Intelligent timber processing equipment

A technology of processing equipment and wood, applied in the field of intelligent wood processing equipment, can solve problems such as low work efficiency and long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

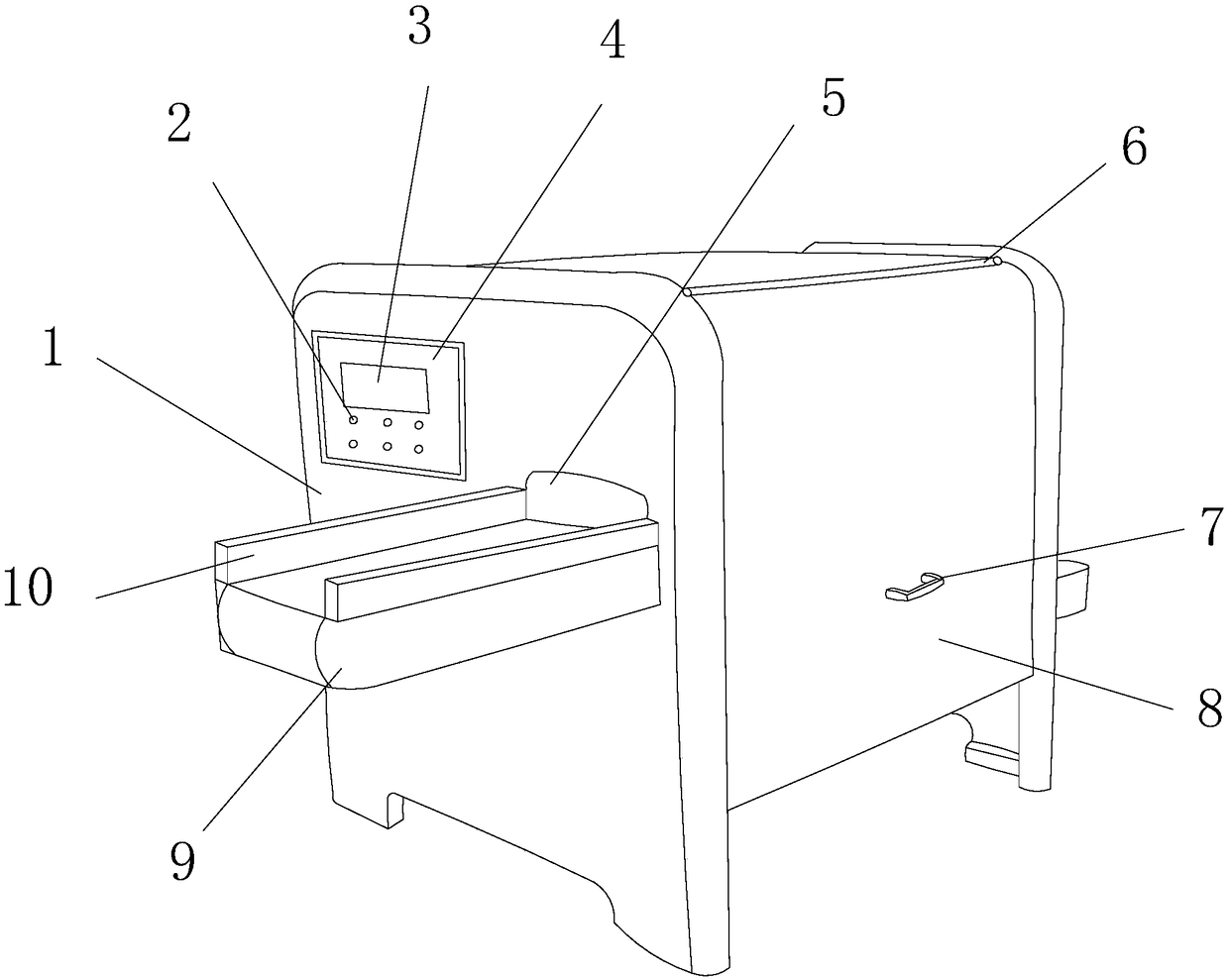

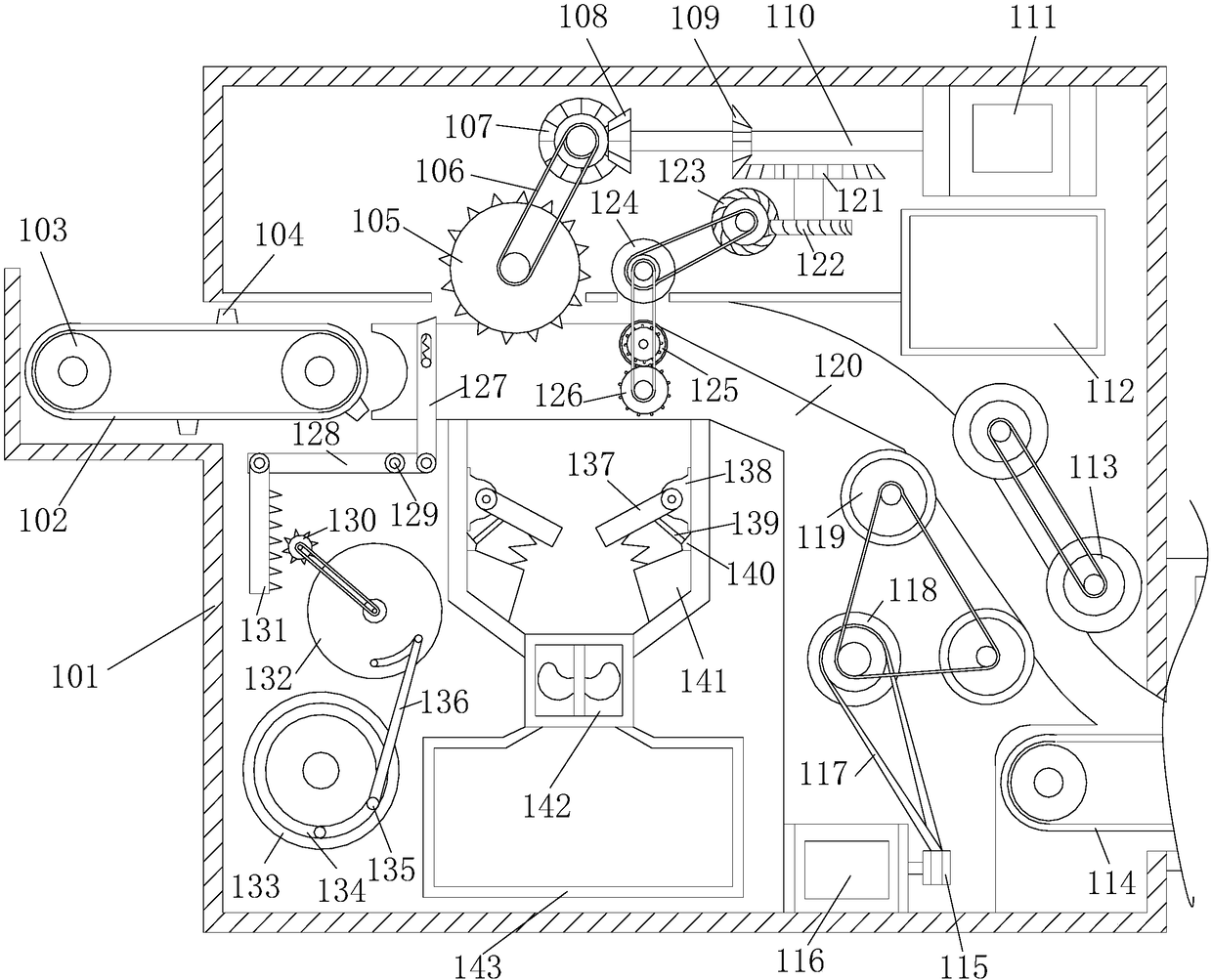

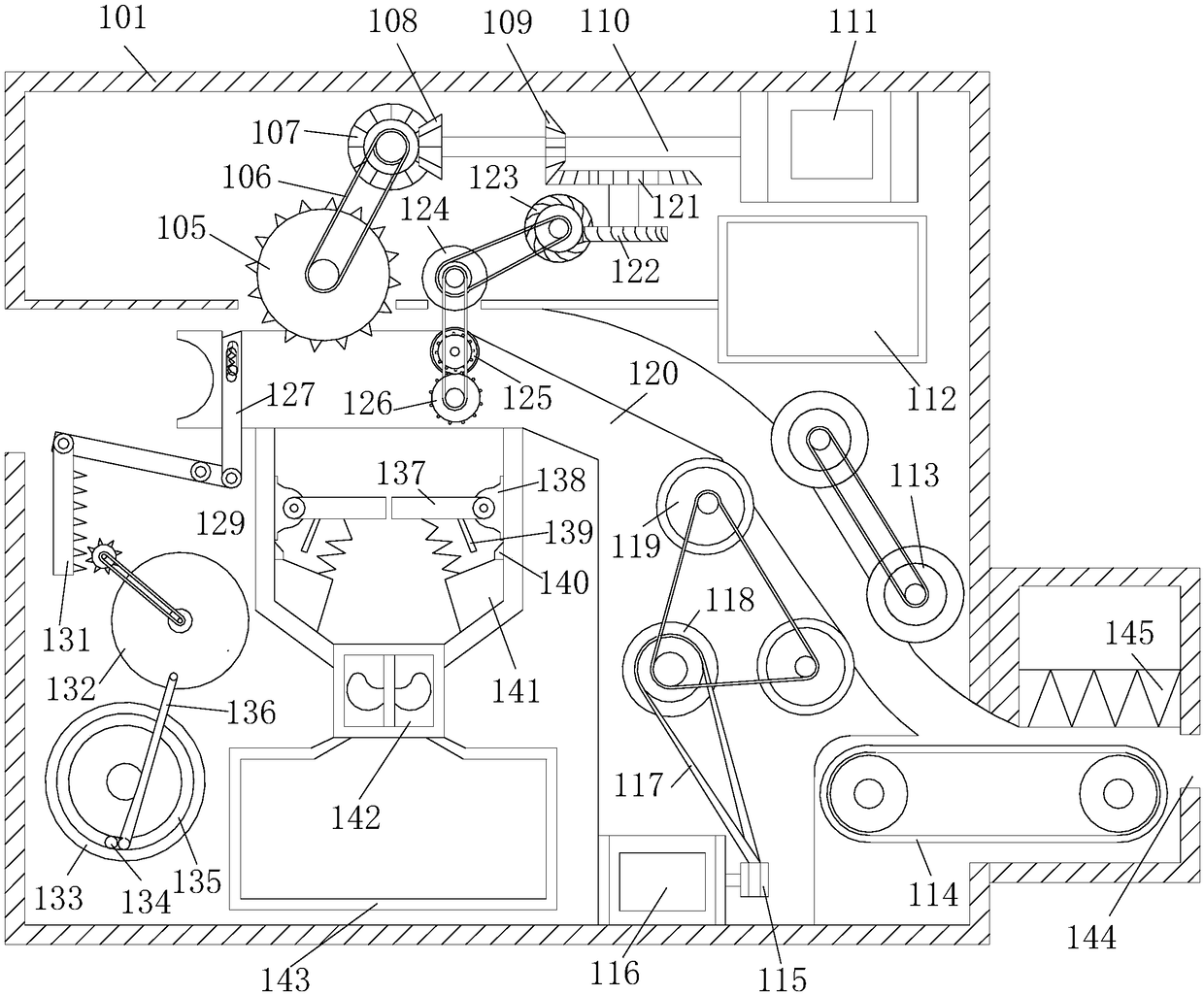

[0023] see Figure 1-Figure 5 , the present invention provides a technical scheme of intelligent wood processing equipment: its structure includes wood processing equipment 1, control buttons 2, display 3, control panel 4, wood entrance 5, hinged rod 6, handle 7, side plate 8, wood entrance platform 9. Fence board 10, the left end surface of the wood processing equipment 1 is connected with the right end of the wood entrance platform 9 and the two are perpendicular to each other, the upper right end of the wood entrance platform 9 is the wood entrance 5, and the upper right end of the wood processing equipment 1 The end face is provided with a fence board 10 and the two are perpendicular to each other. The fence board 10 has two pieces and is para...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap