Device and process for cyclically absorbing and producing balm

A technology of balsam and absorption tower, which is applied in the field of balsam production through circular absorption, which can solve the problems of affecting the comprehensive utilization of dried flowers, small oil surface area, and low production efficiency, and achieves easy realization of large-scale production, increased contact absorption area, and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

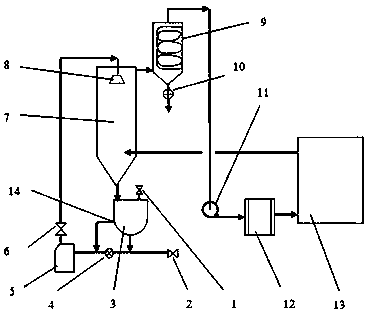

[0026] Embodiment 1: as figure 1 As shown, the device for absorbing and producing balsam in this cycle specifically includes a feeding valve 1, a discharging valve 2, a constant temperature storage tank 3, a ball valve 4, a high-pressure pump 5, a pressure regulating valve 6, an absorption tower 7, a high-pressure nozzle 8, and a coil cooler 9. Automatic drain valve 10, circulation fan 11, air heater 12, drying room 13;

[0027] The top of the constant temperature storage tank 3 is provided with a feeding valve 1, the side outlet 14 of the constant temperature storage tank 3 communicates with the high pressure pump 5 through a pipeline, the outlet of the high pressure pump 5 communicates with the high pressure nozzle 8 through a pipeline, and the outlet pipeline of the high pressure pump 5 is provided with a regulating valve. The pressure valve 6 and the high-pressure nozzle 8 are installed inside the top of the absorption tower 7. The upper part of the absorption tower 7 comm...

Embodiment 2

[0034] Embodiment 2: present embodiment device structure is the same as embodiment 1, and this circulation absorbs the technique of the device producing balsam, and concrete steps are as follows:

[0035] (1) Close the discharge valve 2, add the grease for absorption from the feed valve 1 to the constant temperature storage tank 3, close the feed valve 1 after adding, heat the grease in the constant temperature storage tank 3 to 40°C, close the ball valve 4, Start the high-pressure pump 5. Grease is sucked out by the high-pressure pump 5 and delivered to the high-pressure nozzle in the absorption tower through the pipeline. The pressure regulating valve 6 above the high-pressure pump 5 adjusts the atomization pressure of the grease to 0.8MPa. The high-pressure nozzle 8 atomizes the grease into fine particles. Droplets, which fall downwards under the force of gravity;

[0036] (2) Pack fresh fragrant flowers into stainless steel grid trays, and then place them on the shelves in...

Embodiment 3

[0038] Embodiment 3: the device structure of this embodiment is the same as embodiment 1, and this circulation absorbs the technique of the device producing balsam, and concrete steps are as follows:

[0039] (1) Close the discharge valve 2, add the grease for absorption from the feed valve 1 to the constant temperature storage tank 3, close the feed valve 1 after adding, heat the grease in the constant temperature storage tank 3 to 45°C, close the ball valve 4, Start the high-pressure pump 5. Grease is sucked out by the high-pressure pump 5 and delivered to the high-pressure nozzle in the absorption tower through the pipeline. The pressure regulating valve 6 above the high-pressure pump 5 adjusts the atomization pressure of the grease to 1.2 MPa, and the high-pressure nozzle 8 atomizes the grease into fine particles. Droplets, which fall downwards under the force of gravity;

[0040] (2) Pack fresh fragrant flowers into stainless steel grid trays, and then place them on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com