Industrial coupling agent for detection of steel rails and preparation method thereof

A couplant, an industrial technology, applied in the field of rail flaw detection industrial couplant and its preparation, can solve the problems of poor sound transmission effect, difficult penetration of ultrasonic waves into the workpiece, and influence on accurate detection of rail conditions, etc., to achieve excellent sound transmission effect and wide Application prospects, the effect of excellent anti-rust and anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

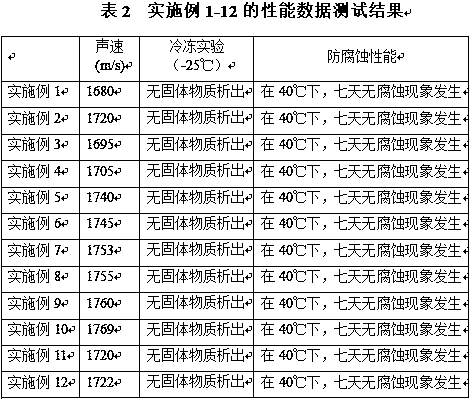

Examples

Embodiment 1-4

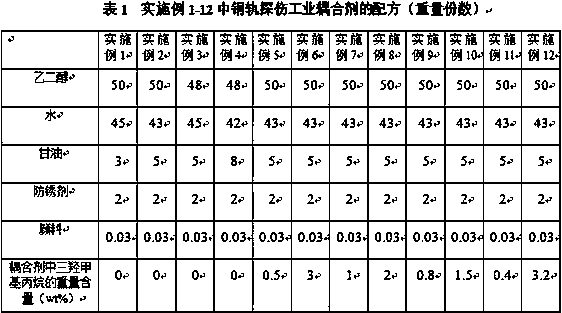

[0028] The preparation of embodiment 1-4 rail flaw detection industry couplant:

[0029] According to the formula in Table 1, take water and add it to the reaction kettle, then add ethylene glycol while stirring, and continue to stir for 15 minutes after the ethylene glycol is completely dissolved; add glycerin and antirust agent to the reaction kettle in turn, stir and mix evenly; Add it into the reaction kettle and stir for 30 minutes to obtain the rail flaw detection industrial couplant.

Embodiment 5-12

[0030] Embodiment 5-12 Preparation of rail flaw detection industry couplant:

[0031] According to the formula in Table 1, take water and add it to the reaction kettle, then add ethylene glycol while stirring, and continue stirring for 15 minutes after the ethylene glycol is completely dissolved; add trimethylolpropane, glycerin, and antirust agent into the reaction kettle in turn, Stir and mix evenly; add the pigment to the reaction kettle, and stir for 30 minutes to obtain the rail flaw detection industrial couplant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com