Plug for automobile fuel pump

A fuel pump and plug technology, which is applied to liquid fuel feeders, engine components, machines/engines, etc., can solve problems such as poor isolation effect, and achieve comprehensive protection and tight coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

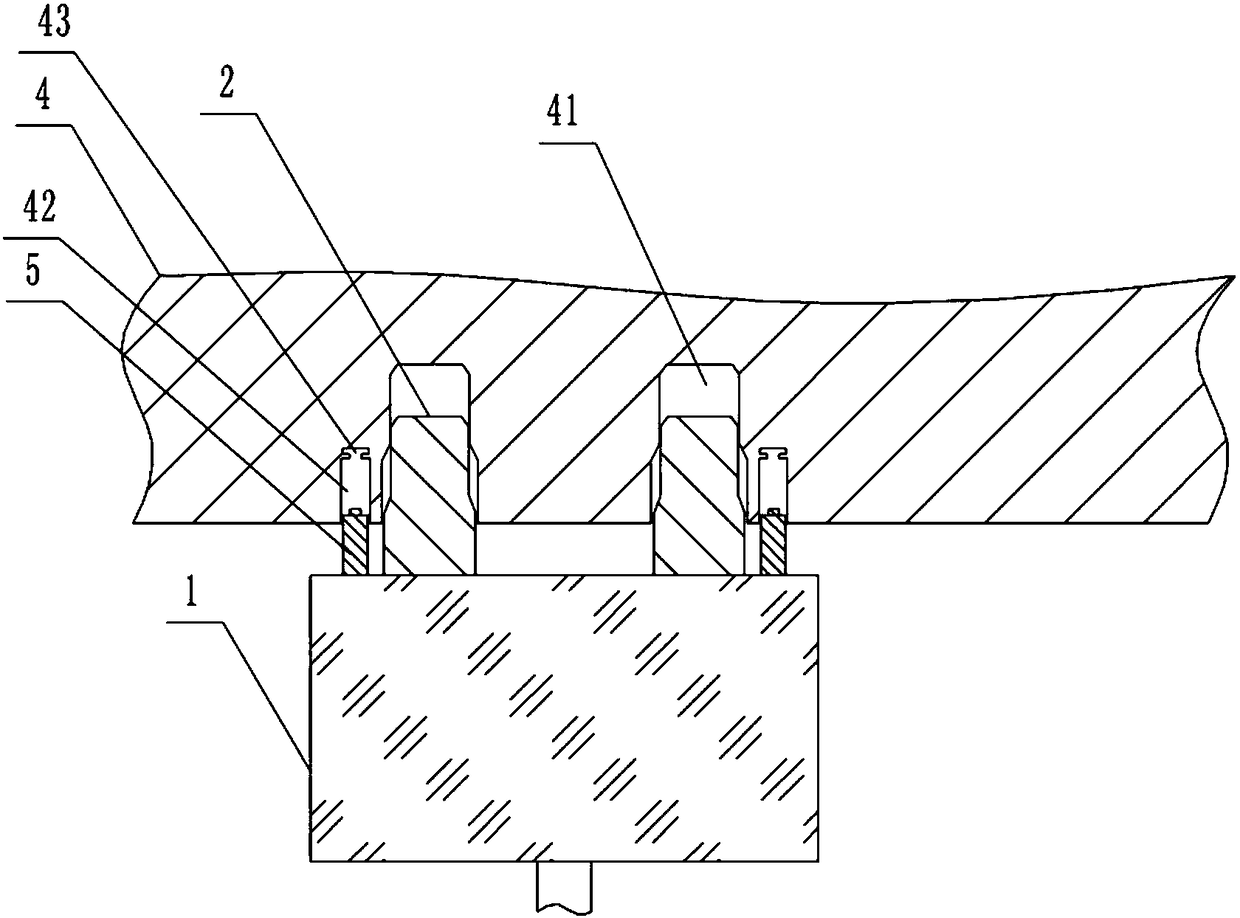

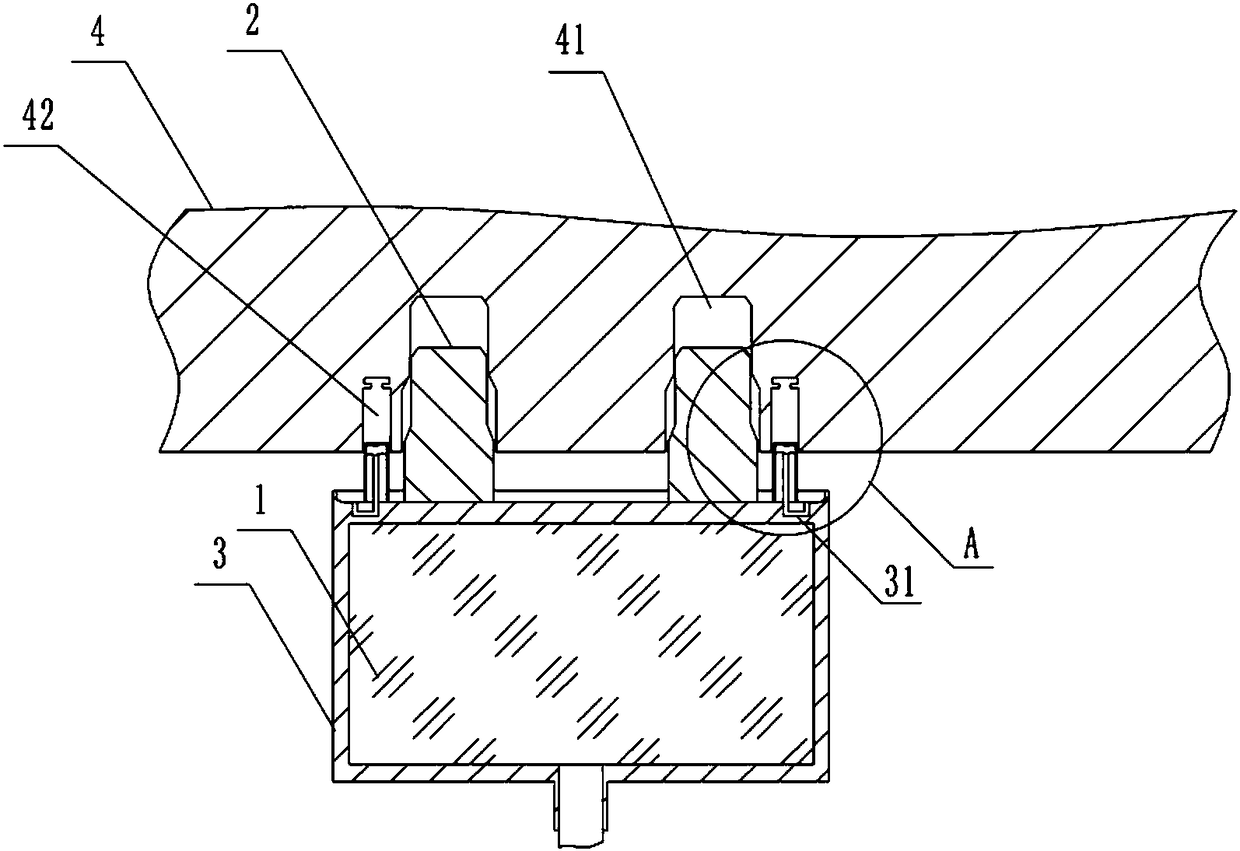

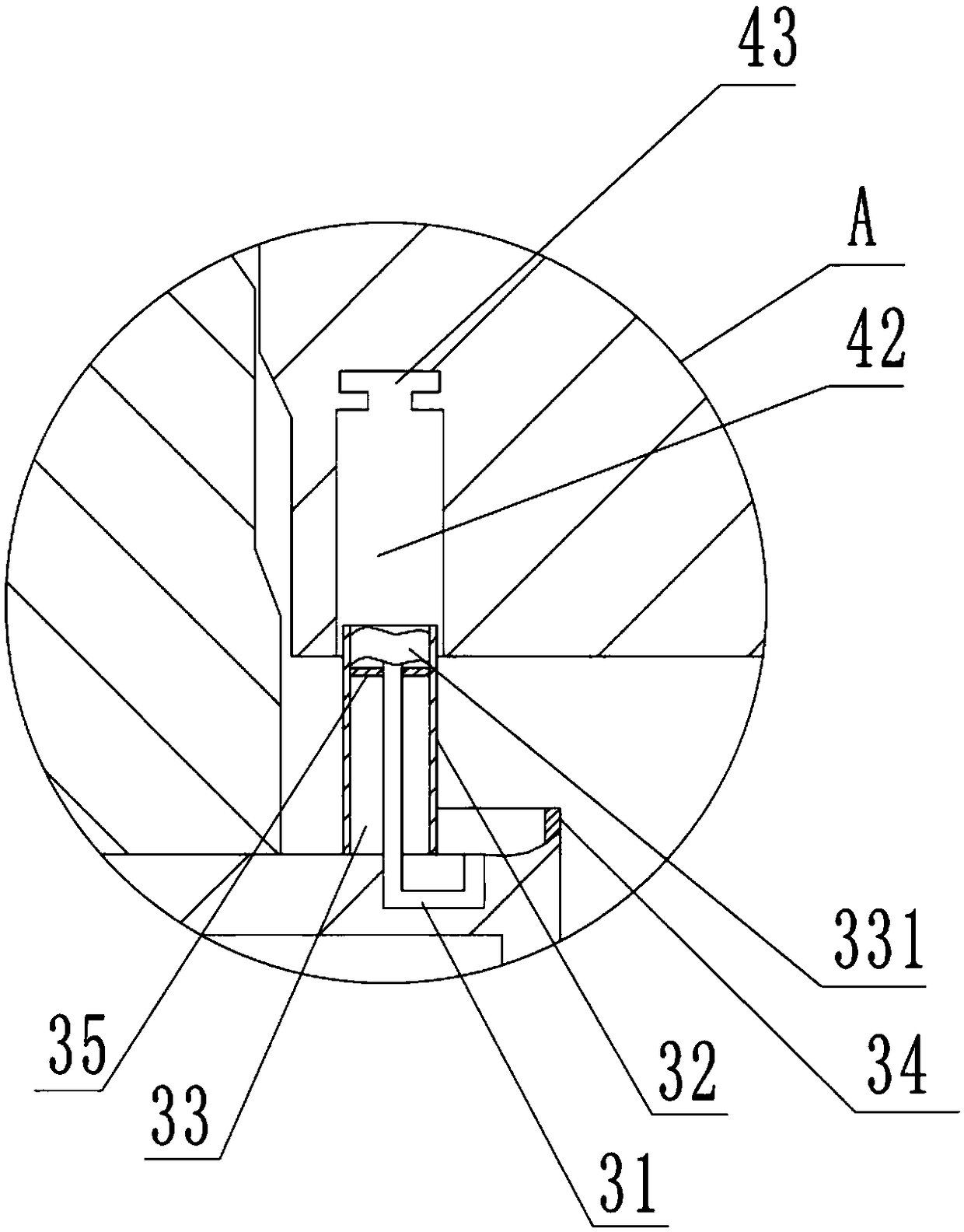

[0025] A plug for an automobile fuel pump, including a plug body 1 and pins 2 located on the plug body 1; also includes an anti-corrosion layer 3 wrapped on the outer surface of the plug body 1, and the pins 2 pass through the anti-corrosion layer 3; anti-corrosion A fuel pipe 31 for fuel oil entry is provided in the layer; an isolating ring 32 is fixed on the anti-corrosion layer 3, and the isolating ring 32 is located in the circumferential direction of the pin 2; an annular groove 33 is arranged in the isolating ring 32; There is a circle of annular air bag 331, and the annular air bag 331 communicates with the fuel pipe 31;

[0026] A rubber ring 34 is also fixed on the edge of the upper surface of the anti-corrosion layer 3 , and the inlet of the fuel pipe 31 is located between the rubber ring 34 and the spacer ring 32 .

[0027] The surface between the rubber ring 34 and the inlet of the fuel pipe 31 is a slope inclined downward toward the inlet of the fuel pipe 31 . Th...

Embodiment 2

[0031] The difference between this embodiment and embodiment 1 is that the anti-corrosion layer 3 is a titanium alloy layer.

[0032] When in use, the pin 2 is inserted into the socket hole 41 ; the isolation ring 32 is inserted into the annular groove 42 . The rubber ring 34 bears against the surface of the socket 4 . Fuel oil can be stopped by rubber ring 34 earlier, can not contact with pin 2. When the rubber ring 34 is damaged, the fuel will enter the fuel pipe 31 and enter the airbag through the fuel pipe 31. After the airbag gradually expands, it will be in close contact with the inner bottom surface of the annular groove 42, thereby preventing the fuel from entering the isolation ring. 32 and the contact surface of the annular groove 42. In addition, if the airbag continues to expand, it will enter the fixing groove 43 on the inner bottom of the annular groove 42; since the cross section of the fixing groove 43 is T-shaped, the airbag will snap into the fixing groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com