Flexible method for detecting quality of curved surface of head of high-speed train

A quality inspection method, high-speed train technology, applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve the problems of blank high-precision inspection methods for large parts, and achieve complex surface inspection in space, easy storage, and inspection Informative and comprehensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

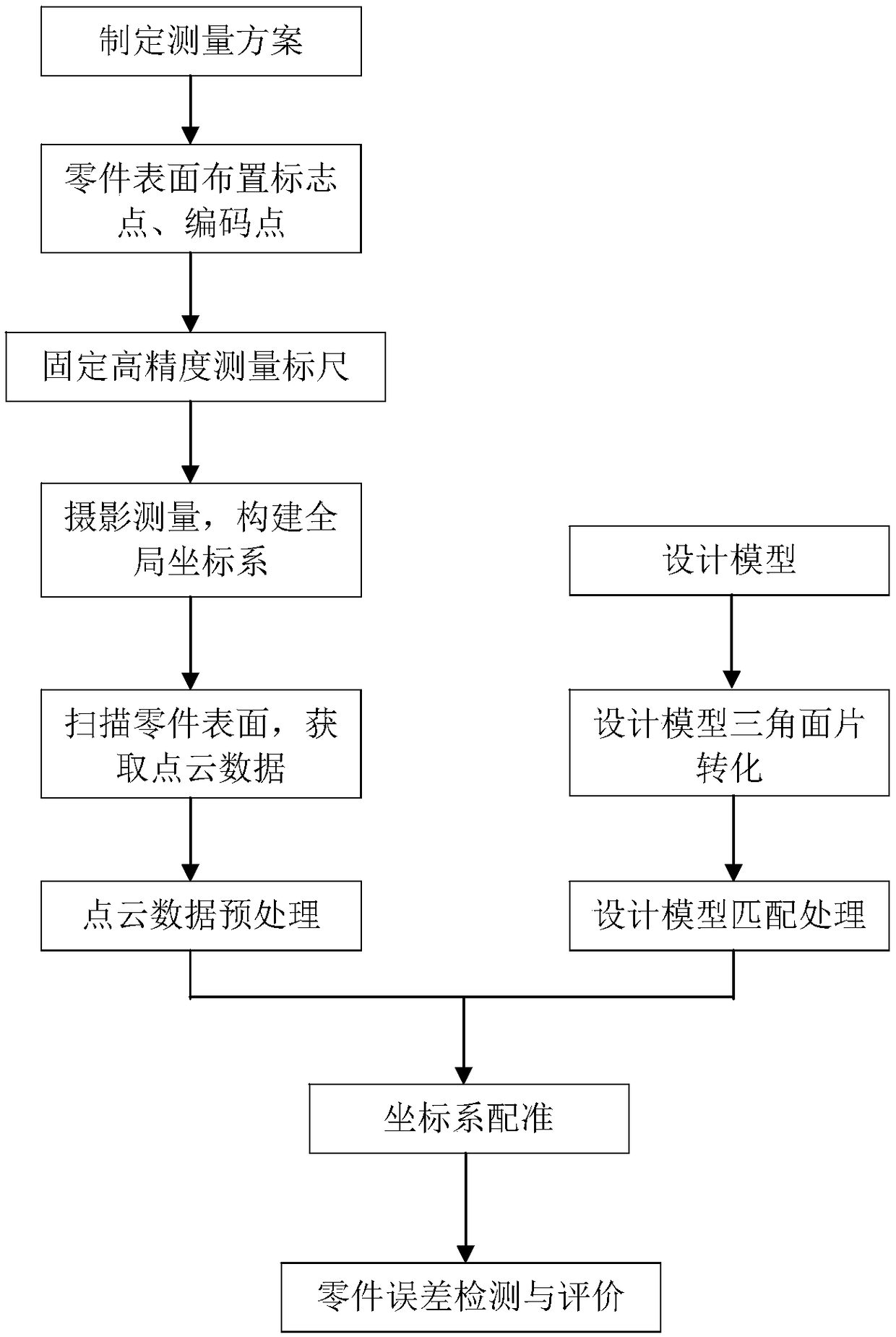

[0049] The specific implementation method comprises the following steps:

[0050] S1. Paste the mark points and code points on the surface of the tested part. The layout requirements of the mark points are: adjacent mark points, the distance between the two points is 5cm-10cm, arranged in an irregular triangle in random order, and do not Put it on the corner of the object.

[0051] In step S1, the marking point is a circular sticker with reflective material on the inner circle and a black circle on the outer circle; the coding point is a square tile with reflective material arranged irregularly inside.

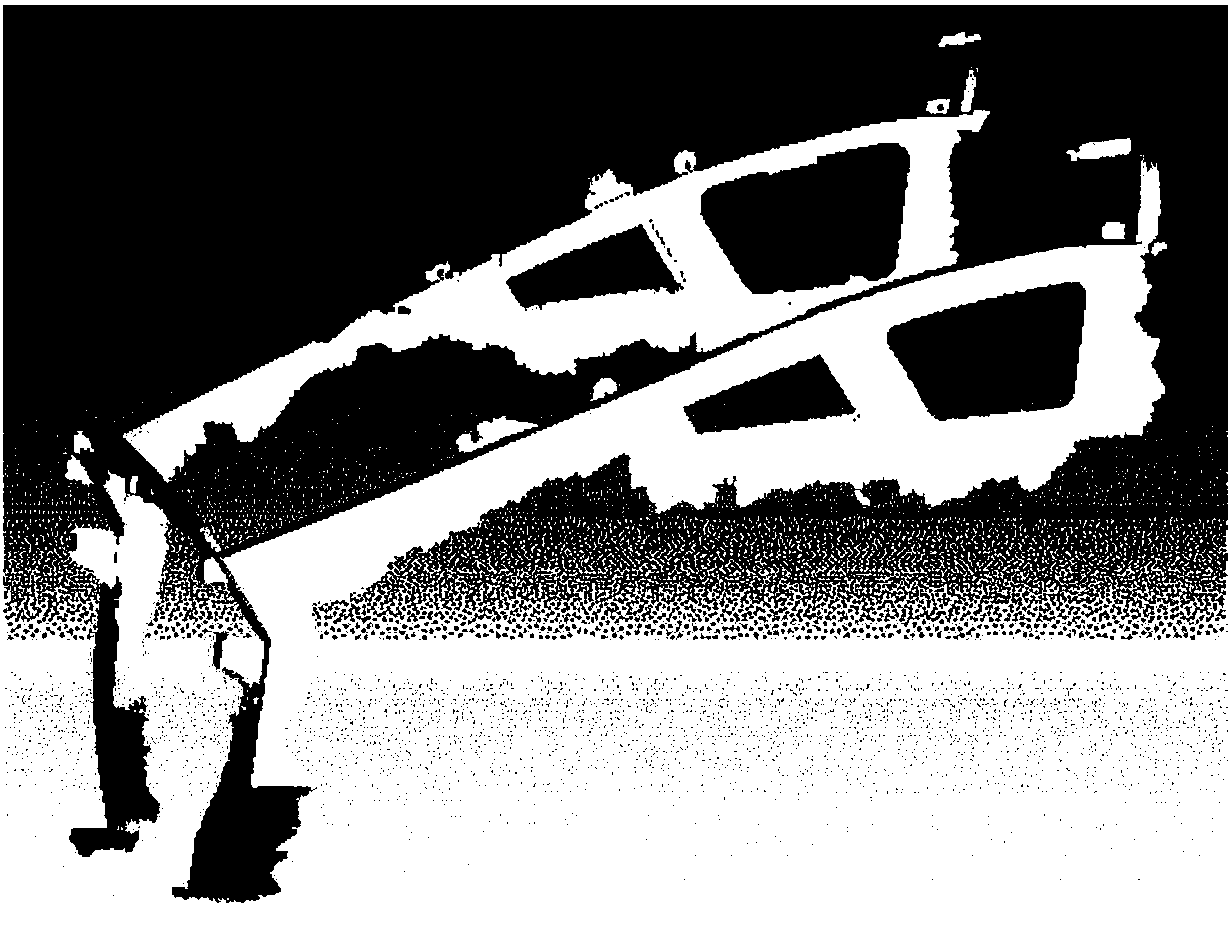

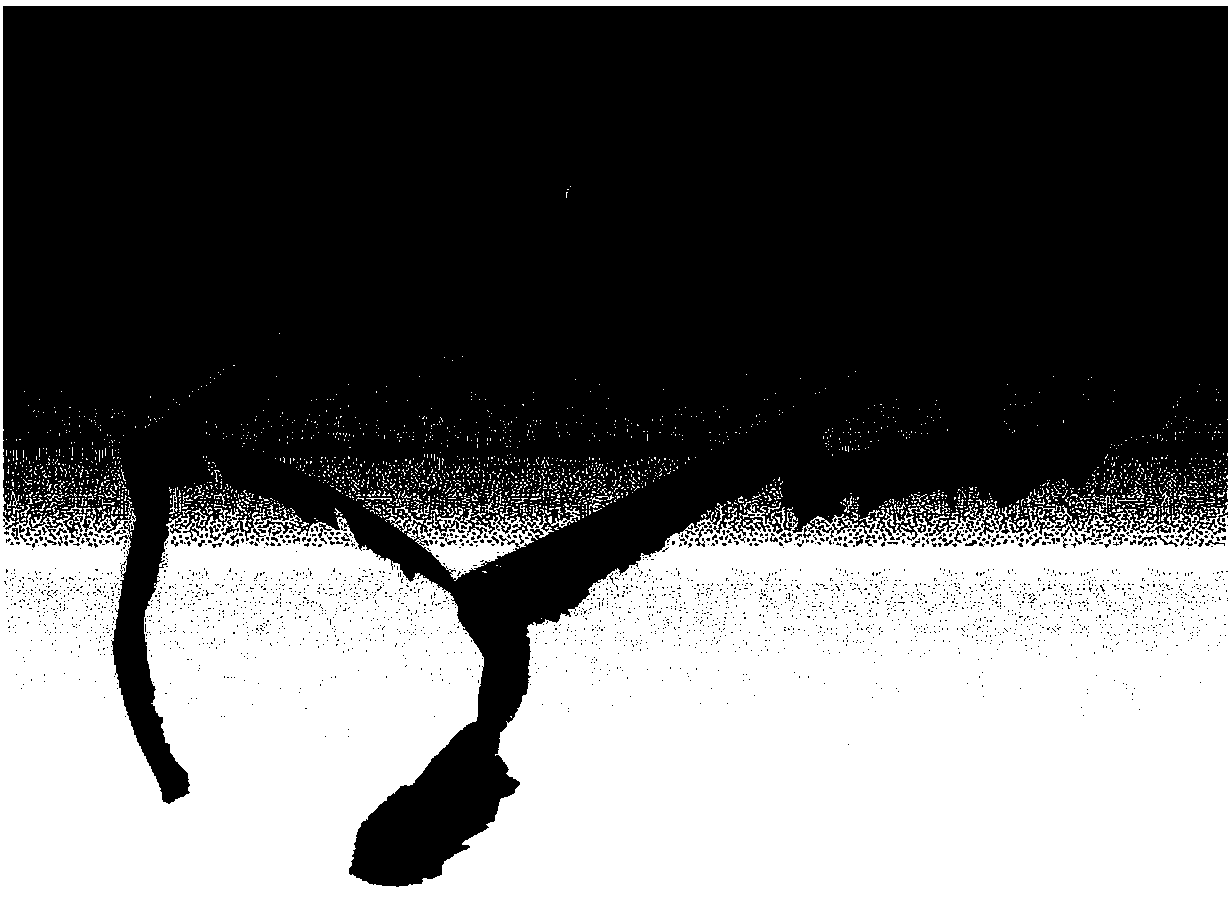

[0052] The part to be tested is a large frame part with a length exceeding 4 meters.

[0053] S2. Fix a high-precision measuring scale in the area to be scanned. The measuring scales should be placed perpendicular to each other and must be stable.

[0054] S3. Use the close-range three-dimensional photogrammetry system to take all-round and multi-angle shots of the measured ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com