Cleaning tool

A technology for cleaning tools and positioning mechanisms, applied to cleaning equipment, household appliances, handles, etc., can solve problems such as the drop of the machine head, the inconvenience of stable application of force on the body components, and the falling off of the machine head, so as to achieve the effect of easy movement or operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

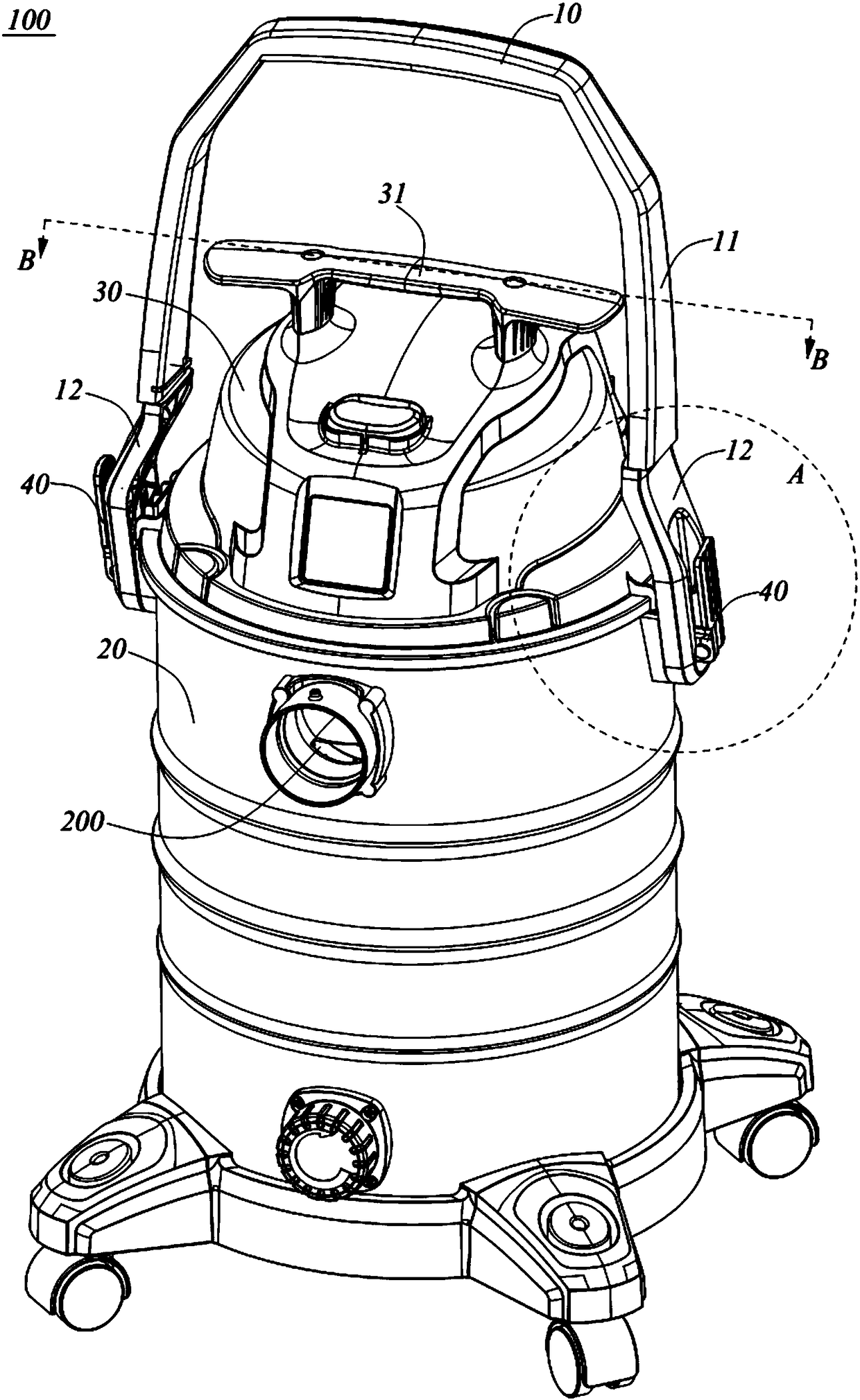

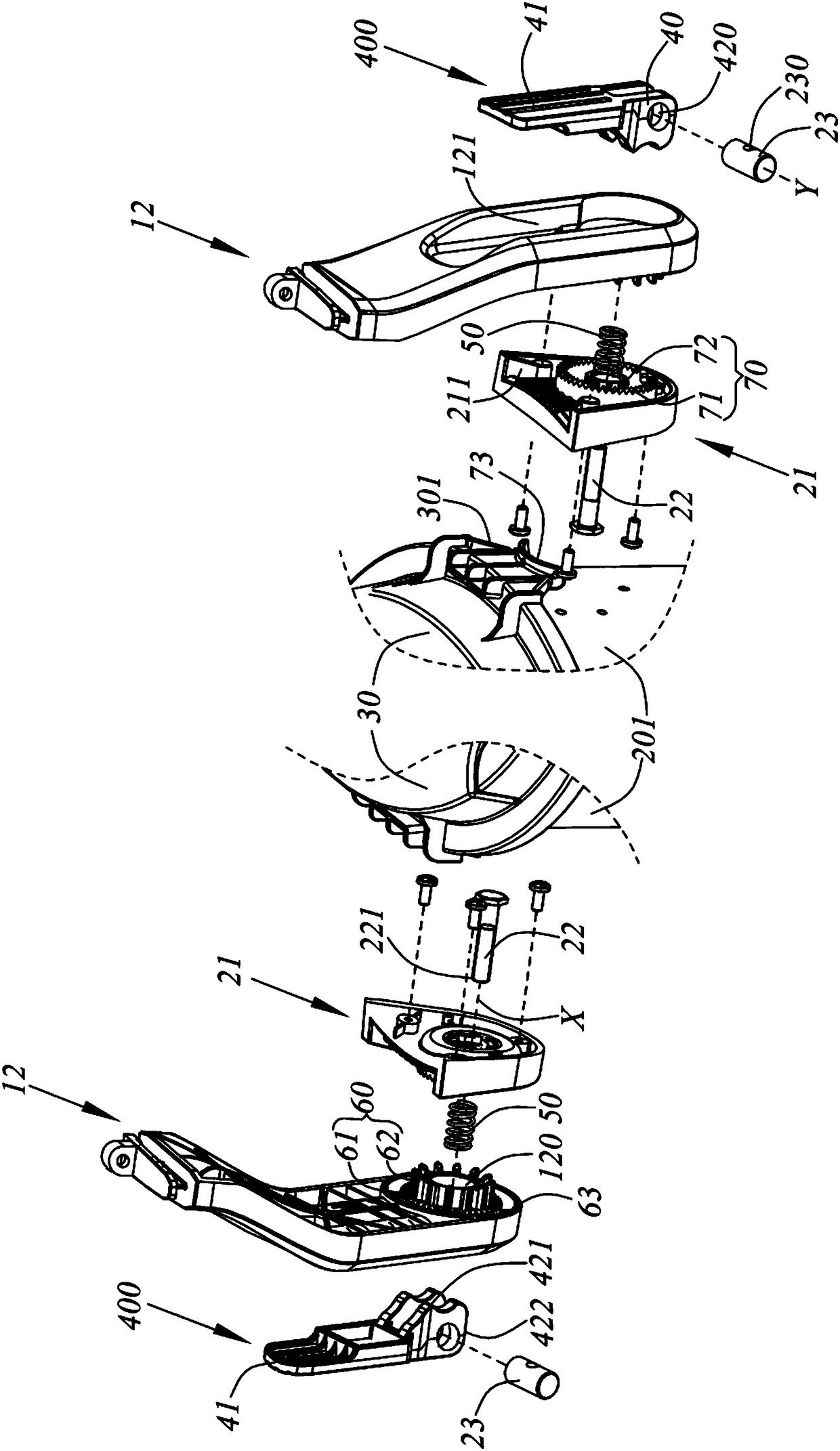

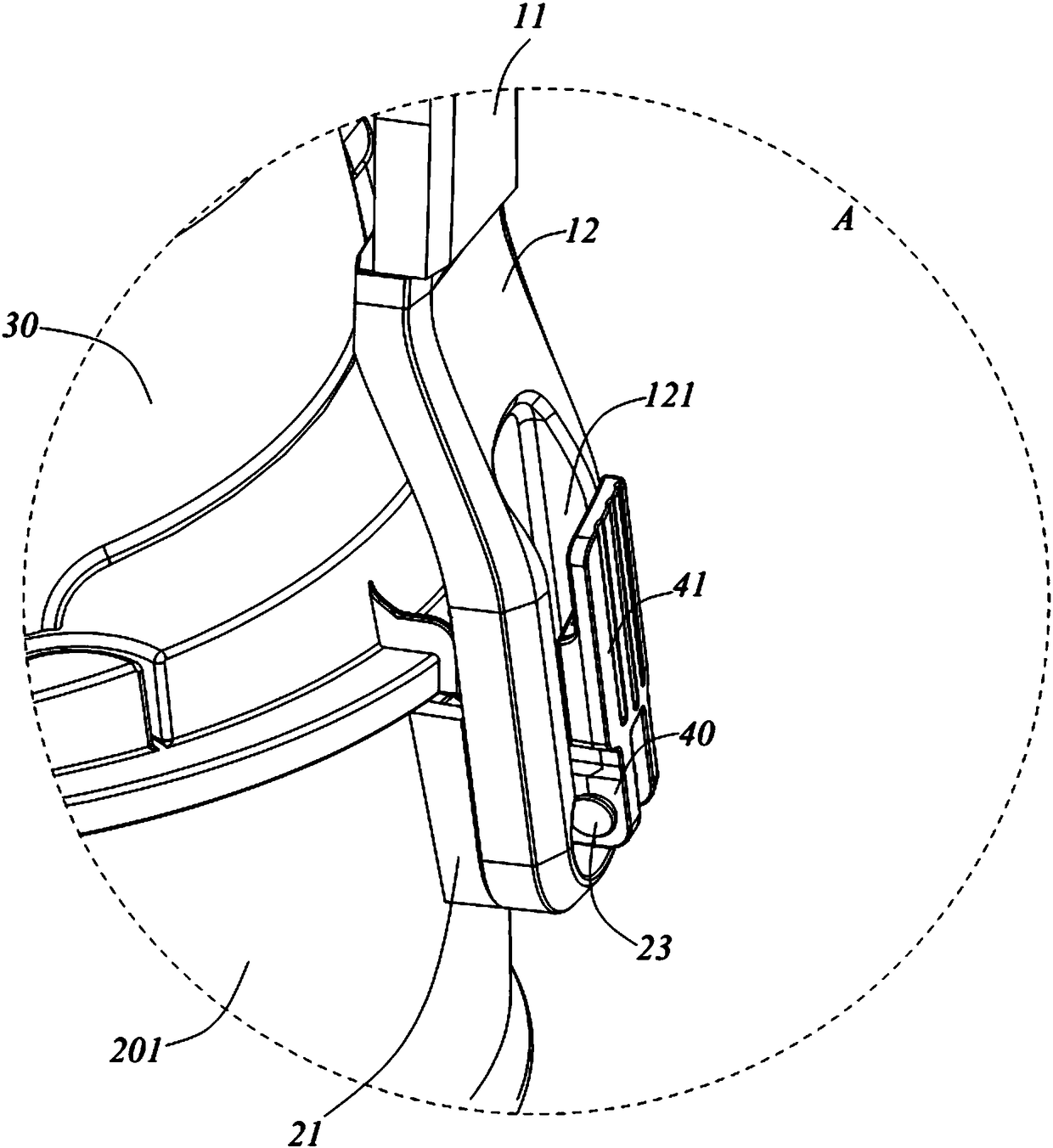

[0057] Such as figure 1 and figure 2 As shown, an embodiment of the present invention discloses a cleaning tool 100, and the cleaning tool 100 can be specifically configured as a bucket type wet and dry vacuum cleaner. The cleaning tool 100 includes a working head assembly (not shown), a body assembly, a handle assembly 10 and a driving assembly. Wherein, the working head assembly includes any one of ground brush, round brush, dust brush, flat suction or other types of brushes or suction heads, and the working head assembly is connected to the fuselage assembly through a hose. Interface 200; the fuselage assembly includes a fuselage body; the handle assembly 10 is connected to the fuselage body through a first connecting shaft 22, and the handle assembly 10 can rotate around a first axis X relative to the fuselage body , which includes a handle body 11 for the operator to hold.

[0058] ginseng Figure 1 to Figure 8 , the cleaning tool 100 has a locked state and a release...

Embodiment 2

[0088] see Figure 9 to Figure 11 , another embodiment of the present invention, this embodiment discloses a cleaning tool. The cleaning tool includes a handle assembly, a body assembly, a driving assembly, a working head assembly and an unlocking mechanism. The difference between the cleaning tool 100 in this embodiment and the cleaning tool 100 in Embodiment 1 lies in the structure of the handle assembly, the structure of the drive assembly, the structure of the unlocking mechanism and the structure of the limit mechanism. These differences will be introduced below , other components / structures that are the same as those in Embodiment 1 will not be repeated here.

[0089] In this embodiment, the handle assembly 10' includes a handle body 11' for the operator to hold, and a positioning mechanism 12' connected to the handle body 11'.

[0090] Specifically, the handle body 11' includes a U-shaped piece 111, a first support piece 112 connected to the end of the U-shaped piece ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap