Cement slurry clearance measuring assembly

A technology for cement slurry and channeling measurement, applied in construction and other directions, can solve the problems of cumbersome test operation, deviation of test results, inability to effectively simulate the actual situation, etc., and achieve the effect of avoiding gas channeling test errors and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

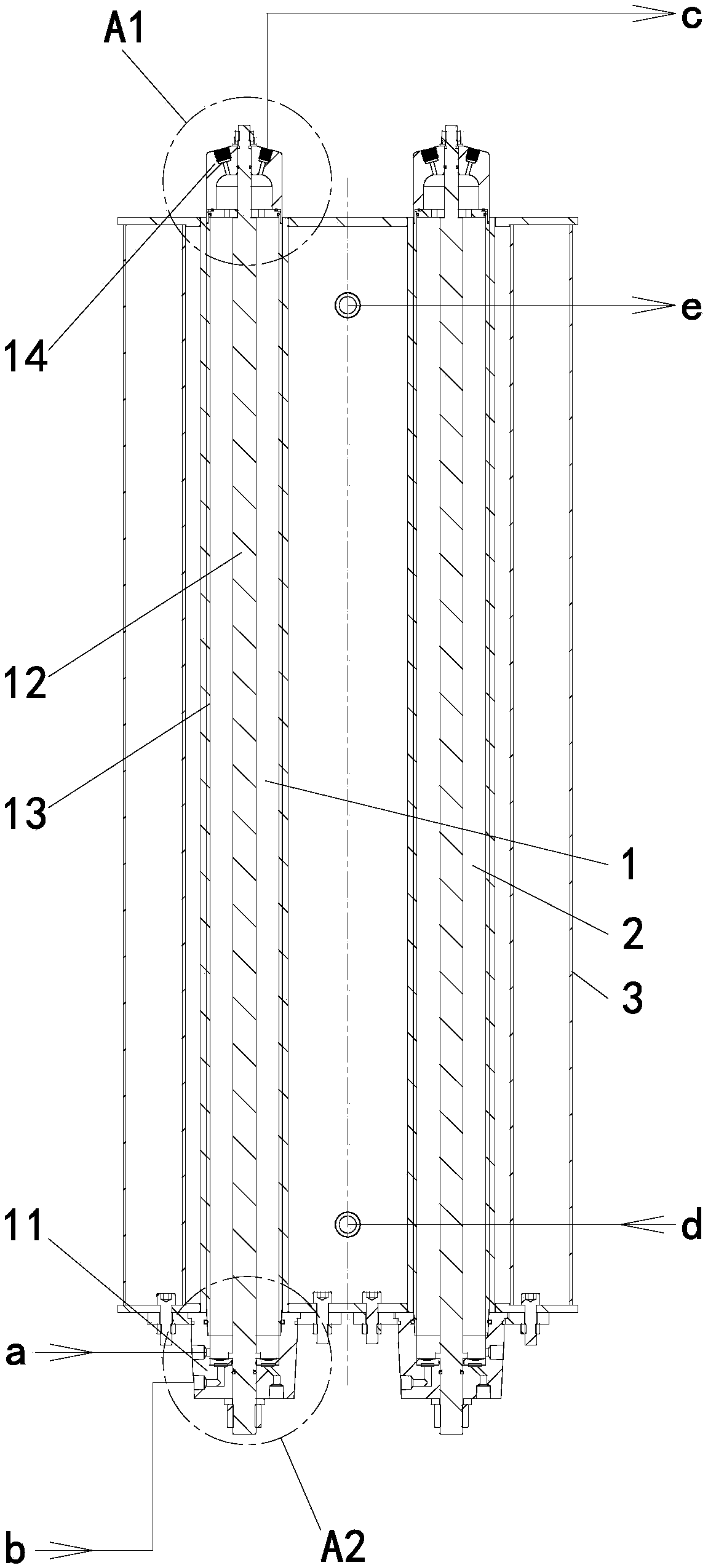

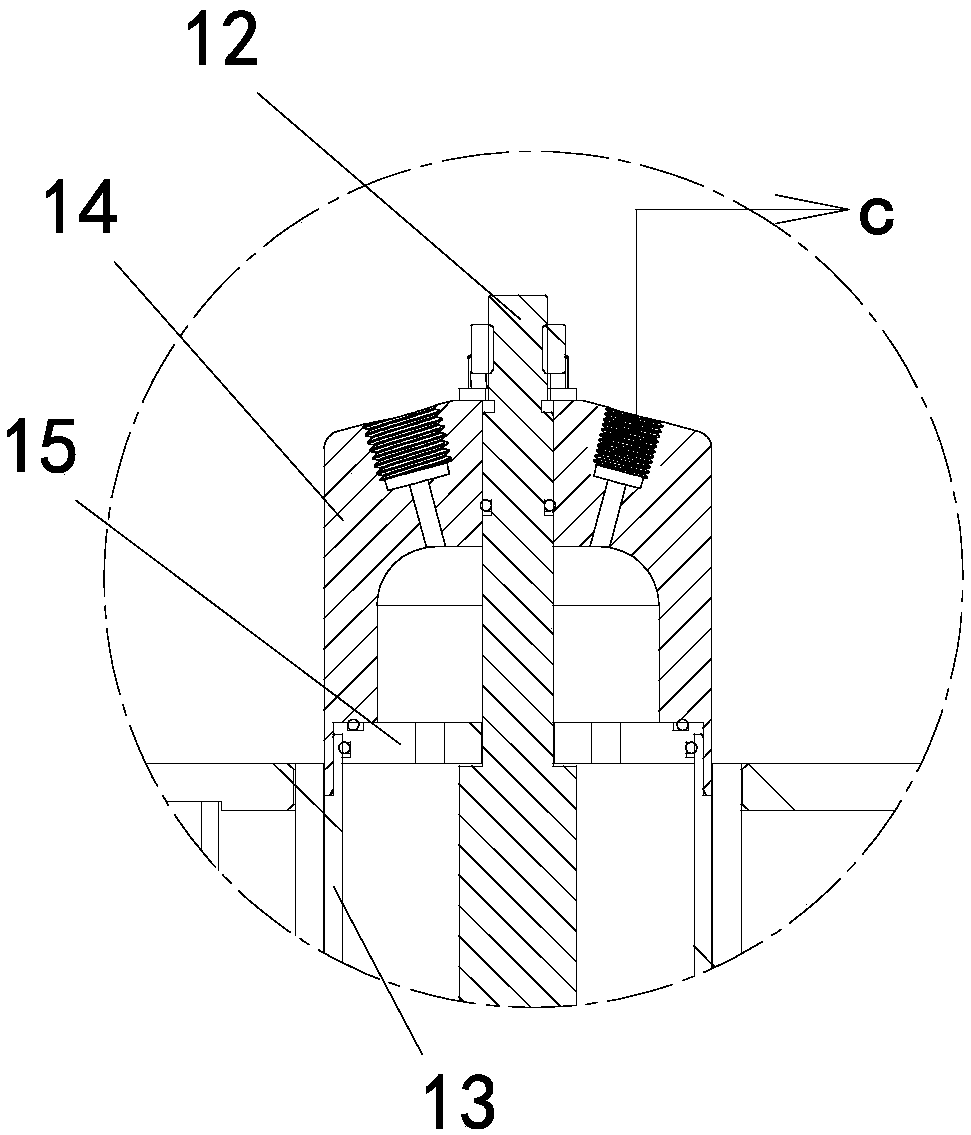

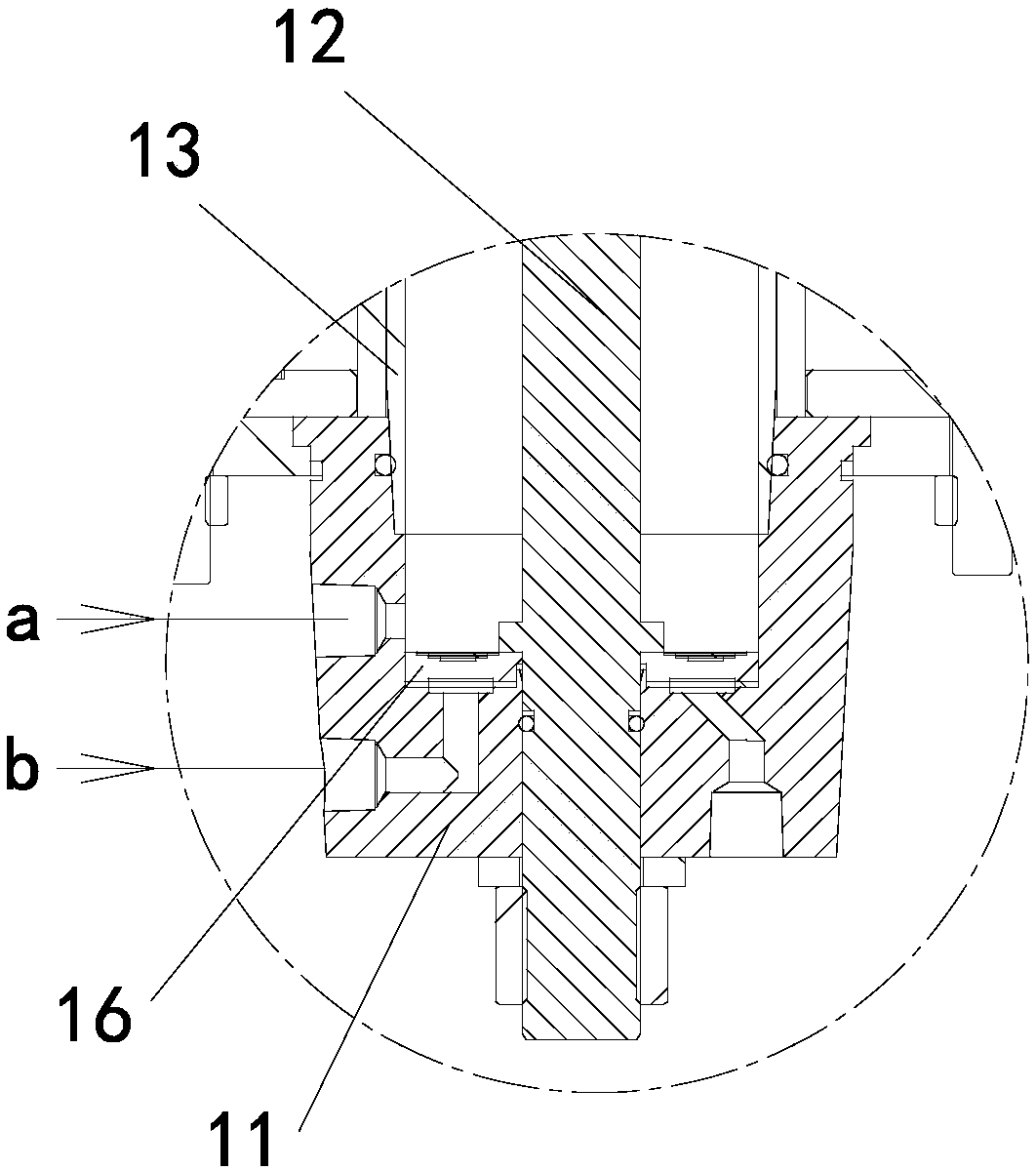

[0045] Embodiment 1 of the present invention provides a gas channeling simulation test device, which includes a heating cylinder and two cement slurry channeling measurement components arranged inside the heating cylinder; wherein, one of the two cement slurry channeling measurement components can be used as a gas channeling The gas channeling tube in the simulation test device, and the other can be used as the weightlessness tube in the gas channeling simulation device to cooperate together to complete the corresponding gas channeling simulation test operation.

[0046] Such as figure 1 As shown, the above gas channeling simulation test device may include a gas channeling tube 1 for measuring the gas channeling process of cement and a weight loss tube 2 for measuring the hydrostatic column pressure of cement; wherein, the gas channeling tube 1 and the weight loss tube 2 are all set In the heating cylinder 3, both the gas channeling tube 1 and the weightlessness tube 2 are pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com