Protection device of cooling pipeline for high temperature gas delivery and gasification system using same

A technology for cooling pipelines and high-temperature gases, which is applied in the manufacture of combustible gases, granular/powdered fuel gasification, and the petroleum industry. It can solve problems such as damage to chilling devices, failure to detect double walls in time, and loss of coolant.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

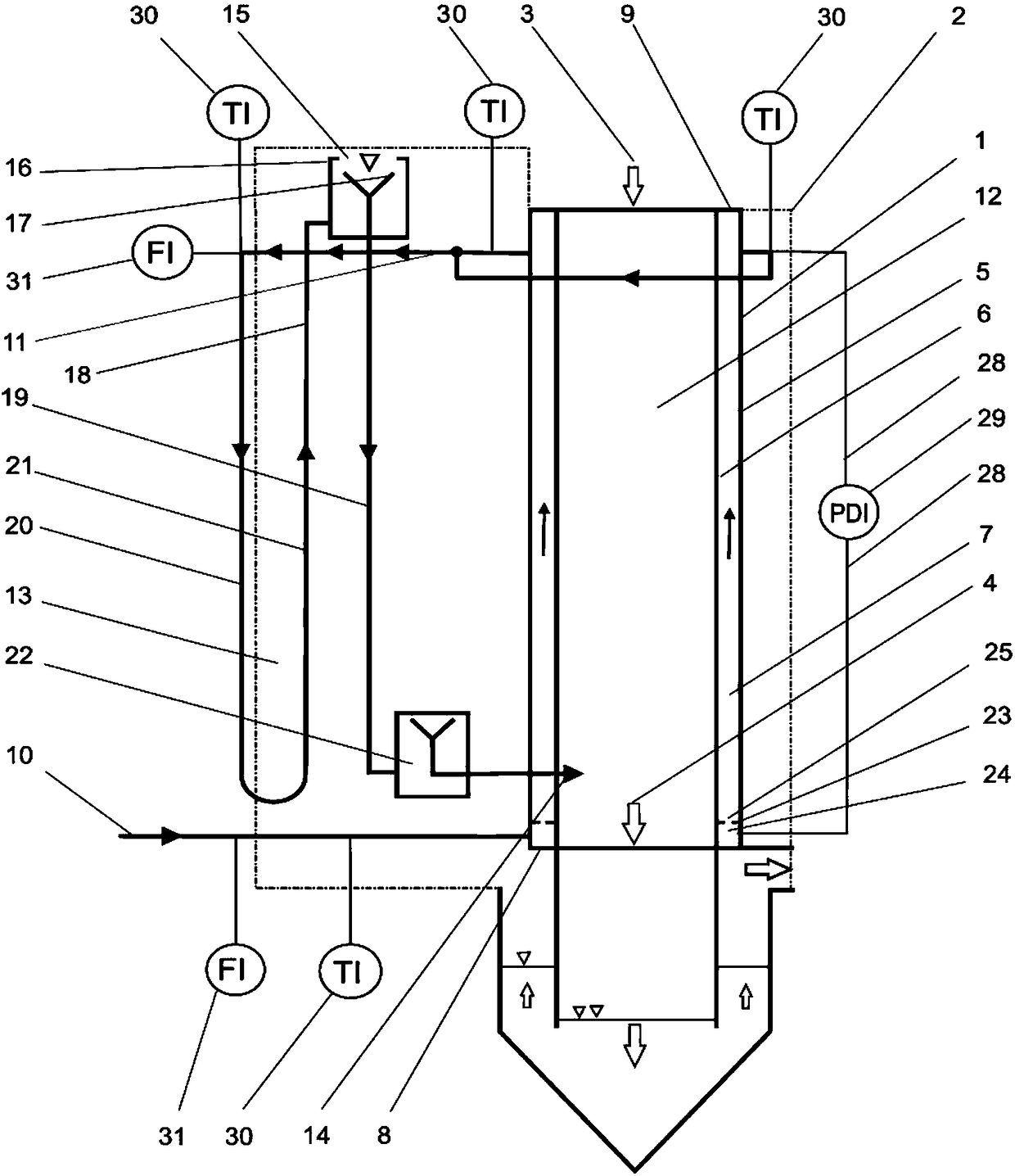

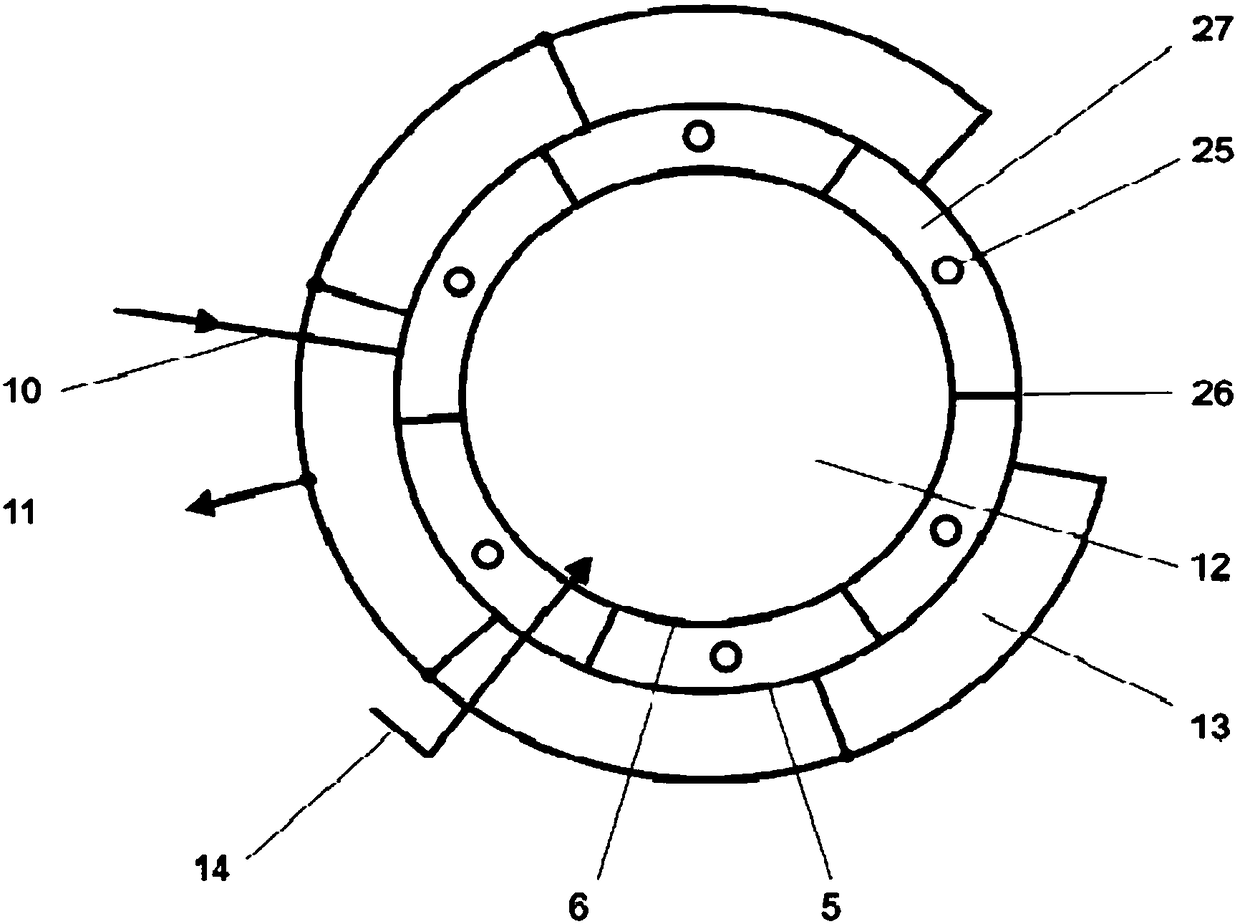

[0048] according to figure 1 , the protection device has an internal cooling downcomer 1, which is used for the high-temperature gas transportation of the downcomer quenching device, and is arranged concentrically with the vertical axis of the quenching device.

[0049] According to the intended use, the downcomer 1 has a top high-temperature gas inlet 3 and a bottom high-temperature gas outlet 4 . The inner space of the downcomer 1 is limited by the previous components, and high-temperature gas flows inside, which is defined as a high-temperature gas space 12 .

[0050] The space between the downcomer 1 and the pressurized outer wall 2 of the downcomer cooling device is defined as an external space 13 .

[0051] The downcomer chiller belongs to, for example, a coal gasification reactor designed as an entrained-flow gasifier, which produces synthesis gas from pulverized coal at high temperature and high pressure. The synthesis gas outlet of the gasification reactor is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com