Fluorosilane modified polyether type polyurethane underwater sound transmission material and preparation method thereof

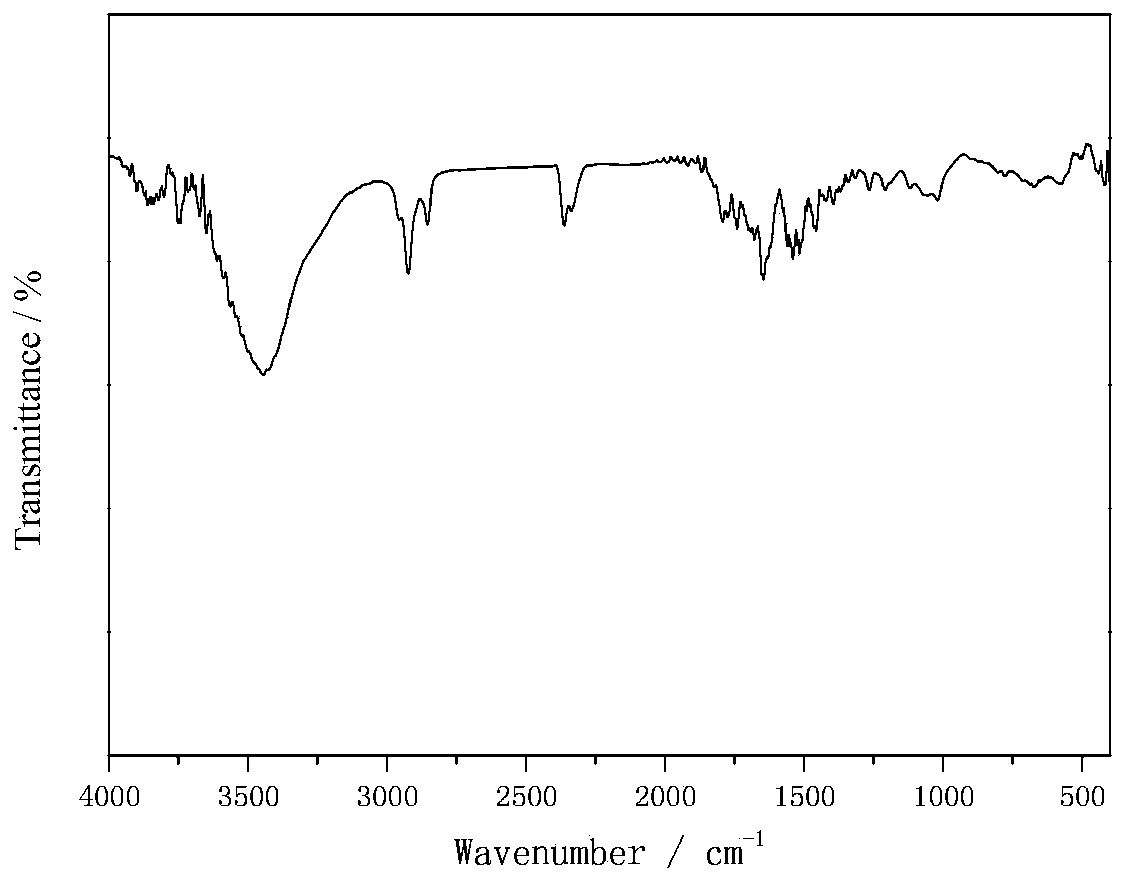

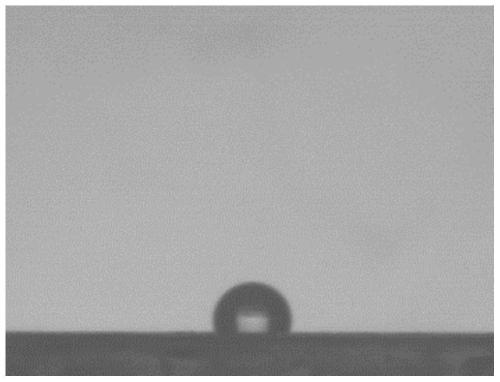

A technology of polyether polyurethane and sound-transmitting material is applied in the field of hydroacoustic materials, which can solve the problems of poor water resistance and water tightness, low comprehensive mechanical properties, low water resistance and surface tension, etc., and achieve hydrophobicity. The effect of improved performance, good chemical stability and strong hydrophobicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]1) Add 150g of polytetrahydrofuran diol, 0.096g of perfluorodecyltrimethoxysilane and 9.484g of polytrifluoropropylmethylsiloxane into a three-necked flask equipped with a stirrer and a thermometer, and raise the temperature to 105°C. Dehydrate under vacuum for 1 hour until the tested moisture content is lower than 0.05%, then cool to 40-50°C, add 1 drop of catalyst, slowly add 31.92g of toluene diisocyanate, and slowly heat the system to (80±5)°C after naturally heating up , and the prepolymer was obtained after the insulation reaction.

[0029] 2) After adding 45.48g of reactive diluent, stir for 40min, vacuum defoam for 10min, add 19.70g of chain extender, stir quickly, pour into the mold coated with release agent after vacuum defoaming for 2min, and vulcanize at room temperature for one week.

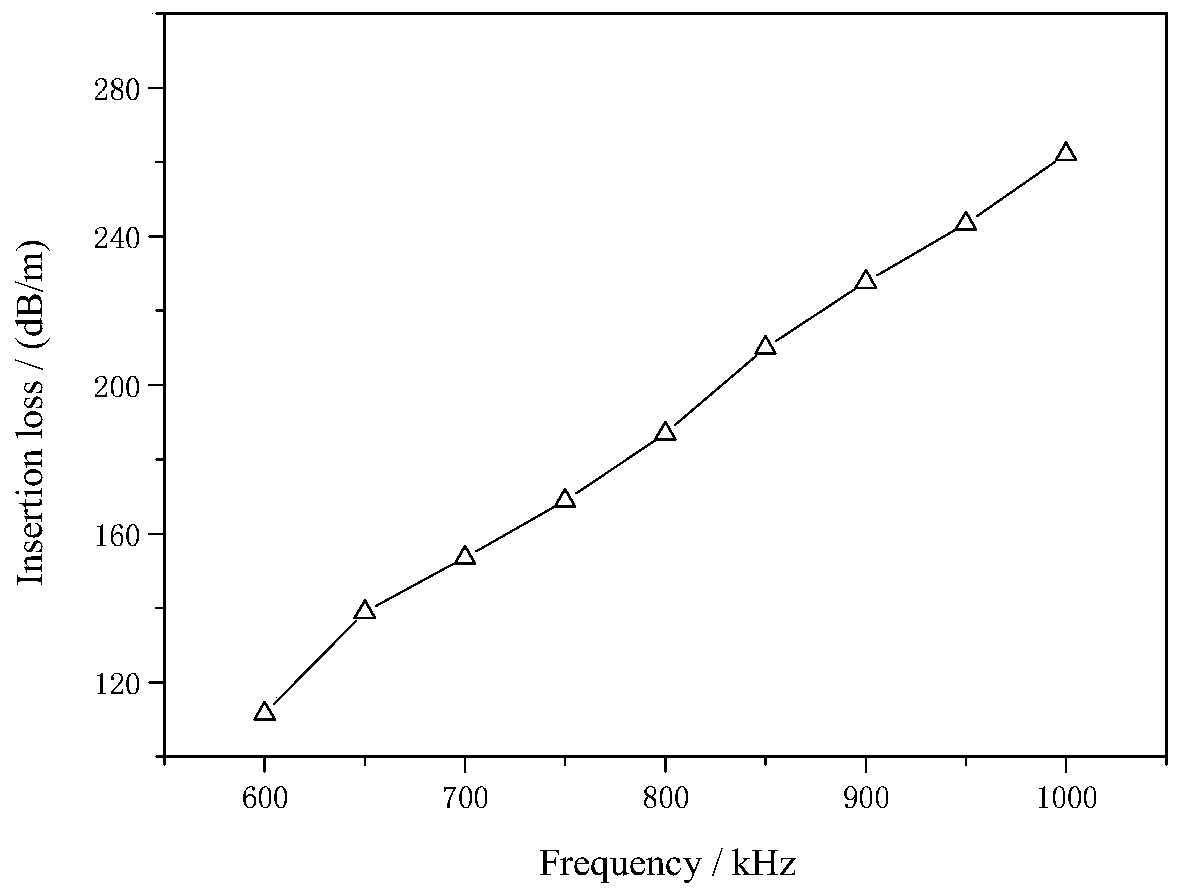

[0030] The resulting fluorosilicone modified polyether polyurethane has a density of 1089kg / m 3 , the characteristic acoustic impedance is 1.682×10 5 g / (cm 2 ·s), the glass...

Embodiment 2

[0032] 1) Add 150g of polytetrahydrofuran diol, 0.287g of perfluorodecyltrimethoxysilane and 9.293g of polytrifluoropropylmethylsiloxane into a three-necked flask equipped with a stirrer and a thermometer, and raise the temperature to 105°C. Dehydrate under vacuum for 1 hour until the tested moisture content is lower than 0.05%, then cool to 40-50°C, add 1 drop of catalyst, slowly add 31.92g of toluene diisocyanate, and slowly heat the system to (80±5)°C after naturally heating up , and the prepolymer was obtained after the insulation reaction.

[0033] 2) After adding 45.48g of reactive diluent, stir for 40min, vacuum defoam for 10min, add 19.70g of chain extender, stir quickly, pour into the mold coated with release agent after vacuum defoaming for 2min, and vulcanize at room temperature for one week.

[0034] The resulting fluorosilane-modified polyether polyurethane has a density of 1080kg / m 3 , the characteristic acoustic impedance is 1.663×10 5 g / (cm 2 ·s), the glass ...

Embodiment 3

[0036] 1) Add 150g of polytetrahydrofuran diol, 0.479g of perfluorodecyltrimethoxysilane and 9.101g of polytrifluoropropylmethylsiloxane into a three-necked flask equipped with a stirrer and a thermometer, and raise the temperature to 105°C. Dehydrate under vacuum for 1 hour until the tested moisture content is lower than 0.05%, then cool to 40-50°C, add 1 drop of catalyst, slowly add 31.92g of toluene diisocyanate, and slowly heat the system to (80±5)°C after naturally heating up , and the prepolymer was obtained after the insulation reaction.

[0037] 2) After adding 45.48g of reactive diluent, stir for 40min, vacuum defoam for 10min, add 19.70g of chain extender, stir quickly, pour into the mold coated with release agent after vacuum defoaming for 2min, and vulcanize at room temperature for one week.

[0038] The resulting fluorosilane-modified polyether polyurethane has a density of 1085kg / m 3 , the characteristic acoustic impedance is 1.666×10 5 g / (cm 2 s), the glass t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com