A drum with a self-cleaning function, a washing machine and a washing method

A self-cleaning, washing machine technology, applied in the field of washing machines, can solve the problems of secondary pollution of washing clothes, less water consumption for washing, etc., and achieve the effects of good washing effect, ensuring stability, and good market promotion value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

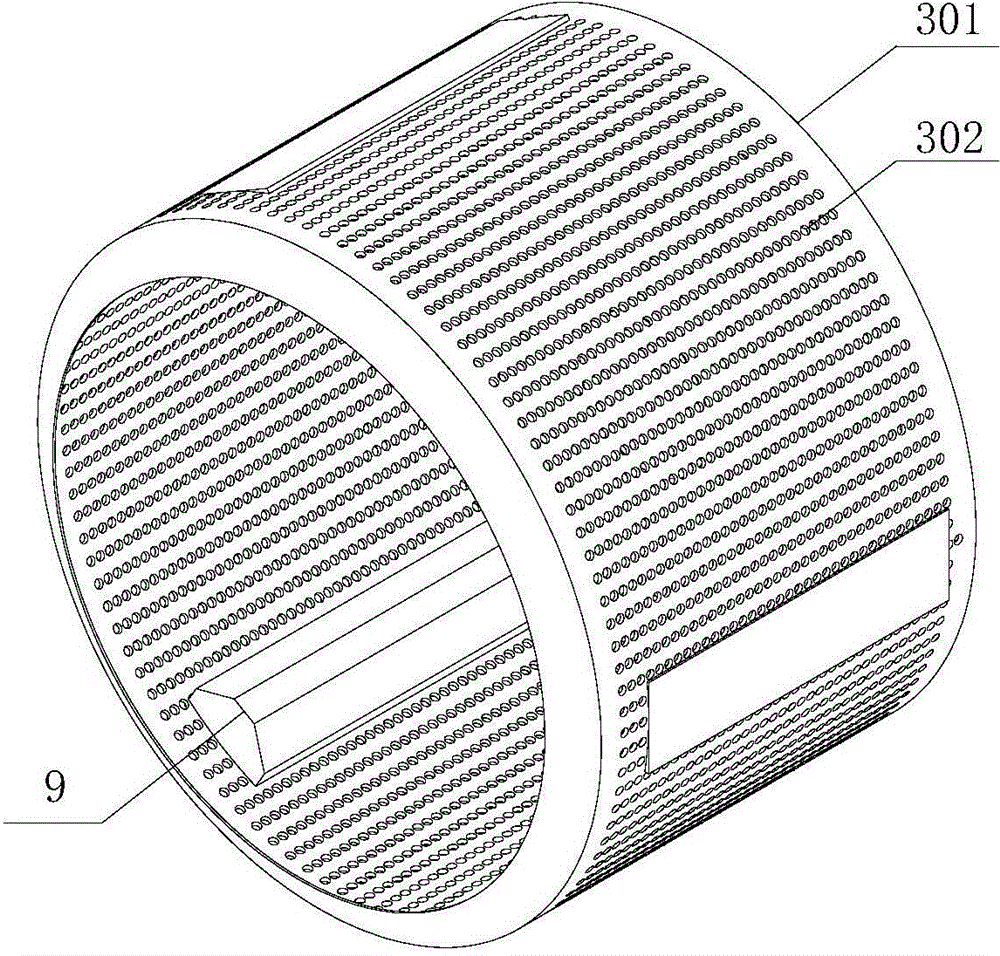

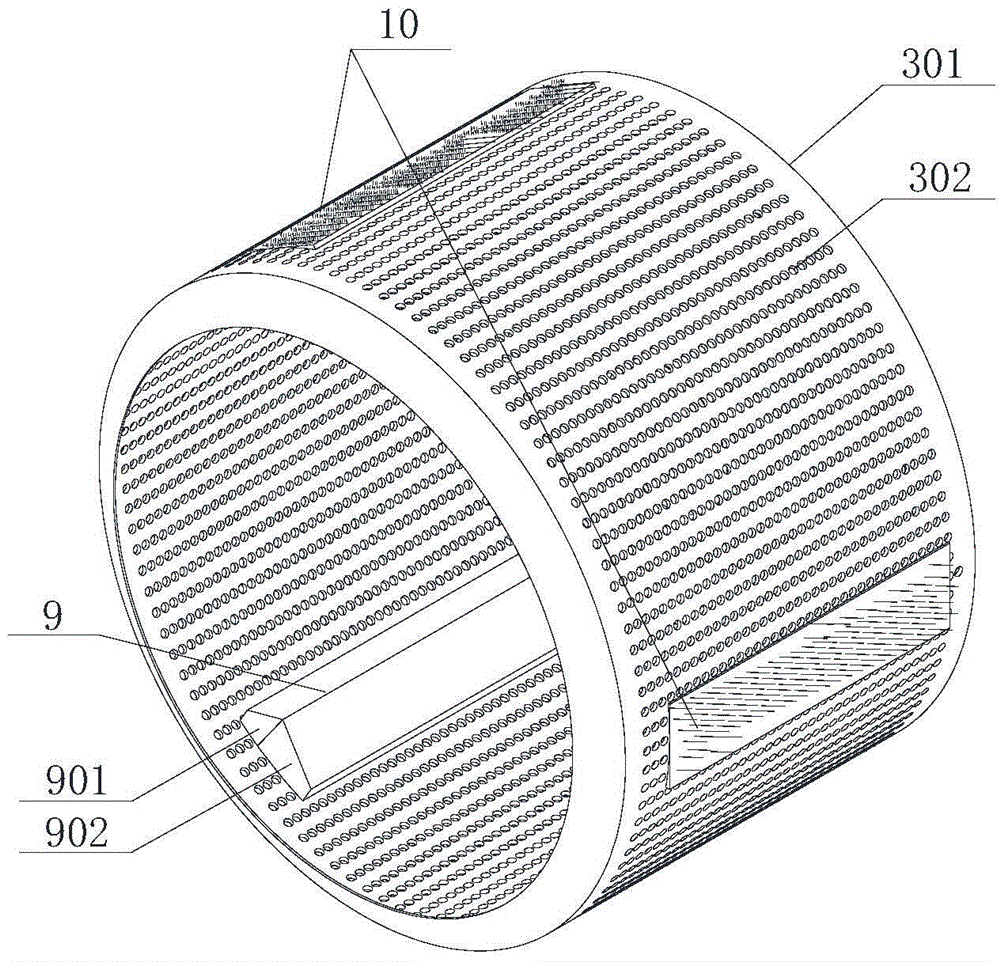

[0064] Such as Figure 6 and Figure 7 As shown, the difference between this embodiment and the above-mentioned embodiments is only that: the side of the first lifting device 901 in this embodiment that is in contact with the second lifting device 902 is an arc-shaped concave surface, and the side of the second lifting device 902 that is in contact with the second lifting device 902 is an arc-shaped concave surface. The contact side of a lifting device 901 is an arc-shaped convex surface; the arc-shaped convex surface moves along the arc-shaped concave surface to realize the contact / separation between the second lifting device 902 and the inner wall of the outer cylinder 2 .

[0065] This makes the arc contact between the first lifting device 901 and the second lifting device 902, and the second lifting device 902 moves along the arc surface, so that the two are always in contact during the movement, preventing Clothes are pinched due to the gap generated between the rotation...

Embodiment 2

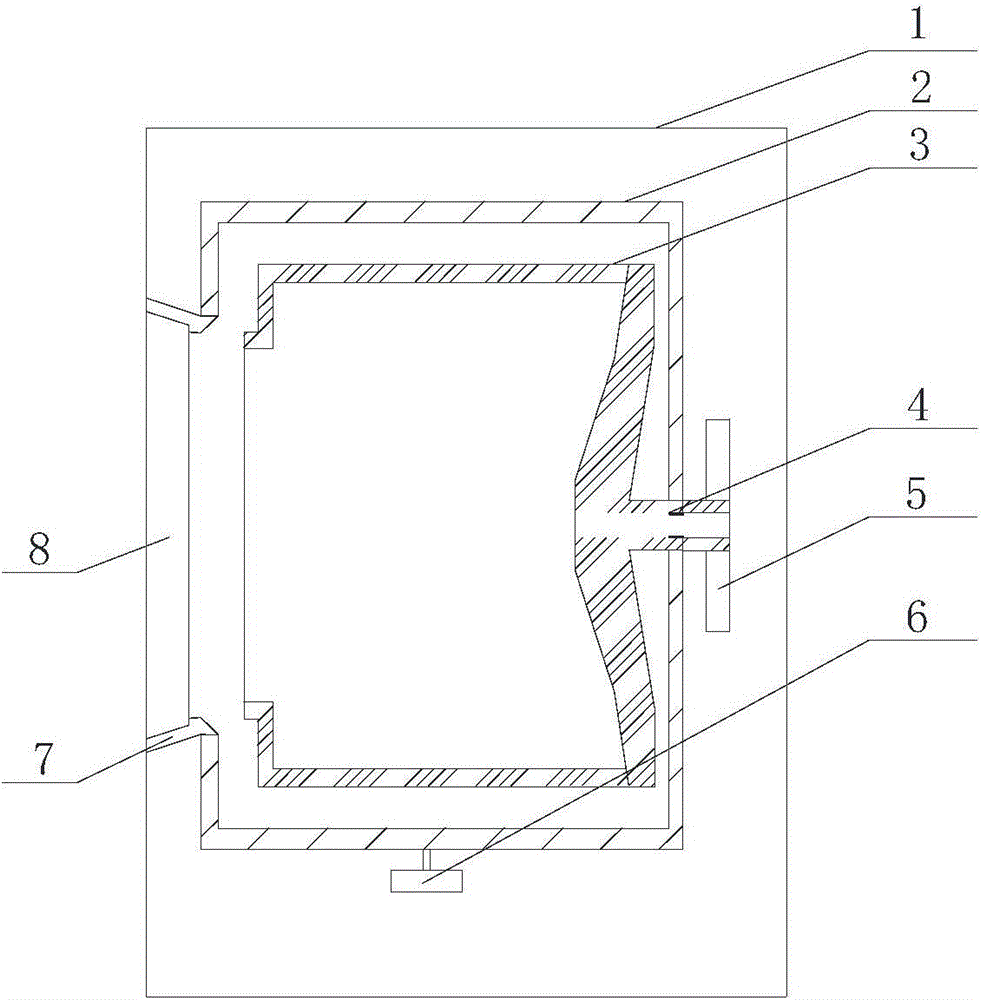

[0067] This embodiment provides a washing machine with a drum with a self-cleaning function as described in the above specific embodiments, including an outer drum 2, a drum 3 with a self-cleaning function, and the drum 3 is coaxially installed inside the outer drum 2 and can rotate freely. The lifting device 9 includes a plurality and is installed along the axial direction of the drum 3, the second lifting device 902 has only one force bearing surface set towards the clockwise rotation direction of the drum, and the second lifting device 902 has at least A force bearing surface is provided towards the anticlockwise rotation direction of the drum.

[0068] The invention of the washing machine of this embodiment can realize self-cleaning of the inner wall of the outer cylinder 2 during the washing and / or rinsing process, and can effectively avoid the residue of dirt, mold, virus and other impurities on the inner wall of the outer cylinder 2 of the drum washing machine. Therefor...

Embodiment 3

[0073] This embodiment provides a kind of washing method, described washing method is used in the washing machine of embodiment 2, specifically, comprises the following technical scheme:

[0074] A laundry method, in the washing and / or rinsing program, the drum 3 rotates alternately in two directions, and the time for the drum 3 to rotate in one direction is longer than the time for the drum 3 to rotate in the other direction; in the dehydration program, the drum 3 only Perform one-way high-speed rotation.

[0075] Specifically, in the laundry method of this embodiment, in the washing and / or rinsing procedure, the drum 3 rotates clockwise and counterclockwise alternately, the time for the drum 3 to rotate clockwise is greater than or equal to 3 / 4T, and the drum 3 rotates counterclockwise The time is less than or equal to 1 / 4T. In the dehydration program, the drum 3 runs clockwise at high speed;

[0076] When the drum 3 rotates clockwise, the first lifting device 901 lifts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com