Motor rotor, sewing machine energy saving motor by employing motor rotor and sewing machine of motor rotor

A motor rotor, sewing machine technology, applied in the direction of sewing machine components, sewing machine control devices, sewing equipment, etc., can solve the problems of magnetic tile falling off, troublesome operation of workers, motor damage, etc., to achieve the effect of avoiding falling off, firm assembly and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

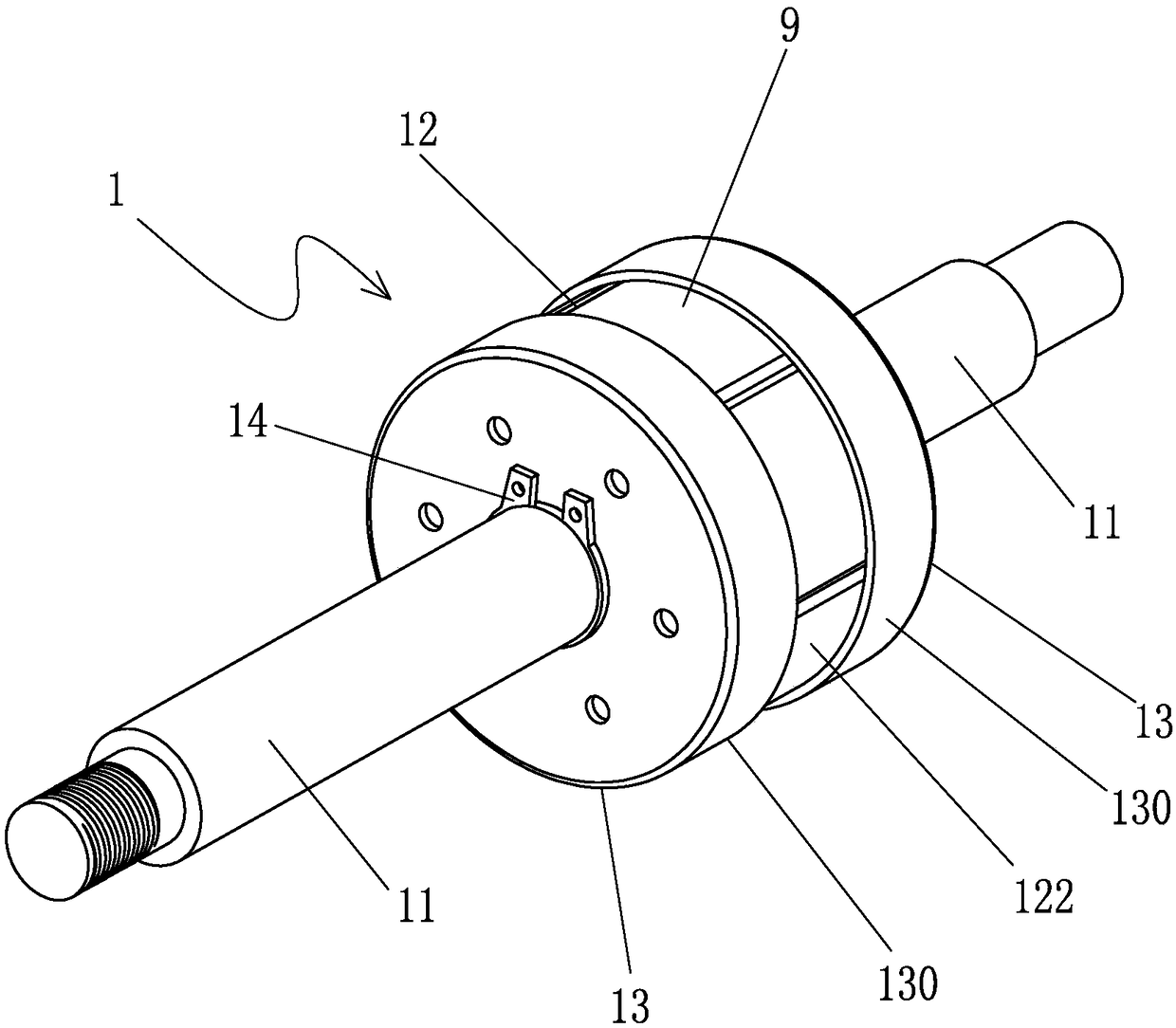

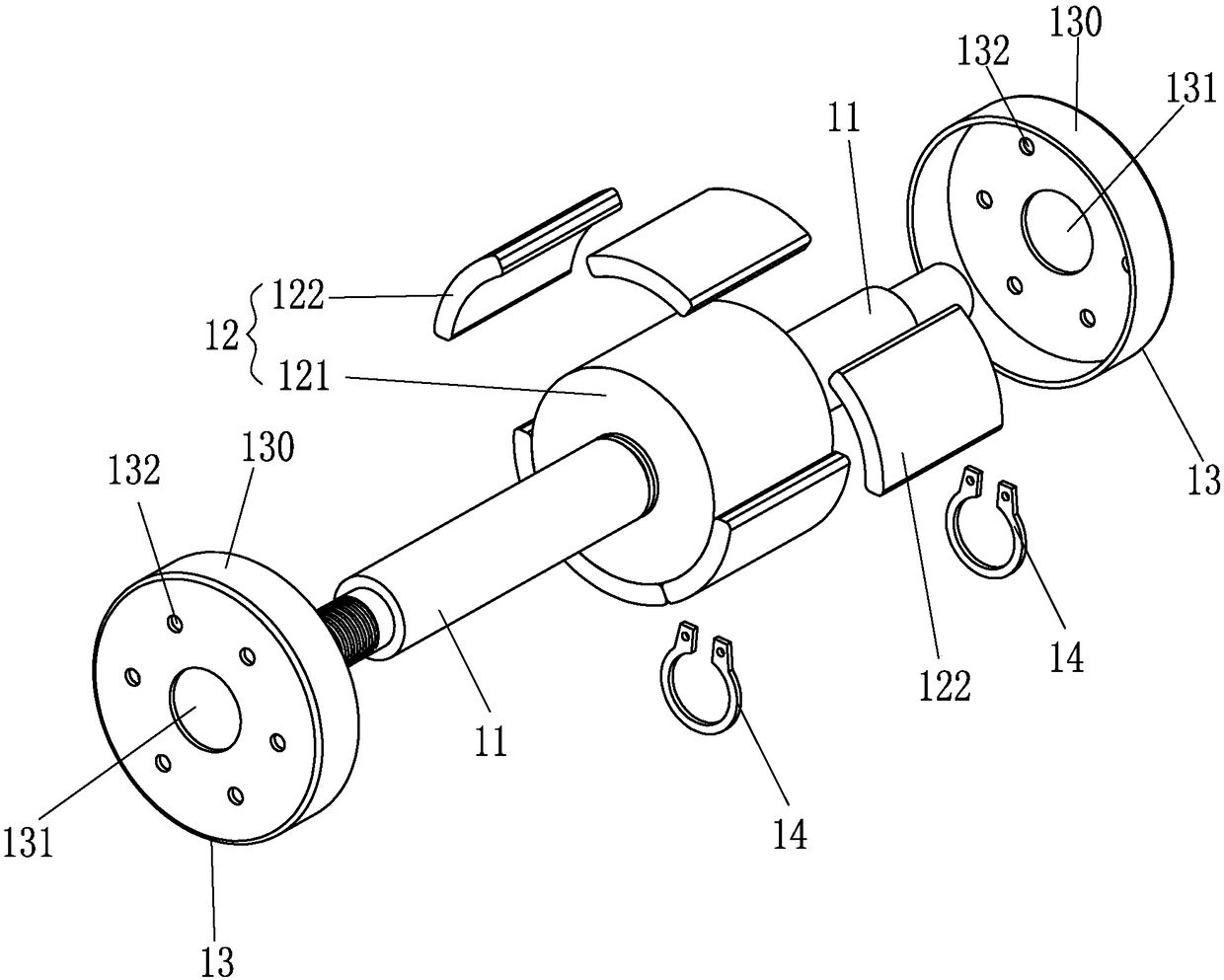

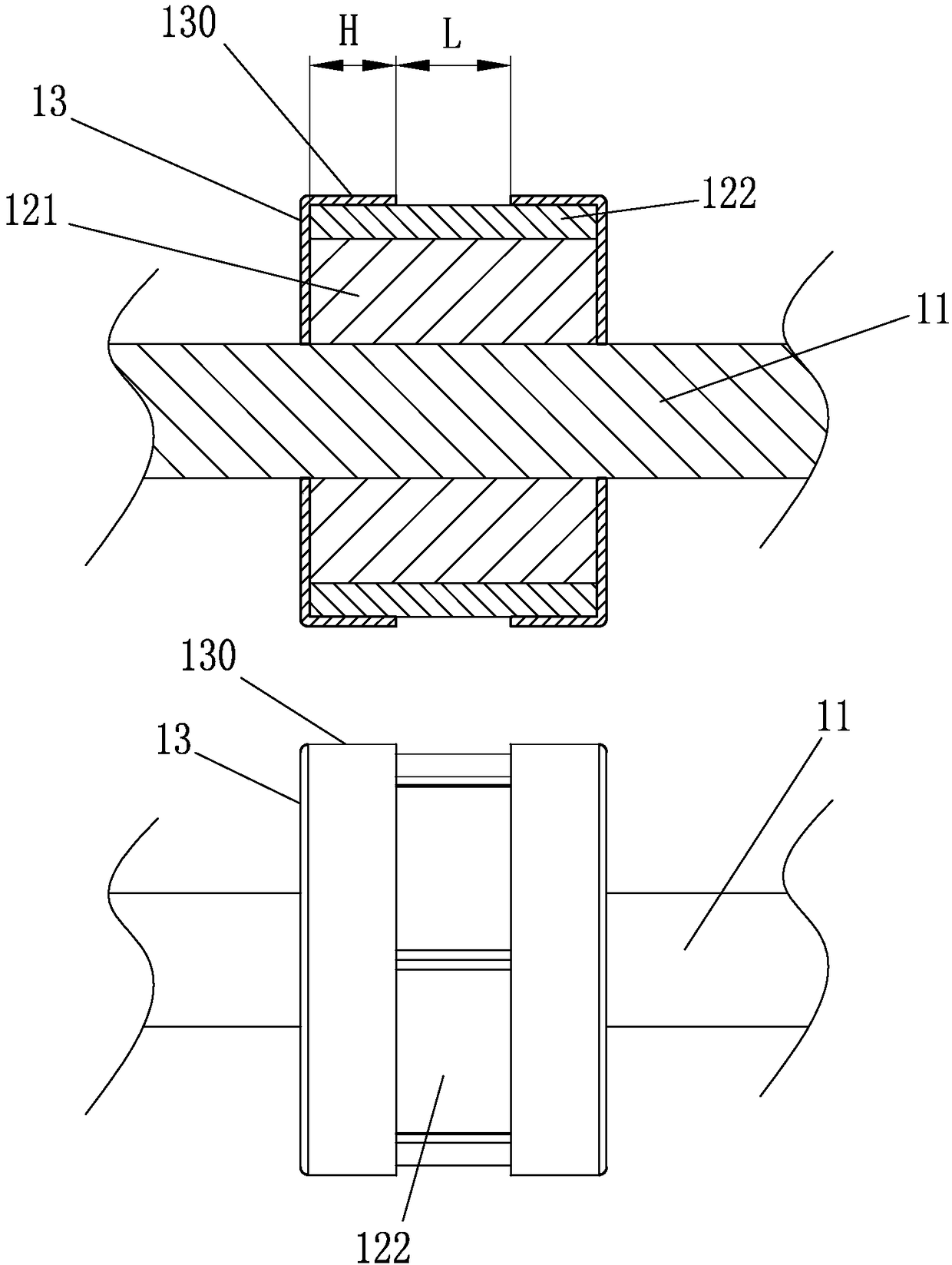

[0026] Attached below Figures 1 to 6 The present invention is described further:

[0027] A motor rotor, the motor rotor 1 includes a rotating shaft 11 and a rotor main body 12 arranged on the rotating shaft 11, the rotor main body 12 includes an inner core 121 and several magnetic tiles 122 distributed on the outer peripheral surface of the inner core 121, the The two ends of the rotor main body 12 are covered with end caps 13, and the circumferential direction of the end caps 13 has an annular flange 130 and the annular flange 130 encloses the magnetic tile 122, and the two end caps 13 An annular groove 9 is formed between the annular flanges 130 so that part of the magnetic tile 122 is exposed. The annular flange 130 of the end cover 13 can wrap the magnetic tile 122, thereby avoiding the falling off of the magnetic tile, ensuring the stability of the product, and making the motor rotor of the present invention firmly assembled; the annular groove 9 makes part of the magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com