Antibacterial warm-keeping self-cleaning shirt fabric

A self-cleaning, fabric technology, applied in shirts, anti-staining/anti-fouling fibers, textiles, etc., can solve the problems of inability to spread, poor air permeability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

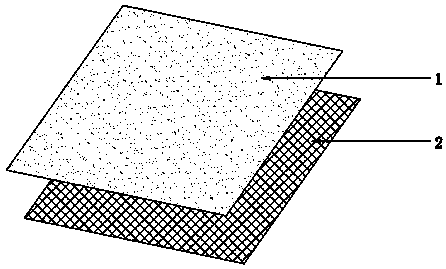

[0027] see figure 1 , the specific embodiment adopts the following technical scheme: a kind of self-cleaning shirt fabric of antibacterial and warm, it comprises nano-titanium dioxide layer 1 and fabric base cloth 2, and the surface of fabric base cloth 2 is closely attached with nano-titanium dioxide layer 1.

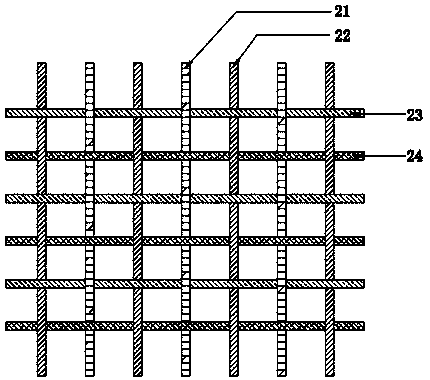

[0028] see figure 2 , the fabric base fabric 2 is made of warp one 21, warp two 22, weft one 23, and weft two 24; the warp one 21 is made of wool fiber and lyocell fiber line; the warp two 22 is an anti-pilling acrylic thread; the weft one 23 is a line formed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com