Device and method for detecting vapor deposition alignment effect

A detection device and alignment device technology, applied in the field of evaporation, can solve the problems of increased production costs, waste of substrates and evaporation materials, and decreased production yield, so as to save production costs, improve evaporation yield, The effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

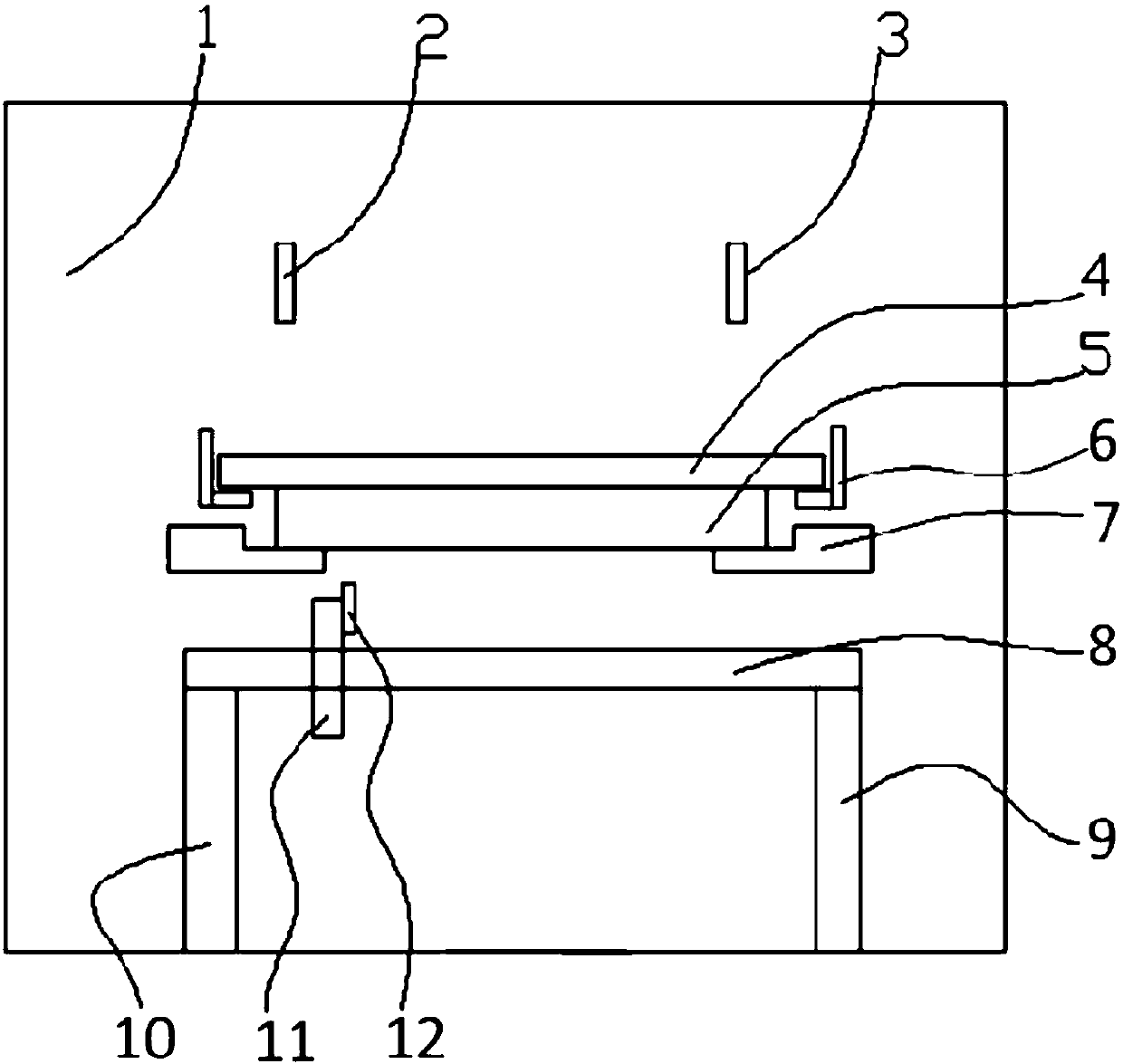

[0030] This embodiment provides a vapor deposition alignment effect detection device, such as figure 1 As shown, it includes a clean chamber 1 simulating a vacuum evaporation environment and an alignment device 2 and an alignment device 3 located in the clean chamber 1, a substrate substrate 4, a mask plate 5, and a substrate substrate support platform 6 , mask plate support platform 7 and alignment effect detection device, described alignment effect detection device is arranged on the described mask plate below, and described alignment effect detection device includes detection CCD camera 12, detection camera fixture 11, detection The moving guide shaft 8 of the camera fixing part and the moving guide rail 9 and the guide rail 10 of the guiding shaft of the detection camera fixing part are fixed in the clean chamber 1 . The guide shaft 8 of the detection camera fixing part can move along the front and rear directions of the guide rail 9 and the guide rail 10 under the drive o...

Embodiment 2

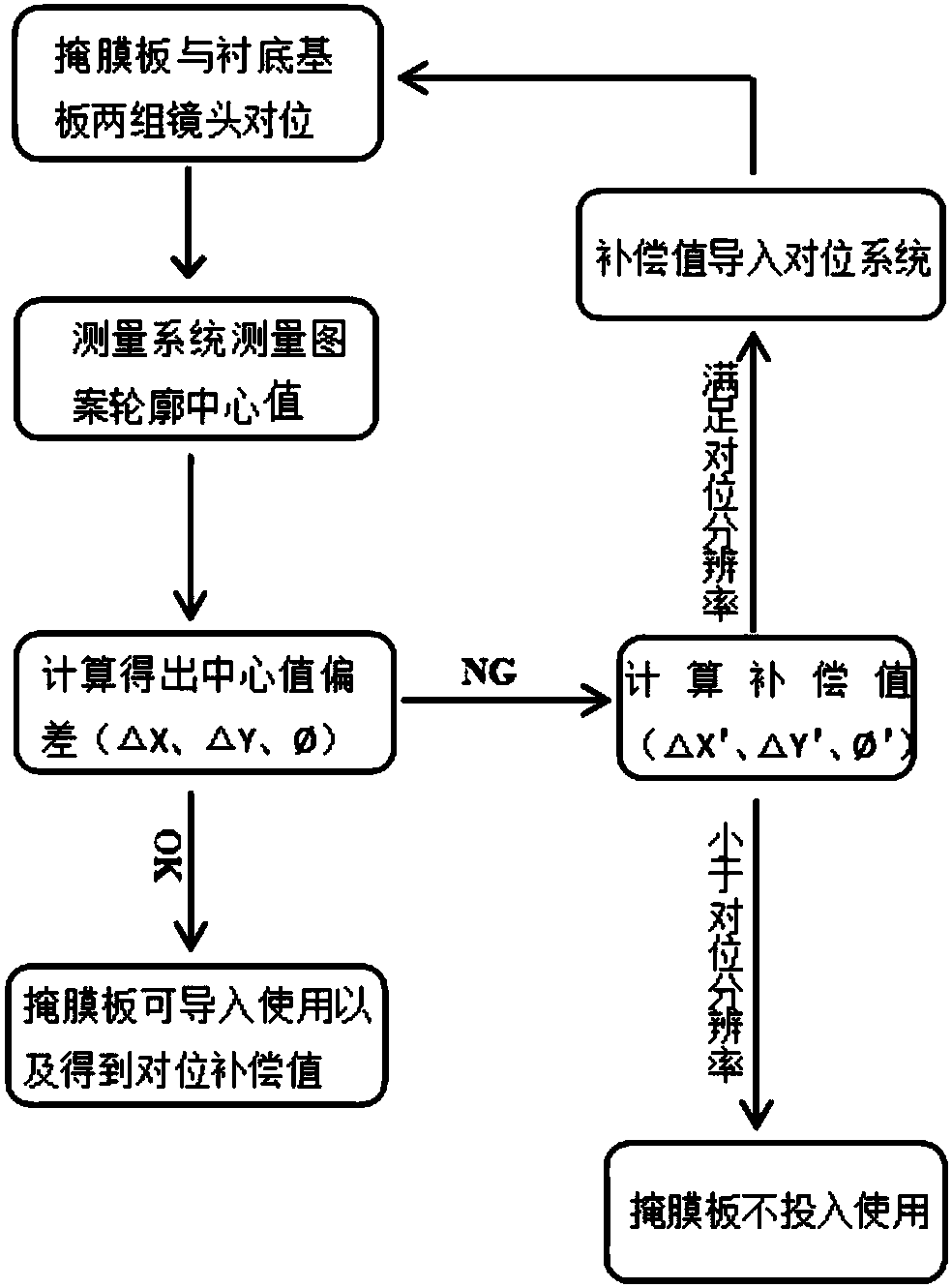

[0034] The present invention also provides a method for detecting the alignment effect of vapor deposition, such as image 3 shown, including:

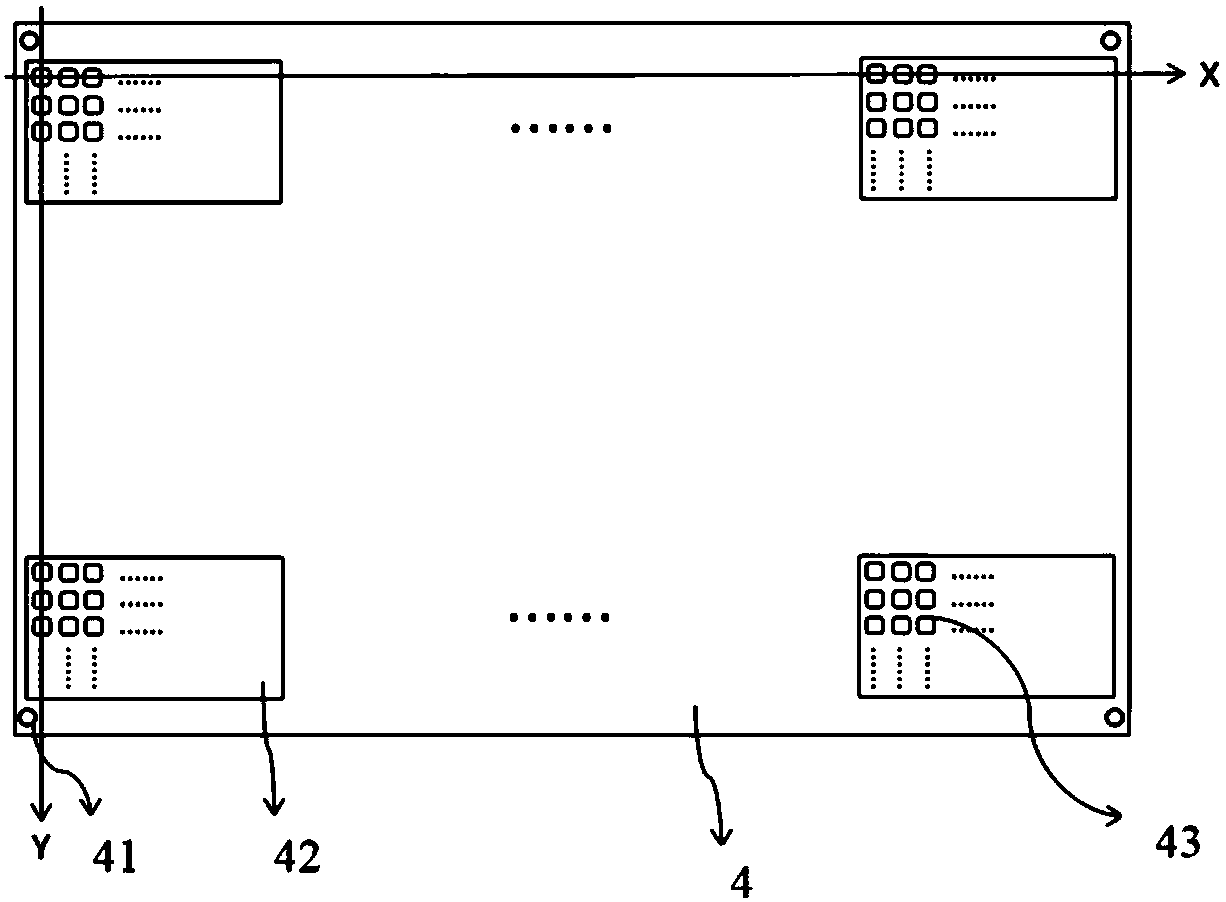

[0035] An alignment device is used to align the mask plate and the base substrate, and the alignment device includes two groups, and each group is composed of two cameras. Such as figure 2 As shown, the camera of the alignment device performs alignment by identifying whether the positioning holes on the mask plate coincide with the positioning holes on the base substrate.

[0036] The alignment effect detection device performs pattern recognition on the mask plate and the substrate substrate after the alignment is completed, and the detection camera of the alignment effect detection device starts to measure the center of the opening pattern outline of the mask plate and the pattern center of the substrate substrate ; The detection camera will measure the opening contours and anode patterns of multiple adjacent masks at one time, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com