Roller coating brush

A technology of roller coating and roller brush head, applied in the field of roller coating and brushing, can solve the problems of poor integrity of roller coating and brushing, consuming labor and time of construction personnel, uneven roller coating on the working surface of roller coating, etc., and achieve the effect of good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

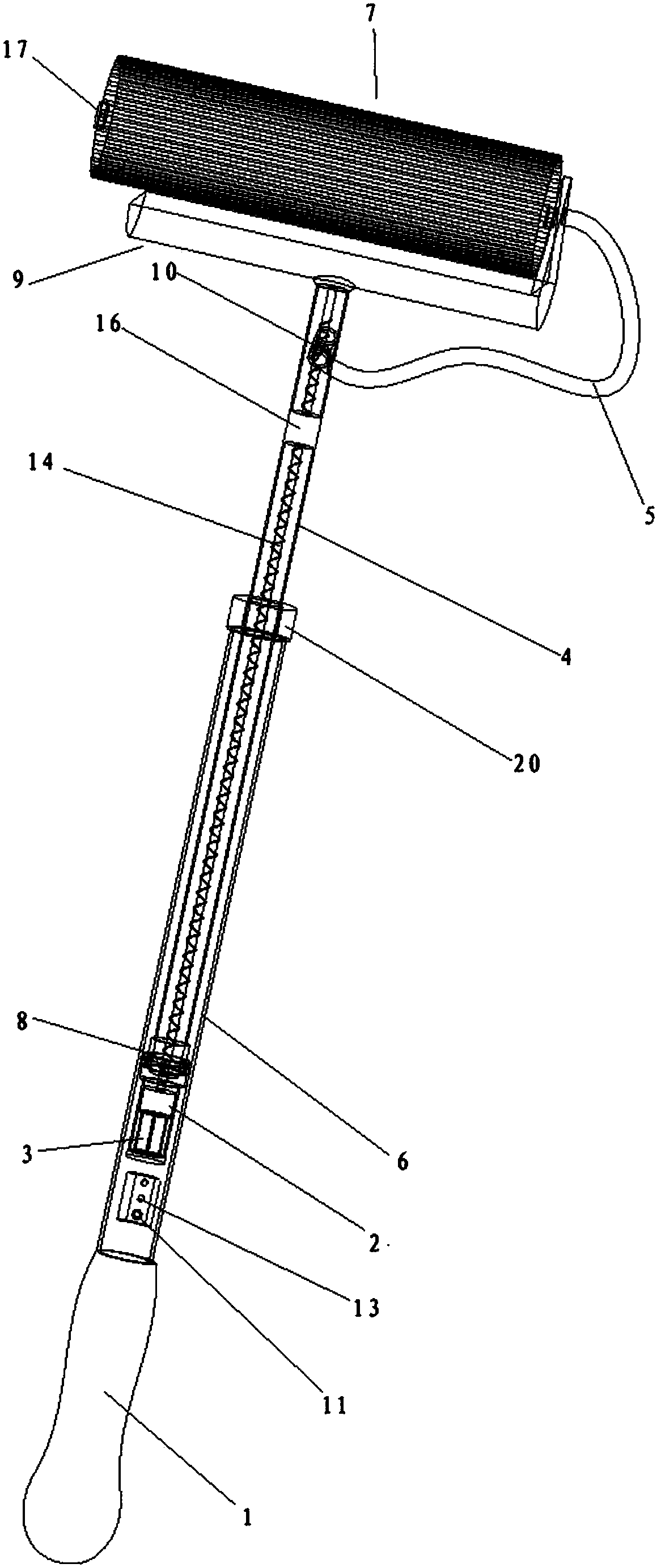

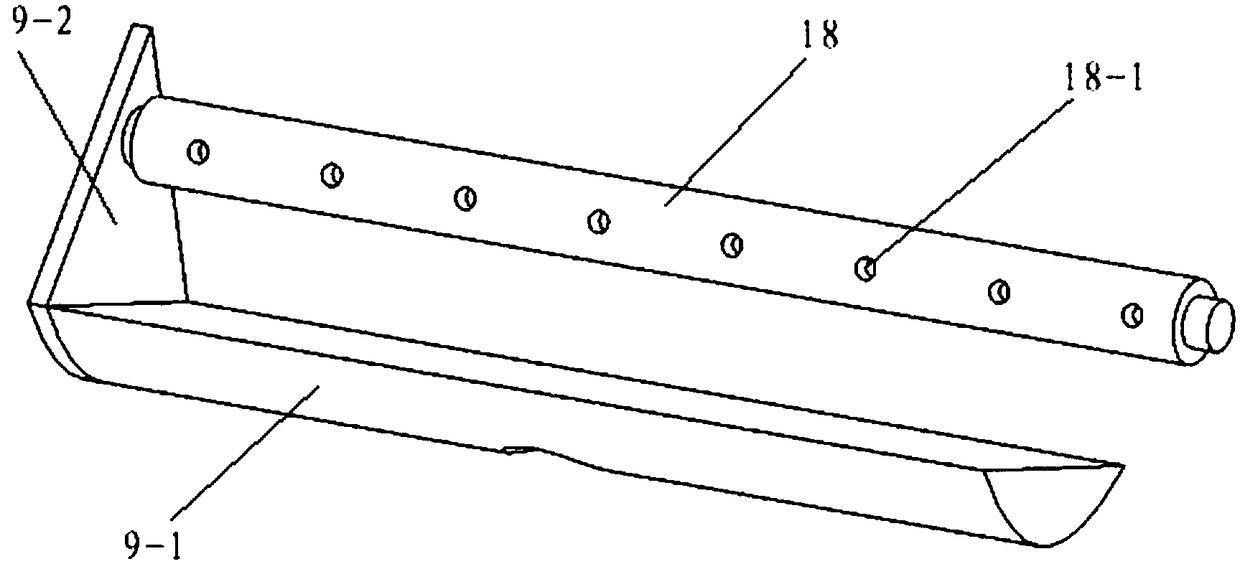

[0034] Such as figure 1 and 2 Shown, be the roller brushing of present embodiment, comprise section and be " L " type roller brush head bracket 9, on the roller brush head bracket 9 horizontally fix hollow shaft 18, one end of hollow shaft 18 is fixed on the roller brush head bracket 9 and connected to one end of the feeding hose 5, the other end of the hollow shaft 18 is suspended and sealed, and the outer surface of the hollow shaft 18 is provided with a discharge hole 18-1 communicating with the inner cavity of the hollow shaft.

[0035] Such as figure 2 As shown, the "L" shaped brush head bracket 9 includes an arc-shaped base plate 9-1 and a mounting plate 9-2 arranged on the base plate 9-1. The bottom plate of the arc-shaped rolling brush universal support can block the splashed liquid droplets when the rolling brush works.

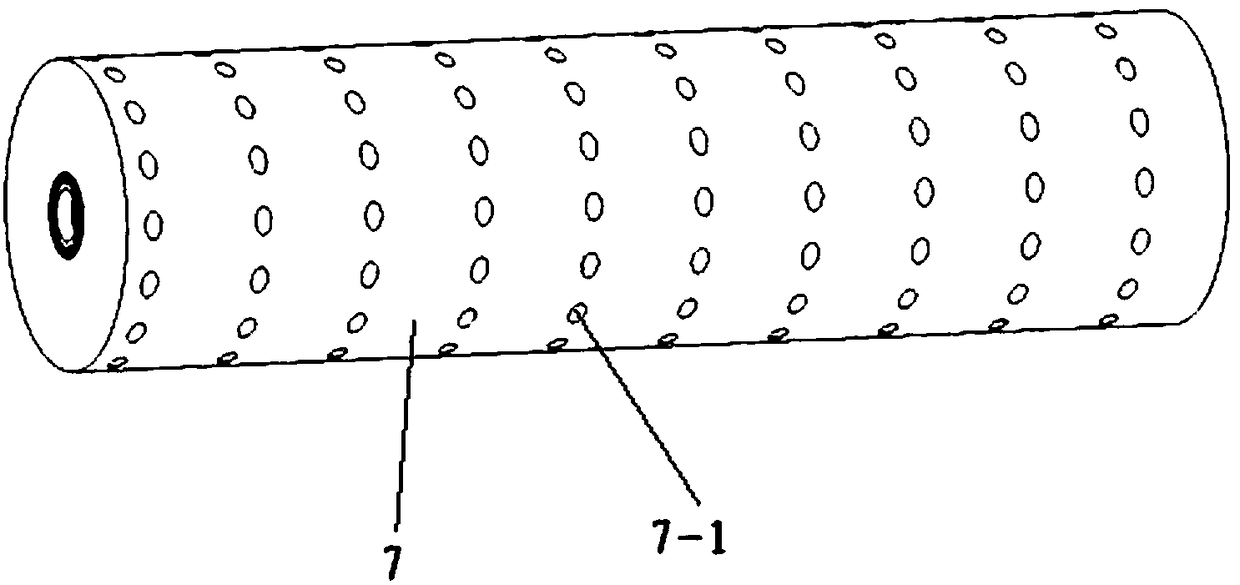

[0036] Such as image 3 As shown, the rolling brush head 7 is set on the outer surface of the hollow shaft 18, and the two ends of the rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com