A terminal crimping device and a terminal crimping method

A terminal crimping and terminal technology, applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the problems of poor appearance of core wire and plastic wire crimping, affecting terminal contact resistance, cold pressing quality defect, etc. It can achieve the effect of good pressing and limiting effect, improving the precision of pressing and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

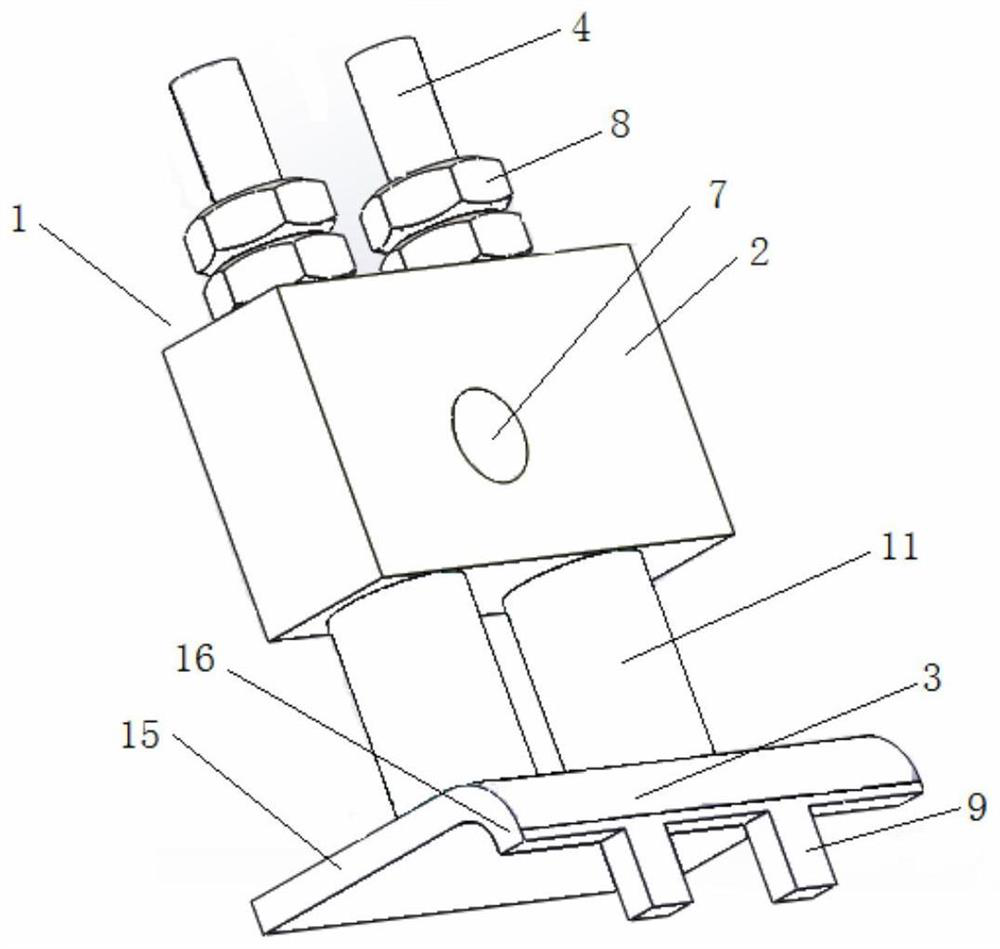

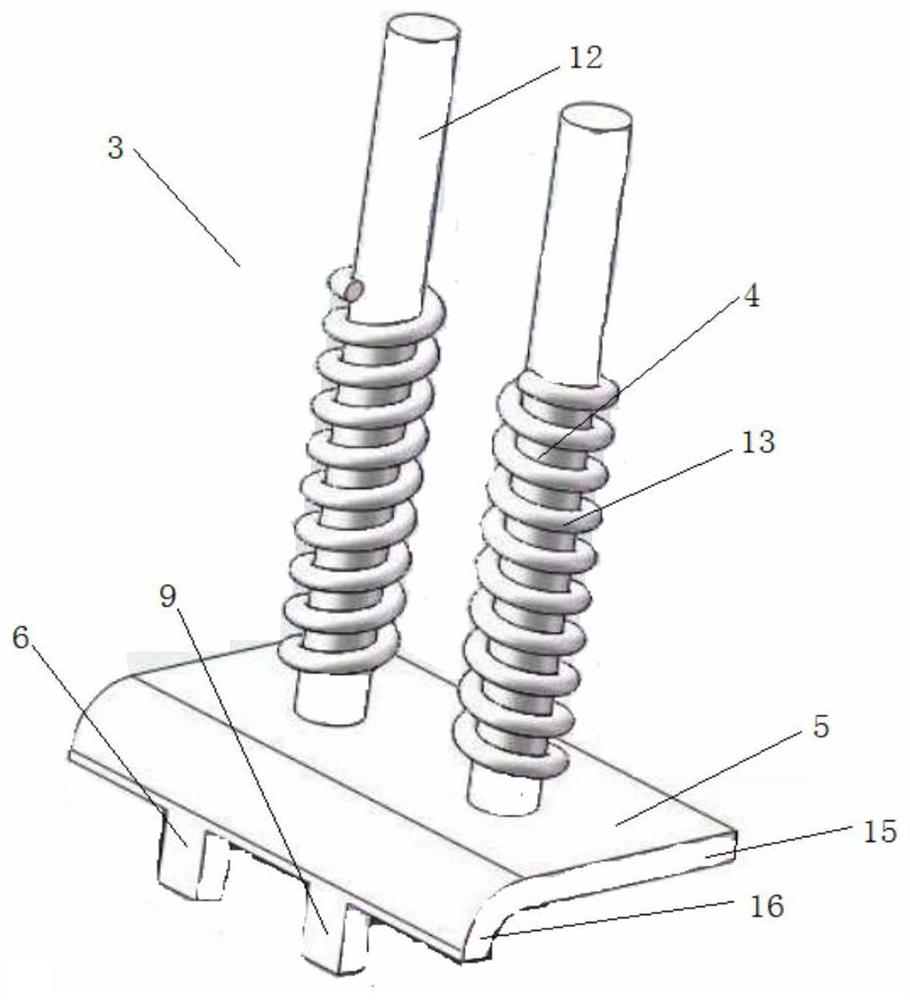

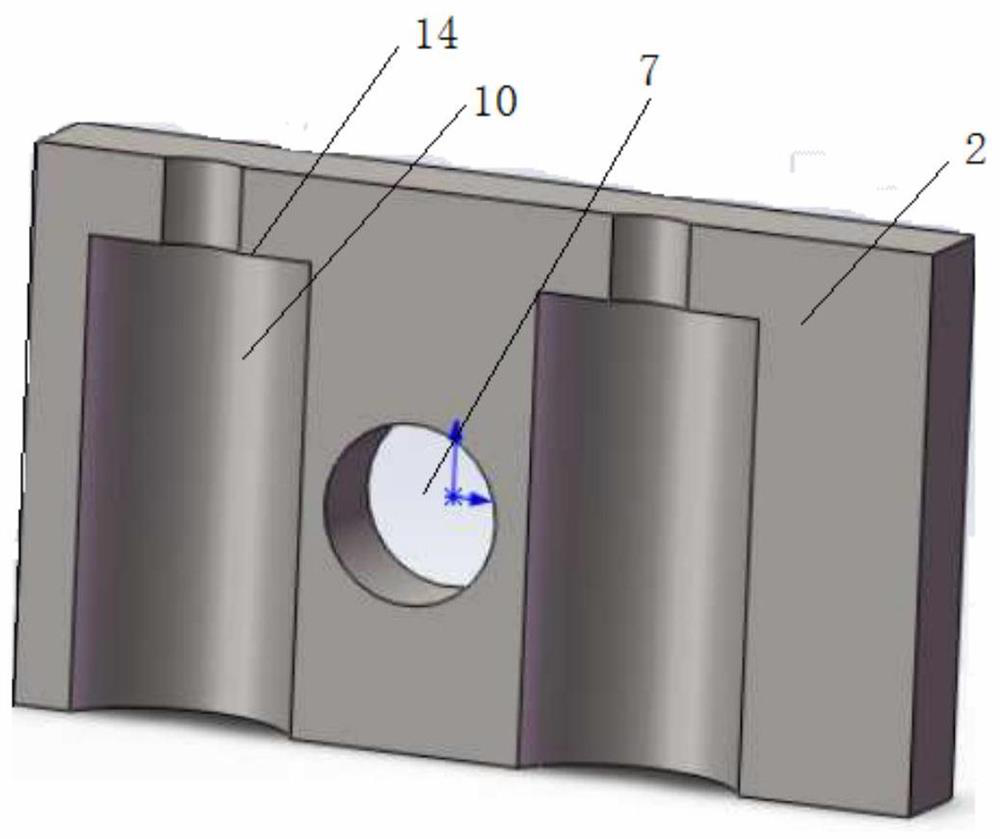

[0028] The present invention provides a terminal crimping device, including a crimping pliers, the crimping pliers including an upper mold and a lower mold capable of fixing a terminal insert and a cable respectively, and a cable positioning device 1 is fixed on the crimping pliers.

[0029] In the embodiment provided by the present invention, the existing crimping tool is mainly improved by adding a cable positioning device to realize a terminal crimping device capable of positioning the cable. In this embodiment, the crimping tool can adopt the prior art For example, take the crimping tool used in the crimping process of the F-type crimping film crimping open terminal as an example. Other types of crimping tools can be adapted according to the specific structure, such as HARTING 09990000620 type crimping tools. The pressure clamp structure is the pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com