Waste machine tool remanufacturing innovative design method based on TRIZ and expandable diverging tree

A technology of innovative design and remanufacturing, applied in the field of innovative design of waste machine tool remanufacturing, can solve the problems of confusion, lack of design ideas, and restricting the innovation principle of TRIZ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

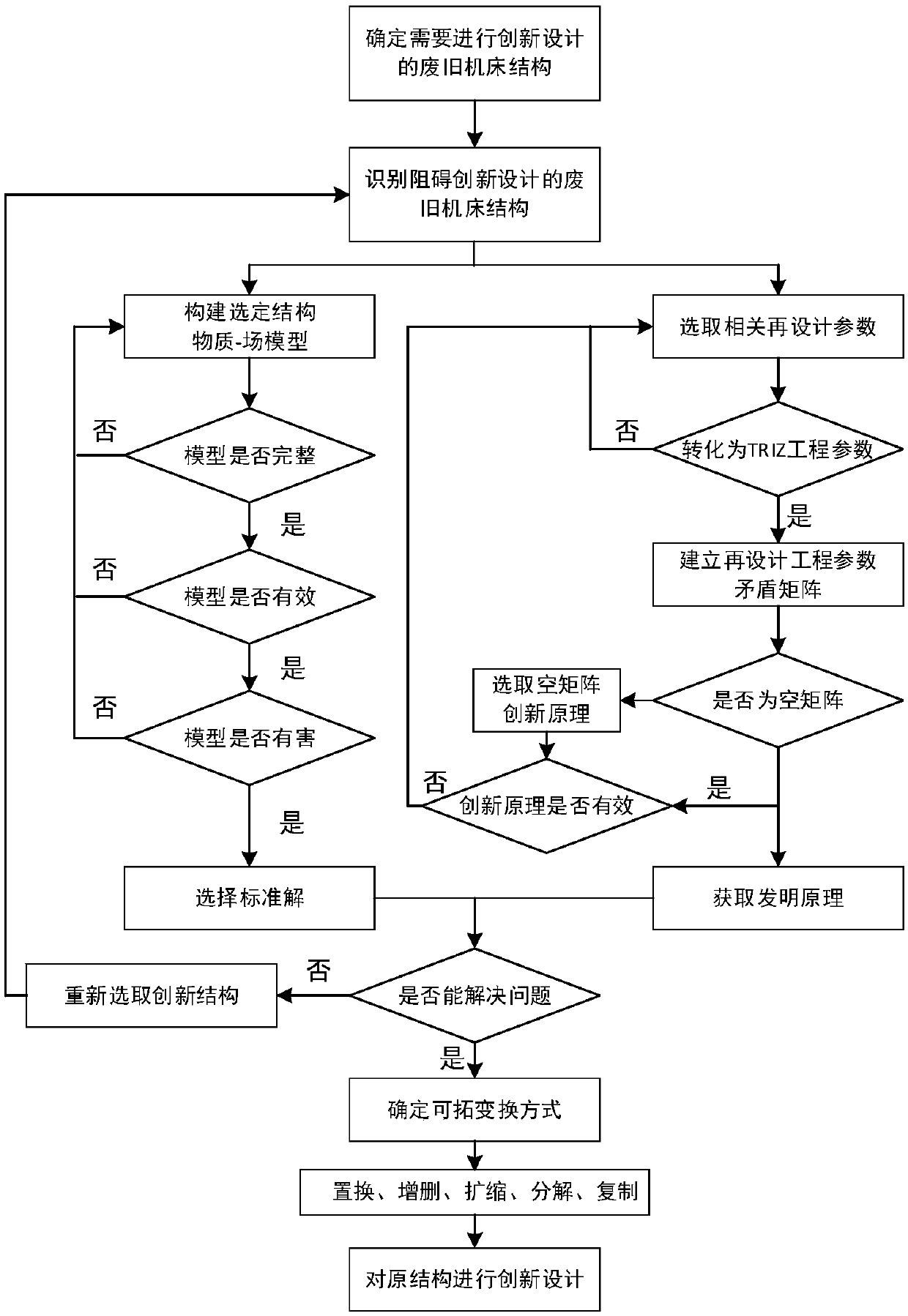

Method used

Image

Examples

Embodiment Construction

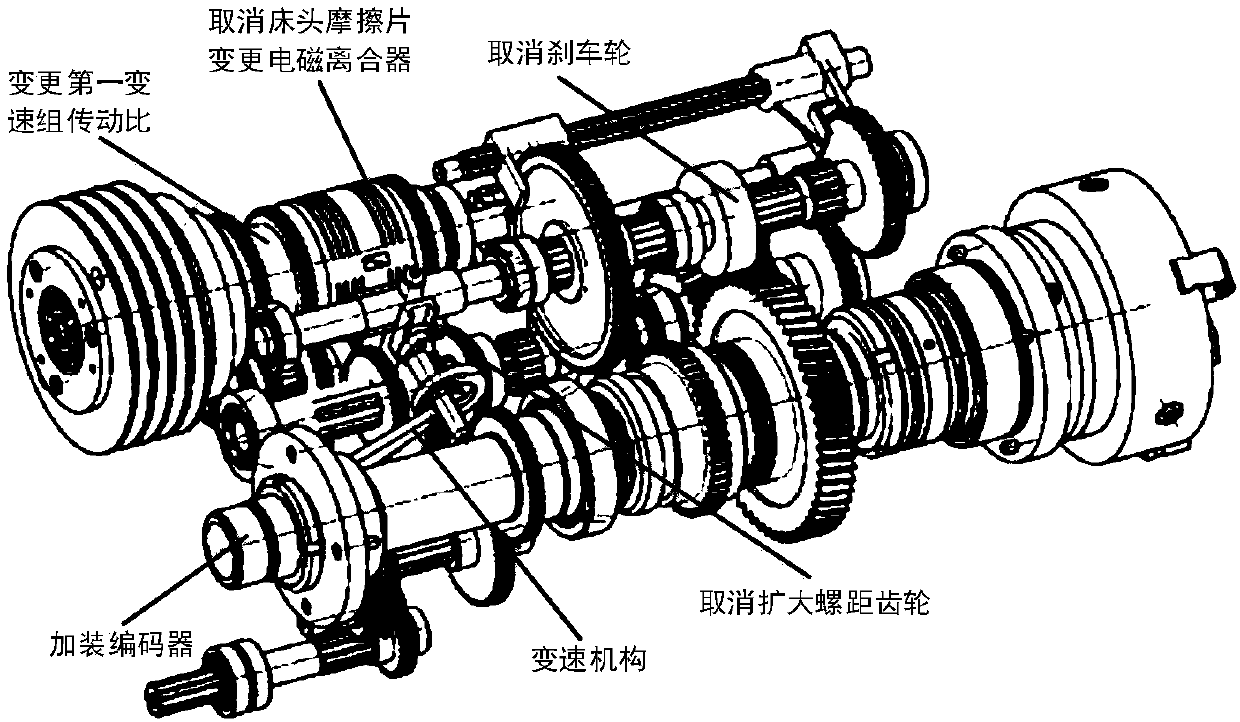

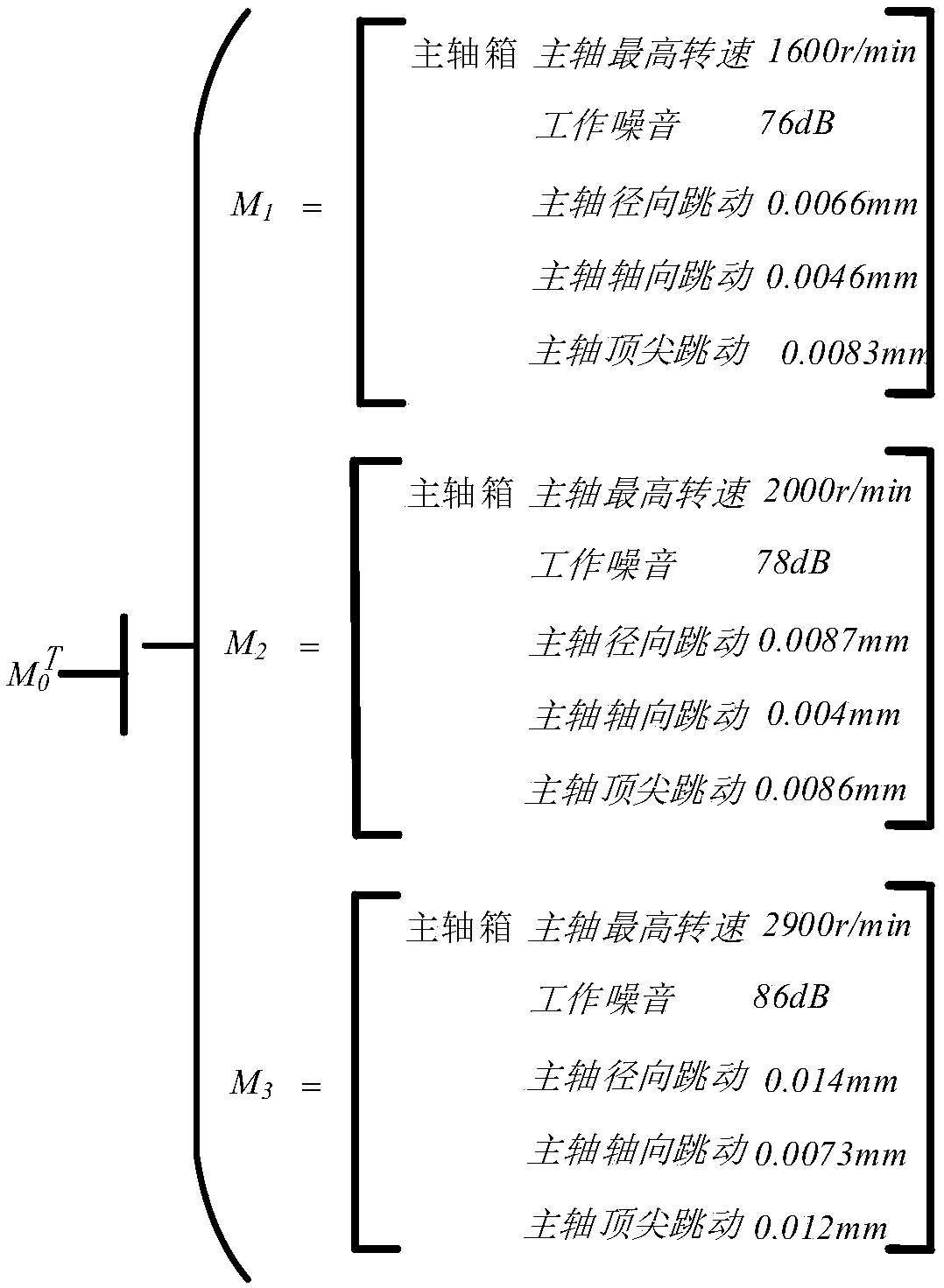

[0049] The specific operation steps of the present invention will be described in conjunction with the accompanying drawings and examples. The main drive structure of the headstock has a decisive influence on the machining accuracy of the machine tool. Therefore, when remanufacturing the waste machine tool, it is of practical significance to remanufacture the innovative design of the headstock to improve its performance. The factory currently recycles the waste CA6140 headstock spindle with a maximum rotation speed of 1400r / min, a minimum rotation speed of 11r / min, and a 24-stage variable speed. The main drive motor model is Y132M-4. By selecting typical structural features, the matter-element model M of the original waste spindle box was established 0 as follows:

[0050]

[0051] Through market research, if the remanufactured machine tool is guaranteed to have sufficient market competitiveness, the corresponding characteristic index that it should achieve, that is, the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com