Battery characteristic simulating control method

A technology of analog control and storage battery, applied in control/regulation system, measurement of electricity, regulation of electricity variables, etc., can solve the problems of unrealistic, high cost, and complicated calculation of experiments and research, saving purchase cost, flexible control, achieve simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

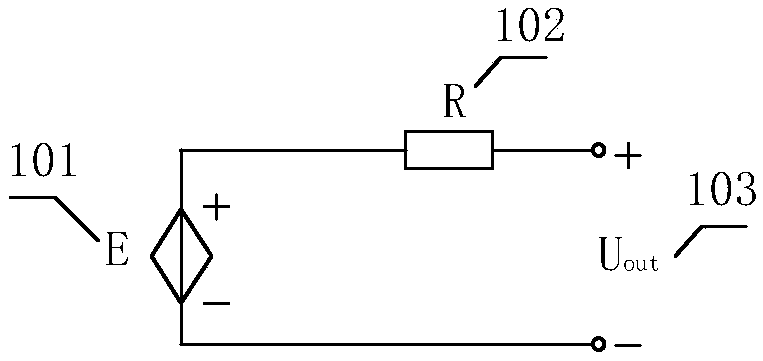

[0017] Such as figure 1 Shown, the battery model equivalent circuit of the present invention is as follows:

[0018] The battery model is equivalent to the voltage source series internal resistance form, where 101 represents the internal potential E of the battery, expressed in the form of a controlled voltage source; 102 is the internal resistance R of the battery, and the simulated output voltage U of the battery out is the internal potential E of the battery and the internal resistance voltage drop V R Sum. V R =i×R, where i is the battery current.

[0019] The present invention is as follows to the simulated control method of storage battery:

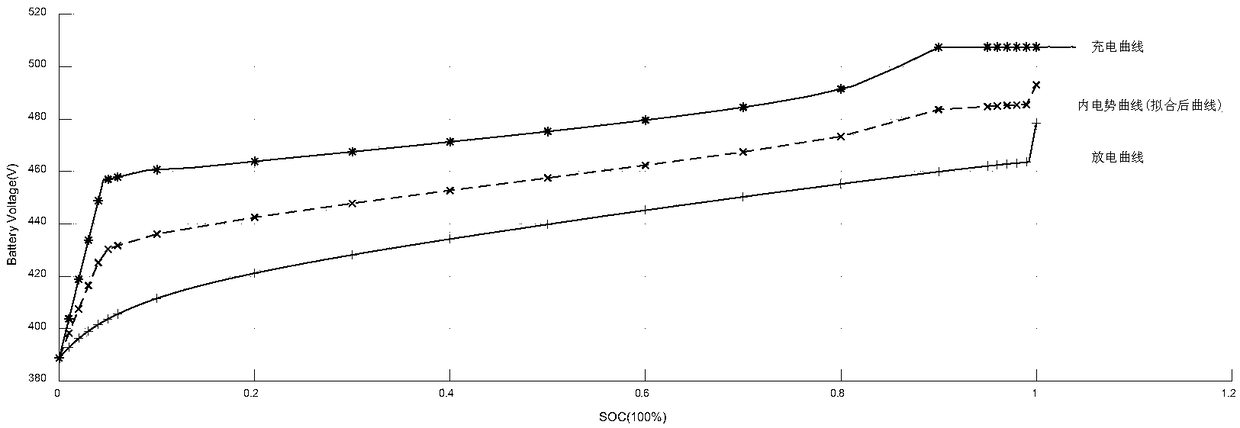

[0020] Firstly, the battery characteristic curve is fitted. According to the actual charging and discharging data of the battery, the curves of the charging and discharging state of charge SOC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com