PC (polycarbonate)/ABS (acrylonitrile butadiene styrene) composition with excellent heat conductivity and preparation method thereof

A technology of composition and thermal conductivity, which is applied in the field of PC/ABS composition with excellent thermal conductivity and its preparation, can solve the problems of a large number of thermal conductive fillers and low thermal conductivity, and achieve high thermal conductivity and improved thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

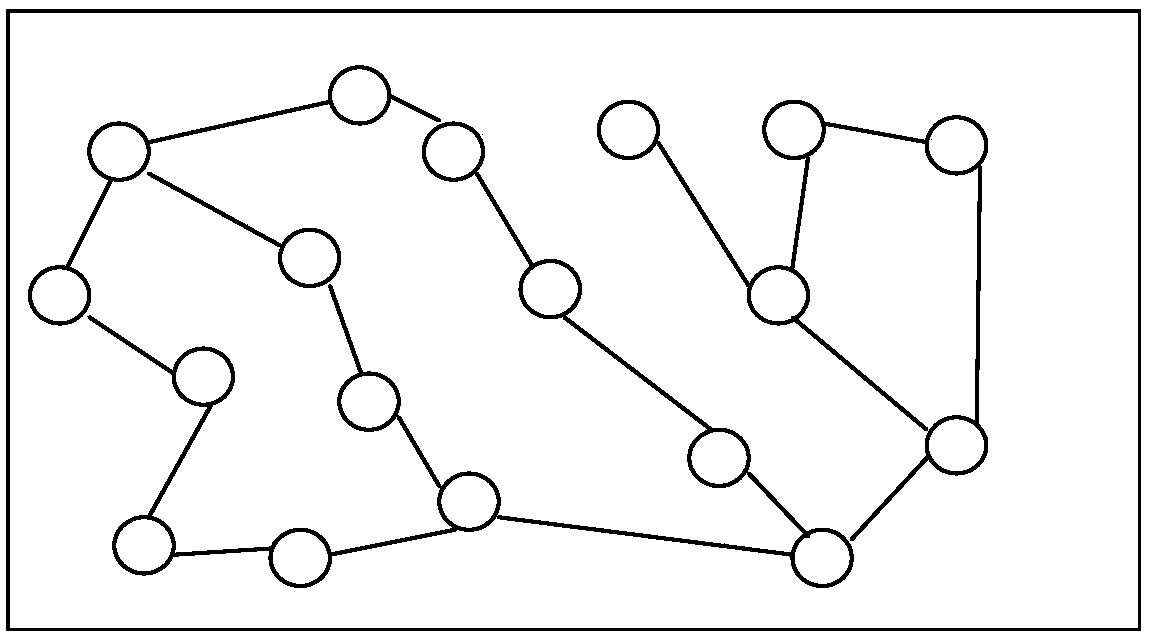

Image

Examples

Embodiment 1

[0033] A kind of preparation method of PC / ABS composition with excellent thermal conductivity, adopts the following steps:

[0034] (1) Weigh each component by weight: PC is PC-1220: 60, ABS8434: 30, boron nitride: 8, CNT: 2, antioxidant 1010 0.1, antioxidant 168 0.1, lubricant PETS 0.3 .

[0035] (2) Boron nitride and CNT are pre-mixed and then mixed with other raw materials evenly, then fed from the feeding port of the extruder, and melted and extruded at 220-260 °C, the screw extruder speed is 500rpm, and the pressure is 2MPa , after melt extrusion and granulation, the product can be obtained.

Embodiment 2

[0037] A kind of preparation method of PC / ABS composition with excellent thermal conductivity, adopts the following steps:

[0038] (1) Weigh each component by weight: PC is L1250Y: 80, ABS8434: 10, CNT: 2, boron nitride: 8, antioxidant 1010 0.1, antioxidant 168 0.1, lubricant PETS 0.3.

[0039] (2) Boron nitride and CNT are pre-mixed with other raw materials and fed from the extruder, melted and extruded at 220-260 °C, the screw extruder speed is 500rpm, the pressure is 2MPa, after Melt extrusion and granulation to get the product.

Embodiment 3

[0041] A kind of preparation method of PC / ABS composition with excellent thermal conductivity, adopts the following steps:

[0042] (1) Weigh each component by weight: PC is PC-1220: 70, ABS8434: 30, boron nitride: 8, CNT: 2, antioxidant 1010 0.1, antioxidant 168 0.1, lubricant PETS 0.3 .

[0043] (2) Boron nitride and CNT are pre-mixed with other raw materials and fed from the extruder, melted and extruded at 220-260 °C, the screw extruder speed is 500rpm, the pressure is 2MPa, after Melt extrusion and granulation to get the product

[0044] Each comparative example and embodiment was injection-molded into a flat plate of 100*80*3mm, and tested by a DRL-3 thermal conductivity tester of Xiangke, the results are as follows:

[0045]

[0046] It can be seen from the table that when no thermal conductive filler is added, the thermal conductivity of PC / ABS is about 0.2W / mk (both PC and ABS are 0.2-0.25). When 10 parts of cubic boron nitride is added to PC / ABS, the mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com