An integrated uranium nitride thermoelectric conversion device

A thermoelectric conversion device, nitride technology, applied in thermoelectric device junction lead-out materials, thermoelectric devices using only Peltier or Seebeck effect, etc., can solve the problems of low conversion efficiency and application requirements, small contact area, etc. The effect of light damage, prolonging service life, reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

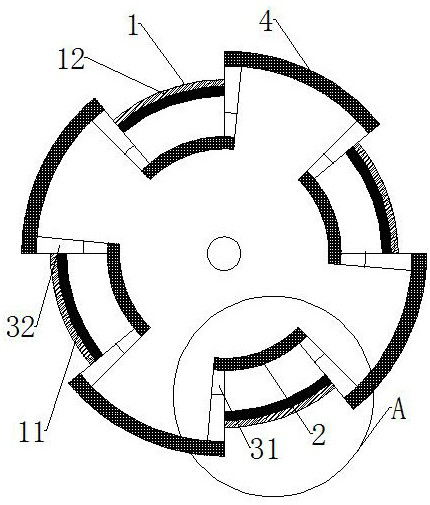

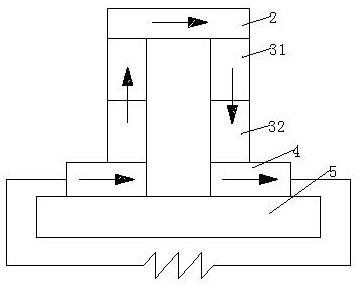

[0029] The present invention is realized through the following technical solutions, as Figure 1-Figure 3 As shown, an integrated uranium nitride thermoelectric conversion device includes a housing 1 and a thermoelectric conversion device installed on the housing 1 and has a self-heating function; the thermoelectric conversion device includes a conversion module; the conversion module includes The first conductive sheet 2, the N-type semiconductor and the P-type semiconductor respectively arranged on both ends of the first conductive sheet 2, and two second conductive sheets 4 respectively connected to the N-type semiconductor and the P-type semiconductor;

[0030] The N-type semiconductor and the P-type semiconductor have the same structure, and are equally divided into a high fission concentration region 31 connected to the first conductive sheet 2 and having a self-heating function, and a low fission concentration region 32 connected to the second conductive sheet 4 .

[00...

Embodiment 2

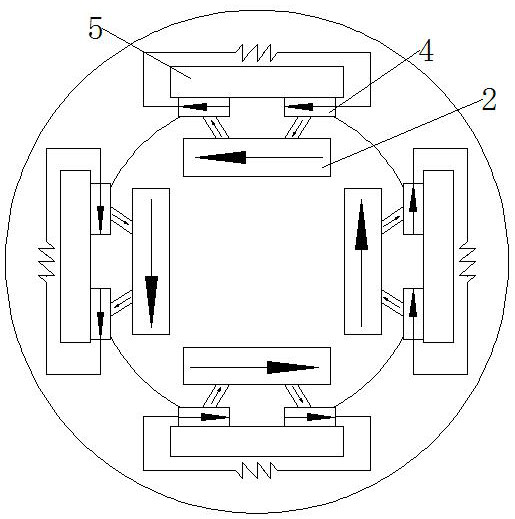

[0039] This embodiment is further optimized on the basis of the above embodiments, such as Figure 1-Figure 3 As shown, further, in order to better realize the present invention, the number of the conversion modules is multiple and ring-connected to form a thermoelectric conversion unit; adjacent conversion modules share a second conductive sheet 4; adjacent conversion modules pass The second conductive sheet 4 is connected, that is, the second conductive sheet 4 is simultaneously connected to the N-type semiconductor of one conversion module and the P-type semiconductor of the other conversion module.

[0040] Further, in order to better realize the present invention, the number of the thermoelectric conversion units is multiple and uniformly distributed along the axial direction of the casing 1 .

[0041] Further, in order to better realize the present invention, the high fission concentration region 31 and the low fission concentration region 32 are made of uranium nitride ...

Embodiment 3

[0047] This embodiment is the best embodiment of the present invention, as Figure 1-Figure 3 As shown, an integrated uranium nitride thermoelectric conversion device includes a housing 1 and a thermoelectric conversion device installed on the housing 1 and has a self-heating function; the thermoelectric conversion device includes a conversion module; the conversion module includes The first conductive sheet 2, the N-type semiconductor and the P-type semiconductor respectively arranged on both ends of the first conductive sheet 2, and two second conductive sheets 4 respectively connected to the N-type semiconductor and the P-type semiconductor;

[0048] The N-type semiconductor and the P-type semiconductor have the same structure, and are equally divided into a high fission concentration region 31 connected to the first conductive sheet 2 and having a self-heating function, and a low fission concentration region 32 connected to the second conductive sheet 4 .

[0049] The numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com