Preparation methods of welsh onion oil and dietary fibers of welsh onion

A technology of dietary fiber and scallions, applied in food preparation, food science, edible oil/fat, etc., can solve the problems of low deep processing of scallions, achieve good development and utilization prospects, realize comprehensive processing and utilization, and simple and easy process operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

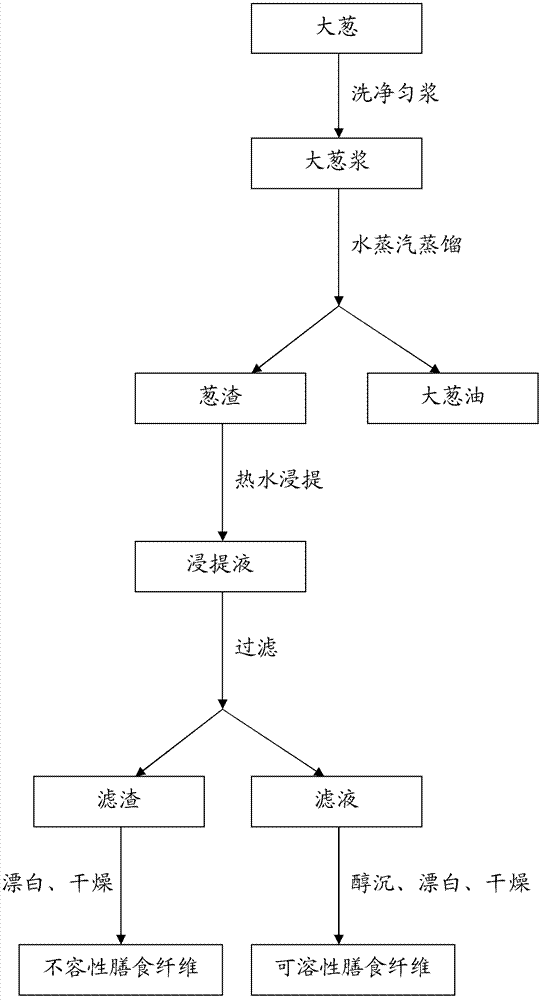

Method used

Image

Examples

Embodiment 1

[0025] (1) Wash and homogenize the fresh scallions;

[0026] (2) Take 500g of homogenate, add 1.5 times of water, steam distill at 106°C for 4h, collect volatile oil, anhydrous Na 2 SO 4 Remove residual water to obtain 1.0 g of pure shallot oil.

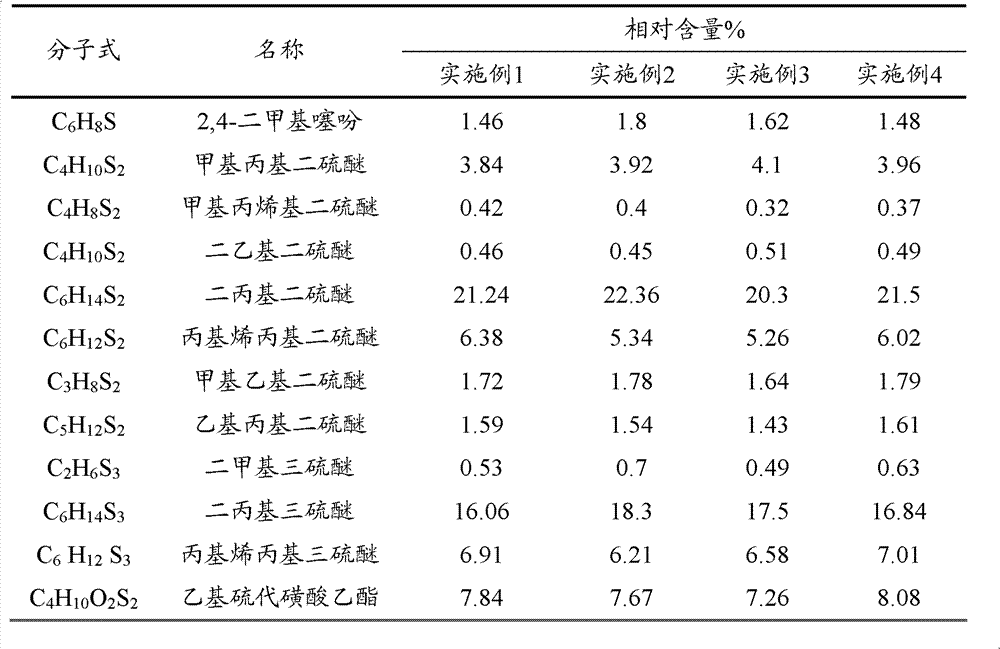

[0027] The extracted scallion oil is light yellow clear oil with little irritation and fresh scallion flavor, and the yield of scallion oil is 2.0‰. Detected by gas chromatography-mass spectrometry (GC-MS), the content of disulfide compounds in the shallot oil is 35.65%, the content of trisulfides is 23.5%, and the content of thiosulfonate is 7.84%. The specific components are shown in the table 1.

[0028] (3) Add water to the distilled green onion residue, the mass ratio of green onion residue to water is 1:1, extract at 50° C. for 4 hours, and filter to separate the filtrate and filter residue.

[0029] (4) 5 times of volume of 93% ethanol precipitation is added to the filtrate obtained in step (3), the precipitate is adjusted...

Embodiment 2

[0032] (1) Wash and homogenize the fresh scallions first,

[0033] (2) Take 500g of homogenate, add 2 times of water, steam distill at 103°C for 4.5h, collect volatile oil, anhydrous Na 2 SO 4 Remove residual water to obtain 1.1 g of pure shallot oil.

[0034] The extracted scallion oil is light yellow clear oil with little irritation and fresh scallion flavor, and the yield of scallion oil is 2.2‰. Detected by gas chromatography-mass spectrometry (GC-MS), the content of disulfide compounds in the shallot oil is 35.79%, the content of trisulfides is 25.23%, and the content of thiosulfonate is 7.67%. The specific components are shown in the table 1.

[0035] (3) Add water to the distilled green onion residue, the mass ratio of green onion residue to water is 1:2, extract at 55° C. for 5 hours, and filter to separate the filtrate and filter residue.

[0036] (4) 3 times of volume of 93% ethanol precipitation is added to the filtrate obtained in step (3), the precipitate is a...

Embodiment 3

[0039] (1) Wash and homogenize the fresh scallions;

[0040] (2) Take 500g of homogenate, add 2.5 times of water, steam distillation at 109°C for 5.5h, collect volatile oil, anhydrous Na 2 SO 4 Remove residual water to obtain 1.0 g of pure shallot oil.

[0041] The extracted scallion oil is light yellow clear oil with little irritation and fresh scallion flavor, and the yield of scallion oil is 2.0‰. Detected by gas chromatography-mass spectrometry (GC-MS), the content of disulfide compounds in the shallot oil is 33.43%, the content of trisulfides is 24.57%, and the content of thiosulfonate is 7.26%. The specific components are shown in the table 1.

[0042] (3) Add water to the distilled green onion residue, the mass ratio of green onion residue to water is 1:1.5, extract at 60° C. for 4.5 hours, and filter to separate the filtrate and filter residue.

[0043](4) 4 times of volume of 93% ethanol precipitation is added to the filtrate obtained in step (3), the precipitate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com