Closed spray cooling experiment system suitable for various cooling madia

An experimental system, spray cooling technology, applied in the direction of measuring devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

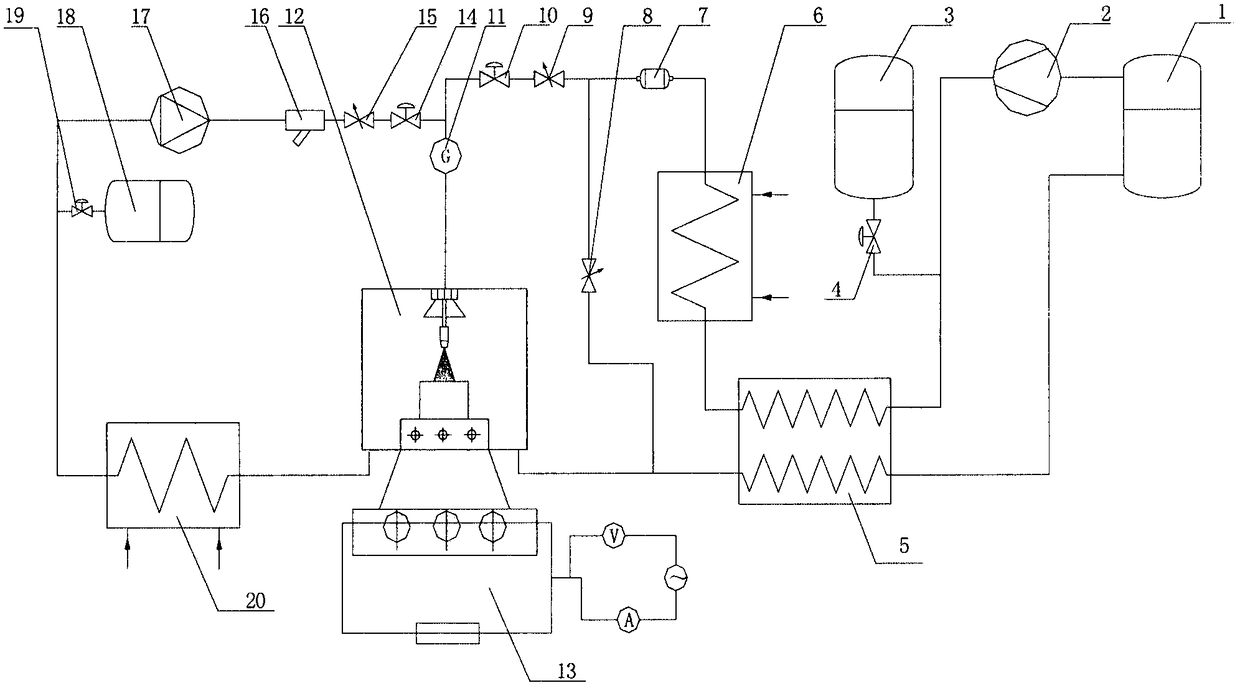

[0024] Such as figure 1 As shown, a closed spray cooling experimental system suitable for various cooling media mainly includes a gas-liquid separator 1, a compressor 2, a refrigerant storage tank 3, a first stop valve 4, a precooler 5, and a refrigerant Condenser 6, dry filter 7, bypass regulating valve 8, first flow regulating valve 9, second stop valve 10, flow meter 11, spray chamber 12, auxiliary electric heater 13, third stop valve 14, second A flow regulating valve 15 , a filter 16 , a pump 17 , a non-refrigerant liquid storage tank 18 , a fourth stop valve 19 , and a non-refrigerant condenser 20 .

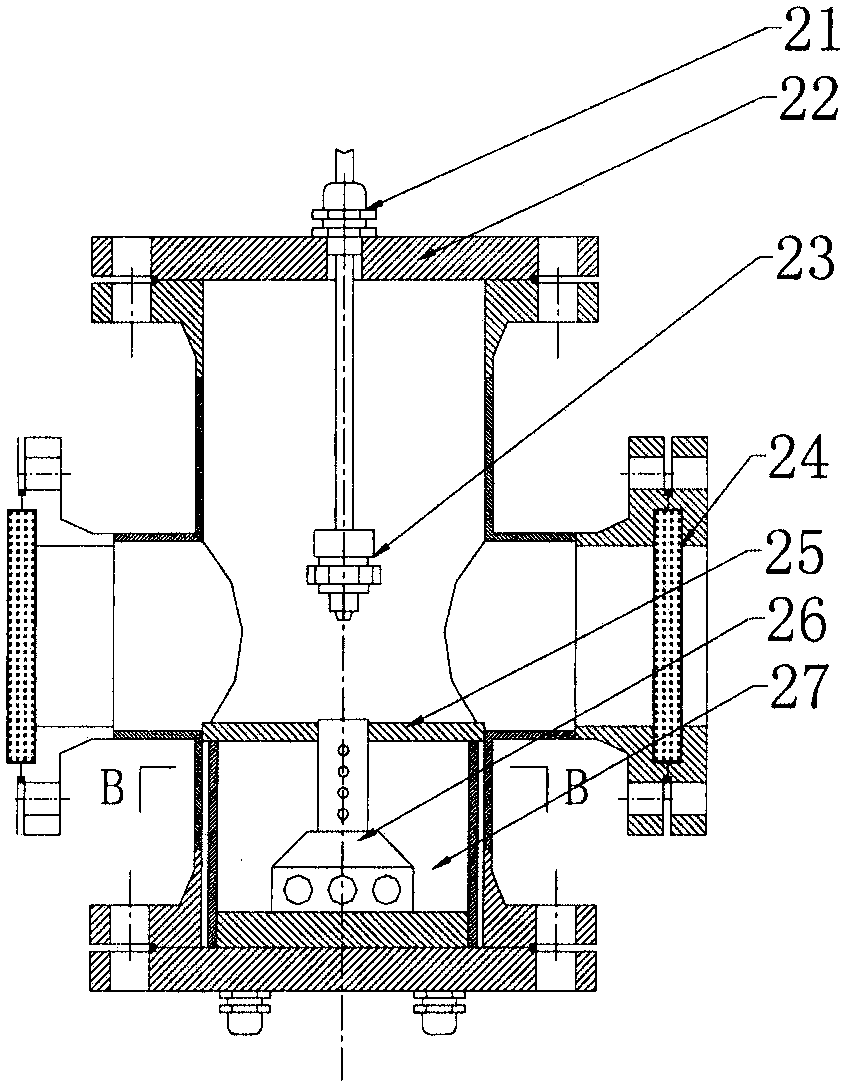

[0025] The composition of spray chamber 12 is as figure 2 As shown, it mainly includes a height adjustment nut 21, a pressure-resistant casing 22, a nozzle 23, an observation window 24, a bakelite board 25, a heating block 26, and an insulation layer 27.

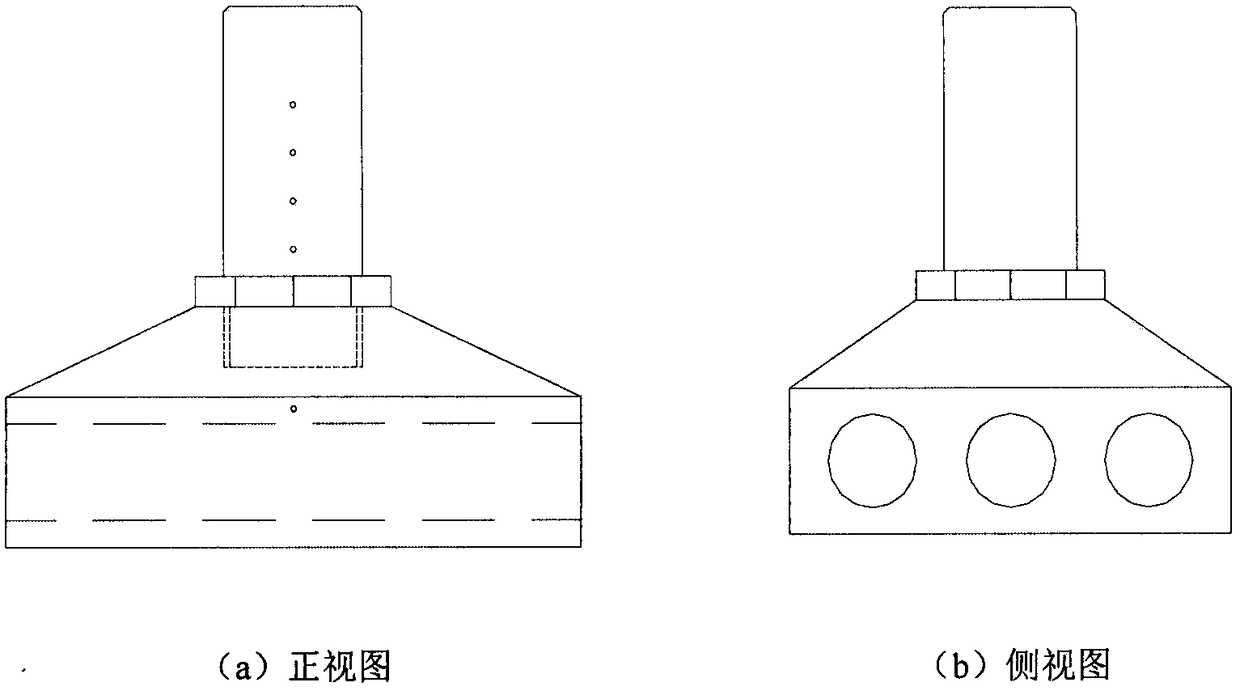

[0026] The shape of heating block 26 is as image 3 As shown, the heating block is a split structure, wherein the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com