Multifunctional filter press

A filter press, multi-functional technology, applied in the fields of filtration and separation, water/sludge/sewage treatment, sludge treatment, etc., can solve the problem of inconvenient disassembly of the filter plate, etc., and achieve the effect of ensuring stability and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

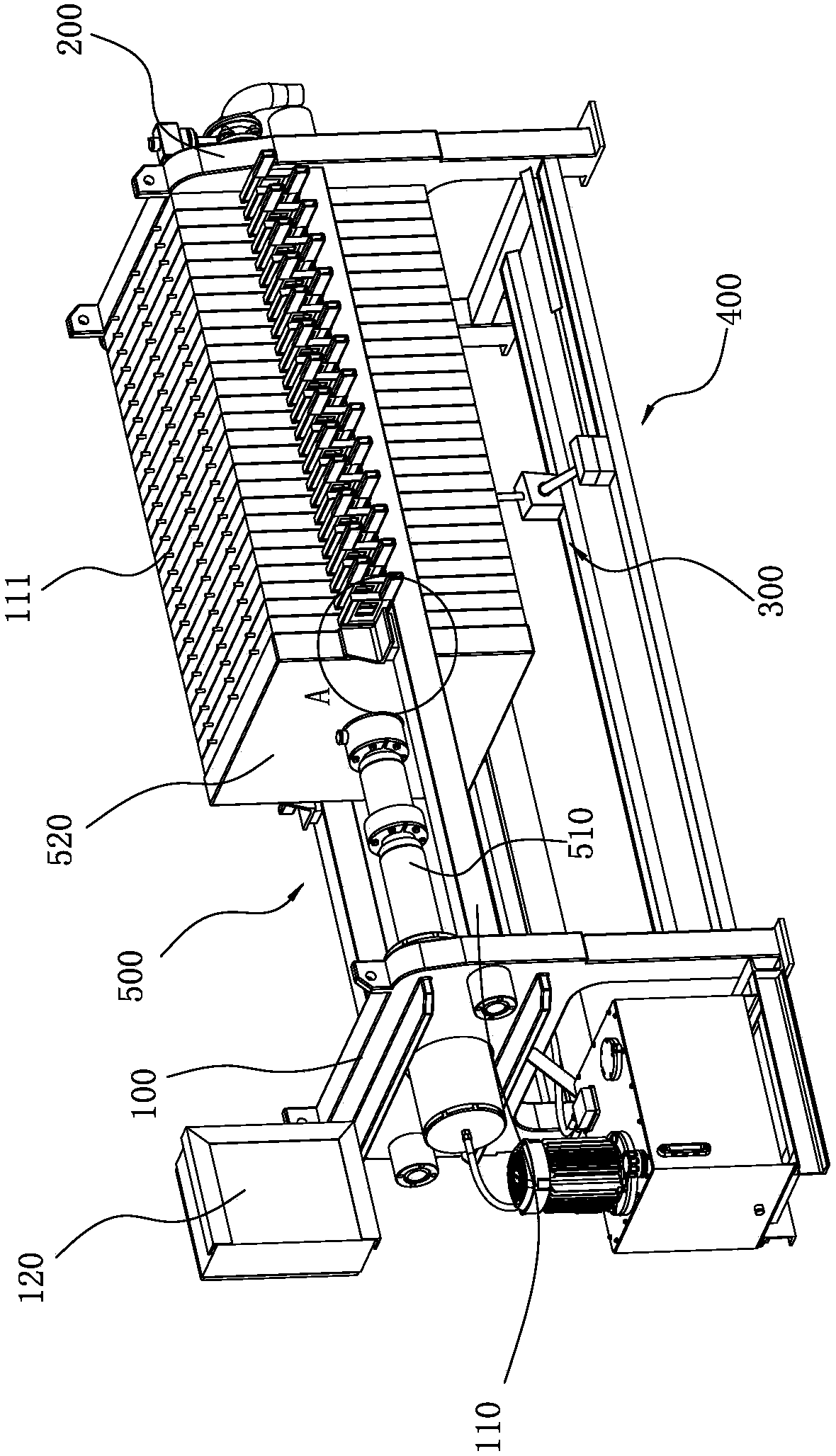

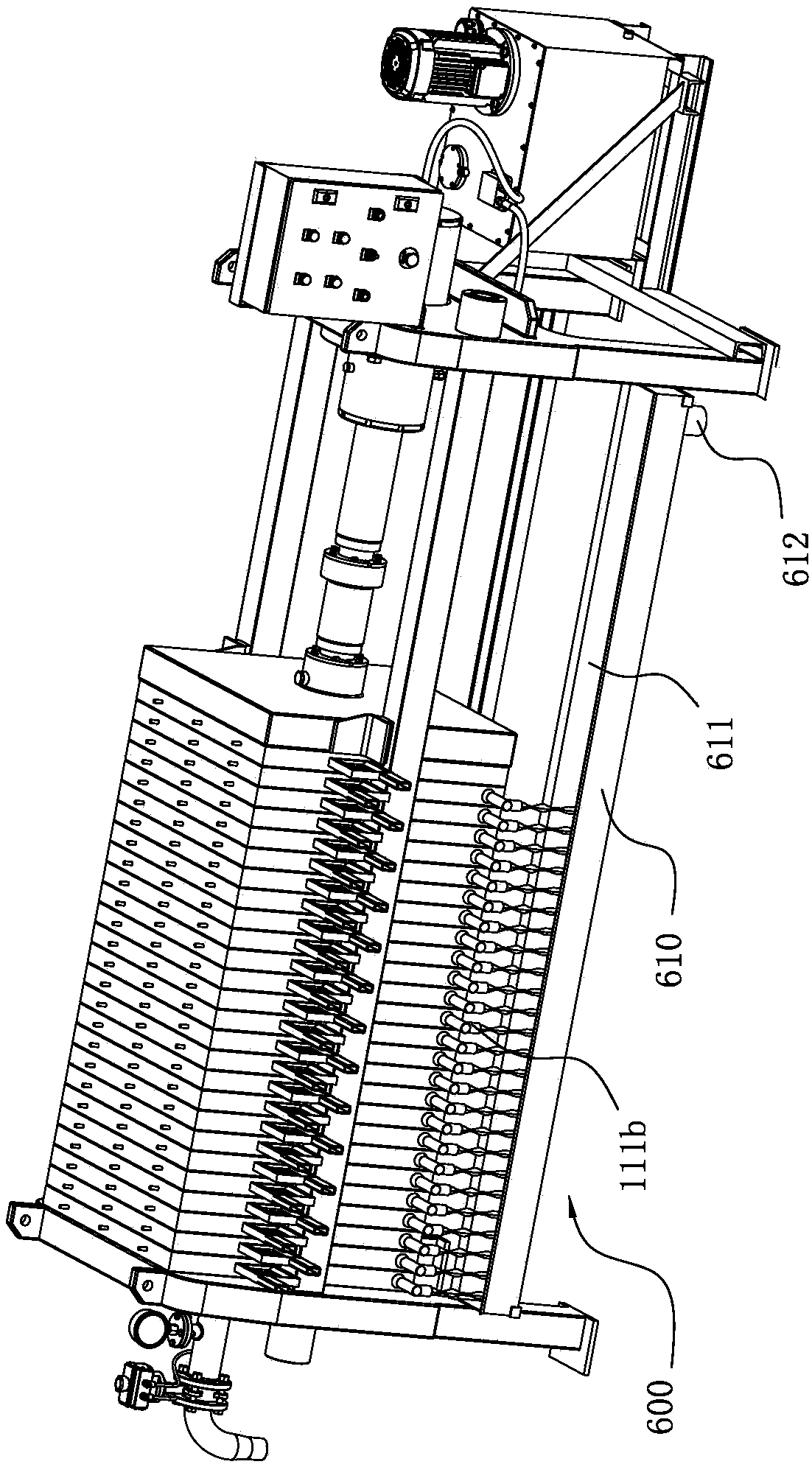

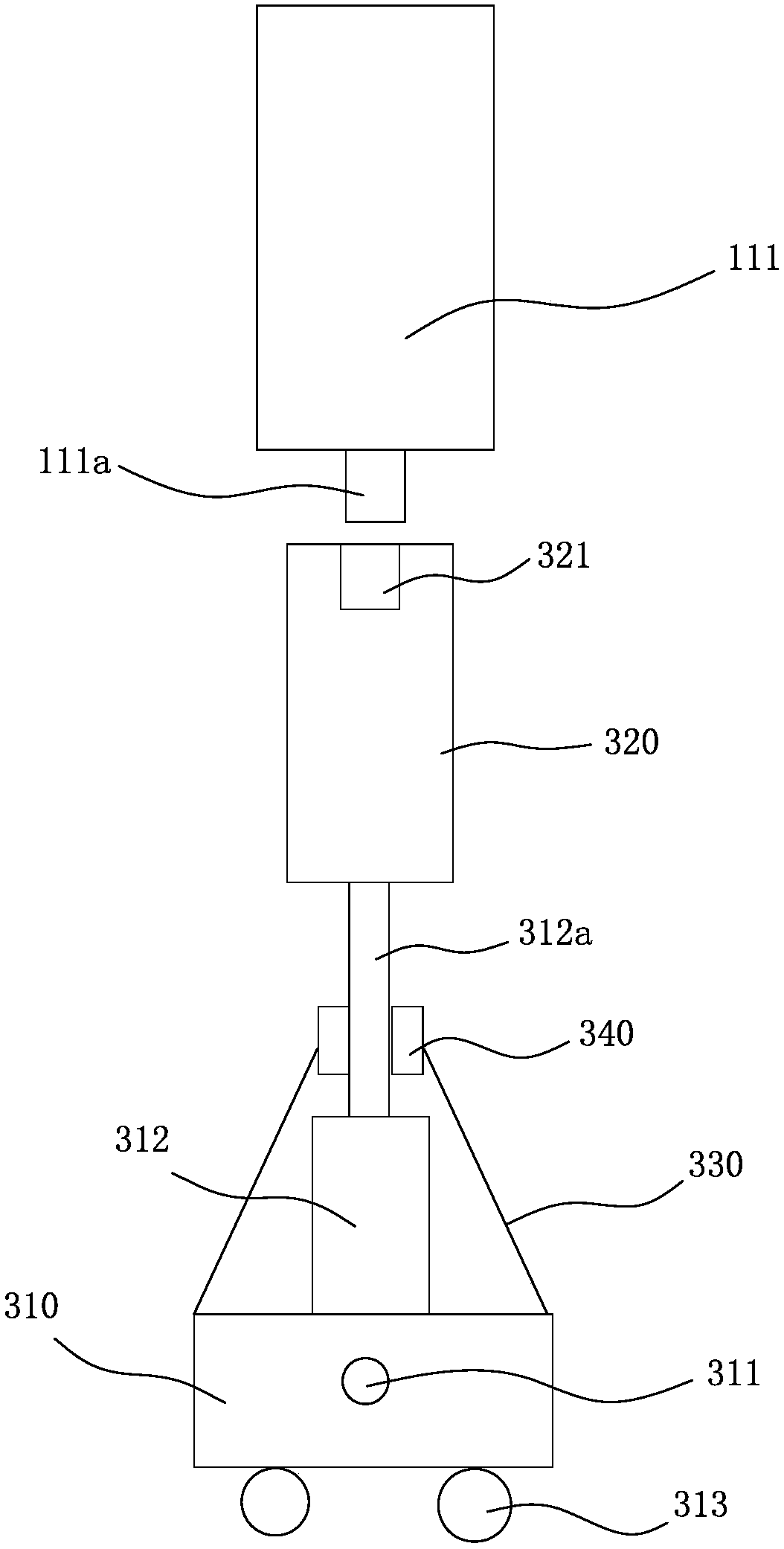

[0029] Such as figure 1 — Image 6 As shown, a multifunctional filter press of the present invention includes a front seat 100, a rear seat 200, a guide rod 110, a filter plate 111, a push plate mechanism 300, a movable seat 320, a first oil cylinder 312, a piston rod 312a, a top plate 320, a The dust cover 330 , the fastening mechanism 400 , the pressing device 500 , the drainage mechanism 600 and the controller 120 .

[0030] One side of the front seat 100 is provided with a rear seat 200, and two guide rods 110 are interposed between the front seat 100 and the rear seat 200, and a plurality of filter plates 111 are clamped between the two guide rods 110. A plurality of filter plates 111 are fastened to the pressing de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com