LED flip chip with controllable light-emitting angle, and electronic equipment employing same

A light-emitting angle and flip-chip technology, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as difficult to achieve backlight uniformity and small light-emitting angle of chips, so as to increase or decrease the light-emitting angle and change the light-emitting angle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

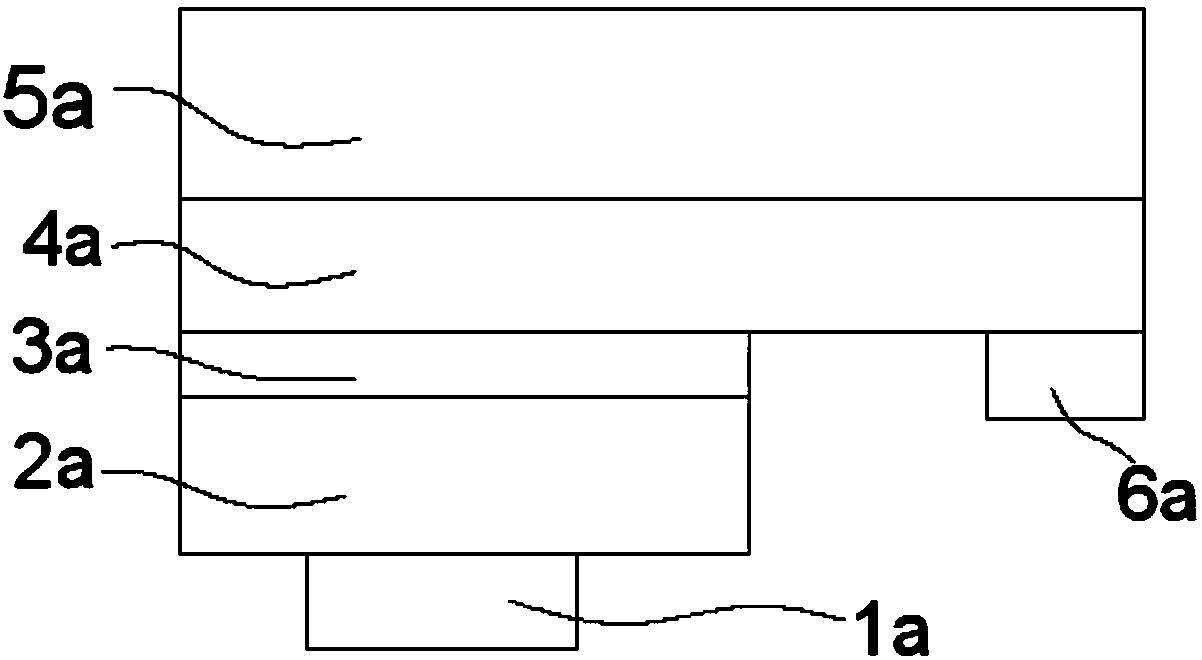

[0041] An LED flip-chip with a controllable luminous angle is applied to electronic equipment such as mobile phone backlight modules, backlight panel devices or electronic display devices. The electronic equipment is equipped with, for example, Figure 3 to Figure 5 , including a substrate 5, an N-type layer 4, a light-emitting layer 3 and a P-type layer 2, and from the substrate 5, the N-type layer 4, the light-emitting layer 3 and the P-type layer 2 are sequentially stacked in layers, And a P electrode 1 is provided on the P-type layer 2, and an N-electrode 6 is provided on the N-type layer 4. When emitting light, the light is directly emitted from the back of the flat substrate 5; the back surface of the substrate 5 is formed by laser ablation A single cross-sectional shape is a V-shaped plastic concave groove 7 that realizes controllable change of the light output angle through refraction.

[0042] continue as Figure 1 to Figure 3 , the depth of the single shaping recess...

Embodiment 2

[0047] Such as Figure 6 As shown, the difference between this embodiment and the first embodiment is that the cross-sectional shape is a circular arc-shaped plastic concave groove 7, and the shape of the opening of the plastic concave groove 7 on the substrate 5 is also circular, and the shape of the plastic concave groove 7 is circular. The first side wall 71 and the second side wall 72 of the shaping concave groove 7 are arc-shaped; the other structures are similar to those of the first embodiment, and will not be repeated here.

Embodiment 3

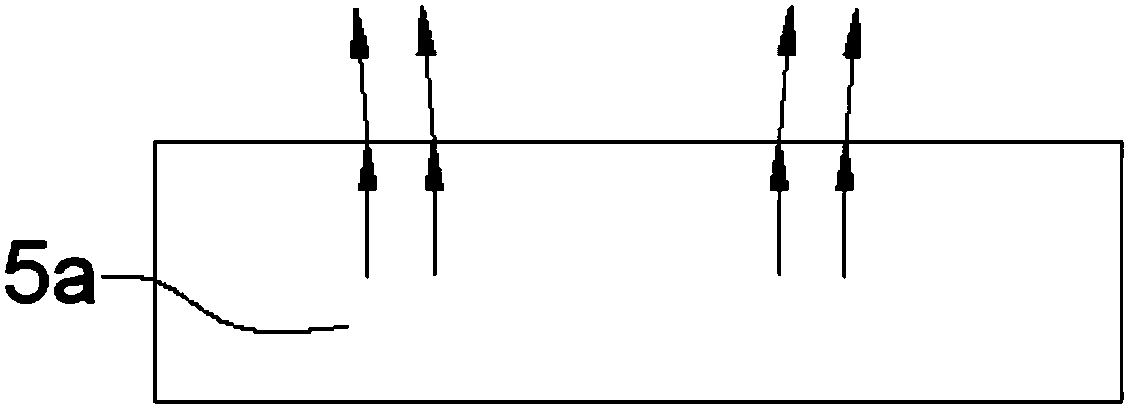

[0049] Such as Figure 7 and Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that laser ablation is used on the back surface of the substrate 5 to form a plurality of plastics with the same size and shape and arranged in an array to realize controllable change of the light output angle through refraction. shaped recessed groove 7, and the cross-sectional shape of each shaped recessed groove 7 on the substrate 5 is V-shaped, a plurality of shaped recessed grooves 7 are arranged continuously, and two adjacent shaped recessed grooves 7 are formed on the substrate The openings on the 5 are connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com