Steel tubing placement rack of machinery plant

A technology for machinery factories and racks, applied in the field of steel pipes, can solve the problems of easy entry of impurities in steel pipes, troublesome protection work, affecting the use of steel pipes, etc., and achieve the effects of convenient protection work, guaranteeing cleanliness and guaranteeing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

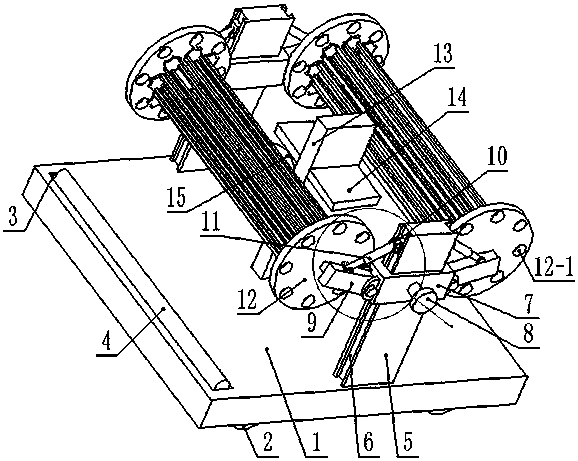

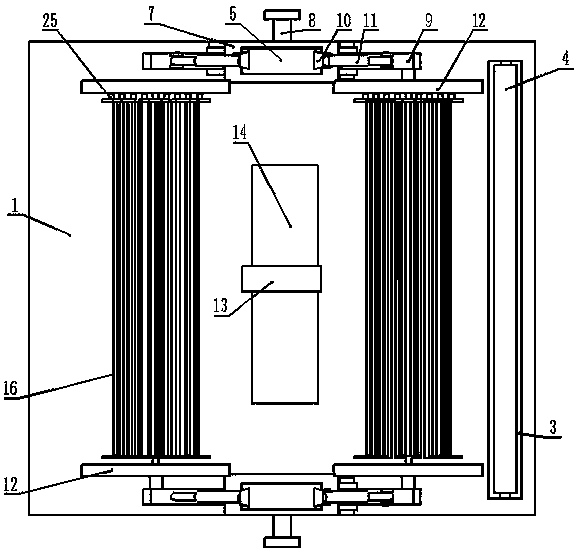

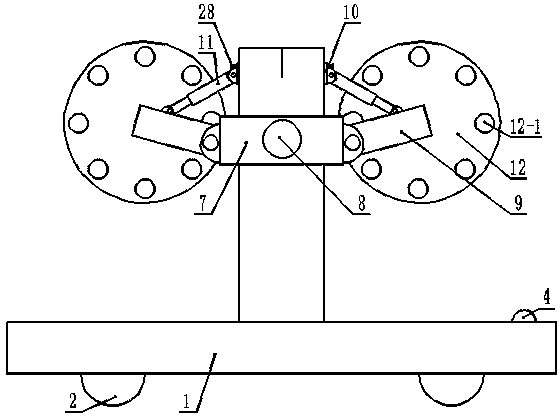

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] Such as Figure 1-Figure 8 As shown, a steel pipe placement frame in a machinery factory includes a base 1 and a rotating placement bracket. The rotating placement bracket includes a corresponding pair of rotating disks 12, and the rotating disks 12 are evenly provided with a number of insertion holes 12 in a circular shape. -1, between the corresponding pair of said rotating discs 12, there are several placing racks which are uniformly supported and rotated in a ring.

[0029] Preferably, the placement frame 16 includes corresponding side plates A17 and side plates B18, the side plate A17 is provided with a through hole 17-1, and a fan 27 for blowing is arranged in the through hole 17-1, One side of the side plate A17 is provided with a motor 25, and the motor 25 is fixed to the side plate A17 through a curved fixing rod 26. The shaft o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com