Method for comprehensively manufacturing biomass

A comprehensive processing and biomass technology, applied in the field of comprehensive biomass processing, can solve the problems of difficult dust removal, poor economy, poor adaptability of raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

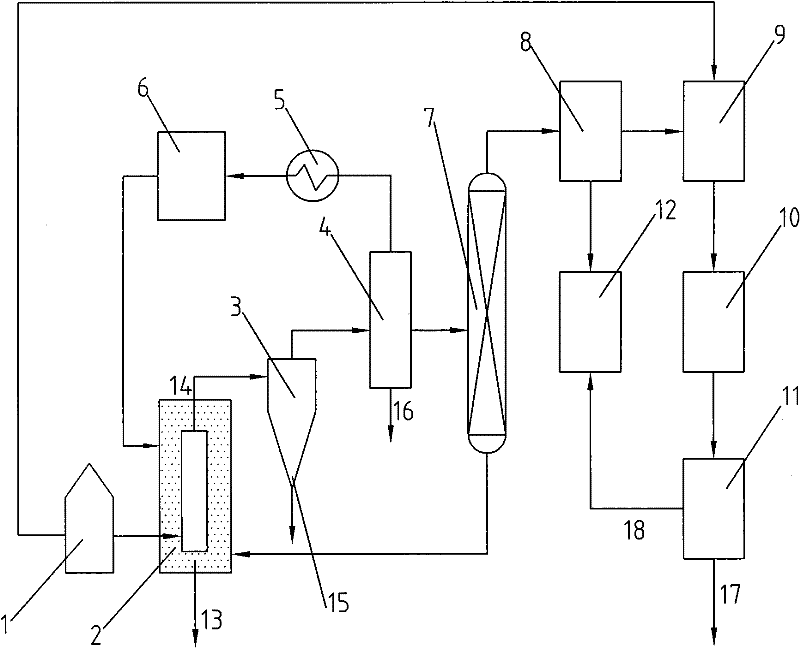

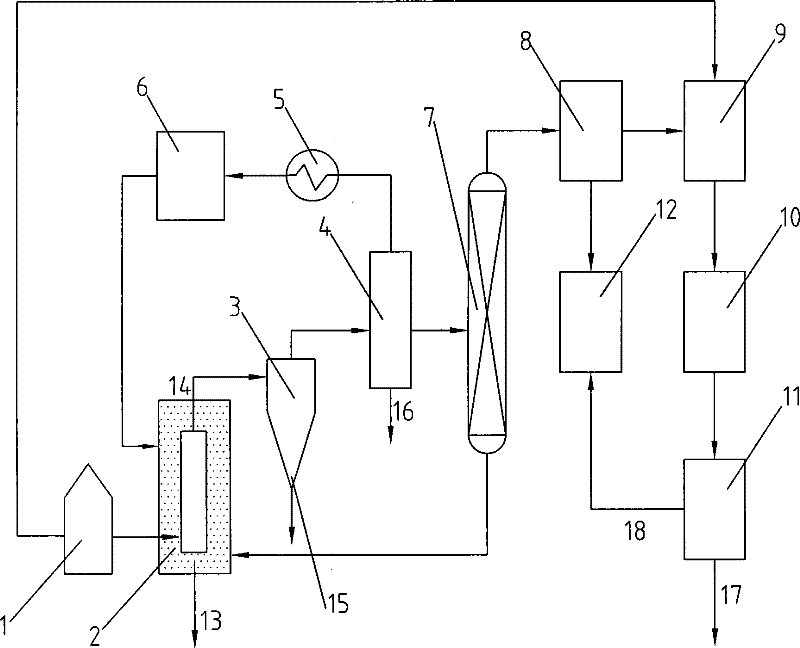

[0014] The invention uses cotton stalks as raw materials, and the cotton stalks are pulverized by a pulverizer into a particle size of <5 mm and a water content of <15%, and are fed into a moving bed cracking furnace at a feed rate of 1 ton / hour, and the cracking reaction takes 15 minutes at a cracking temperature of 550°C. , pyrolysis to produce charcoal and pyrolysis gas, wherein the charcoal is 57% of the weight of the straw, and the pyrolysis gas is 43% of the weight of the straw. After the dust is removed by the separator and washing tower, it is cooled to 100°C. After cooling, it is sent to the gas cabinet 6 and used as pyrolysis fuel. The liquid after the cracking gas is dedusted is separated into wood acetic acid and tar by the plate fractionation tower. The temperature at the bottom of the tower is 200°C. The temperature at the top of the tower is 20°C, the tar is directly sent to the cracking furnace as fuel, and the wood acetic acid is sent from the top of the tower ...

Embodiment 2

[0016] The invention uses cotton stalks and rice stalks as raw materials, and the cotton stalks are pulverized by a pulverizer into a particle size of <5 mm and a water content of <15%, and the pulverized cotton stalks are fed into a fluidized bed cracking furnace at a feed rate of 1 ton / hour. Cracking reaction at a temperature of 600°C for 13 minutes to produce charcoal and pyrolysis gas. Among them, the pyrolysis gas is 45% of the weight of the straw, and the charcoal is 55% of the weight of the straw. to 100°C, cooled and sent to the gas cabinet, used as pyrolysis fuel, the liquid generated after the pyrolysis gas is dedusted is separated by plate fractionation tower 7 to separate wood acetic acid liquid and tar, wherein, by weight, wood acetic acid liquid is 80%, tar 20%, the temperature at the bottom of the tower is 200°C, and the temperature at the top of the tower is 20°C. The tar is directly transported to the cracking furnace as fuel, and the wood acetic acid is sent t...

Embodiment 3

[0018]The present invention uses corn stalks as raw materials, and the corn stalks are pulverized by a pulverizer into a particle size of <10mm and a water content of <15%, and the straws are fed into a moving bed cracking furnace at a feed rate of 1 ton / hour, with a cracking temperature of 450°C and a cracking reaction of 10 Minutes, pyrolysis generates charcoal and pyrolysis gas, wherein charcoal is 58% of the straw weight, cracked gas is 42% of the straw weight, charcoal is discharged from the charcoal outlet of the moving bed cracking furnace for combustion, and the pyrolysis gas is separated and separated by the cyclone separator. The washing tower removes the dust and cools to 80°C. After cooling, it is sent to the gas cabinet 6 to be used as pyrolysis fuel. The liquid generated after the pyrolysis gas is dedusted is separated into wood acetic acid and tar through the plate fractionation tower. The temperature at the bottom of the tower is 150°C. The temperature is 40°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com