutane mixed dehydrogenation unit 3.

[0058] This embodiment also provides a method for comprehensive processing and utilization of by-product C4 hydrocarbons and liquefied gas in a refinery to produce high-octane gasoline component MTBE. operation, including the following steps:

[...

Embodiment 2

[0064] This implementation provides a light hydrocarbon comprehensive utilization project currently being implemented in a refinery, and two process configurations are designed. Table 4 shows the proportion of each feedstock component of light hydrocarbons in the refinery.

[0065] Table 4

[0066]

[0067]

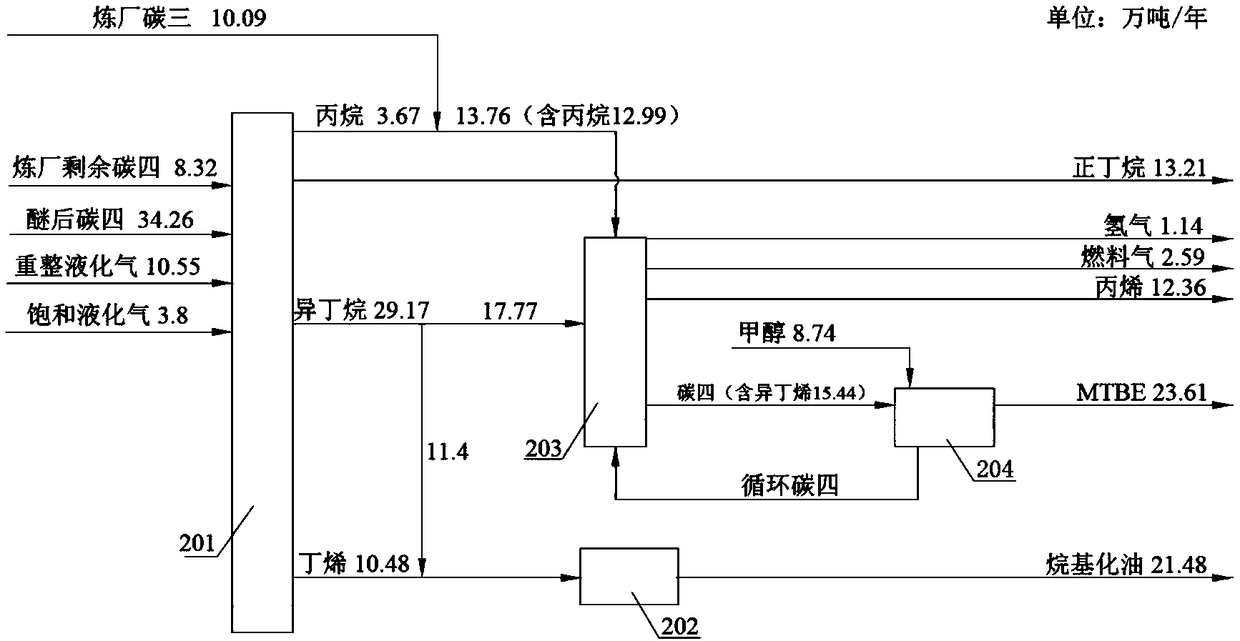

[0068] The schematic diagram of the original design process device is as follows: figure 2 As shown, it includes a raw material separation unit 201 , an alkylation unit 202 , a propane-isobutane mixed dehydrogenation unit 203 , and an MTBE unit 204 . The raw material separation device 201 is connected with the alkylation device 202 , the raw material separation device 201 is connected with the propane-isobutane mixed dehydrogenation device 203 , and the propane-isobutane mixed dehydrogenation device 203 is connected with the MTBE device 204 in circulation. Feedstock entry and product entry and exit of the unit figure 2 have been marked in detail and will not be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com