Edge rolling method for cloths

A cloth and hemming technology, which is applied in the hemming field of fabrics, can solve problems such as hemming loose, uneven hemming width, unqualified sewing of hemming width, etc., and achieve the effect of fast and convenient folding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

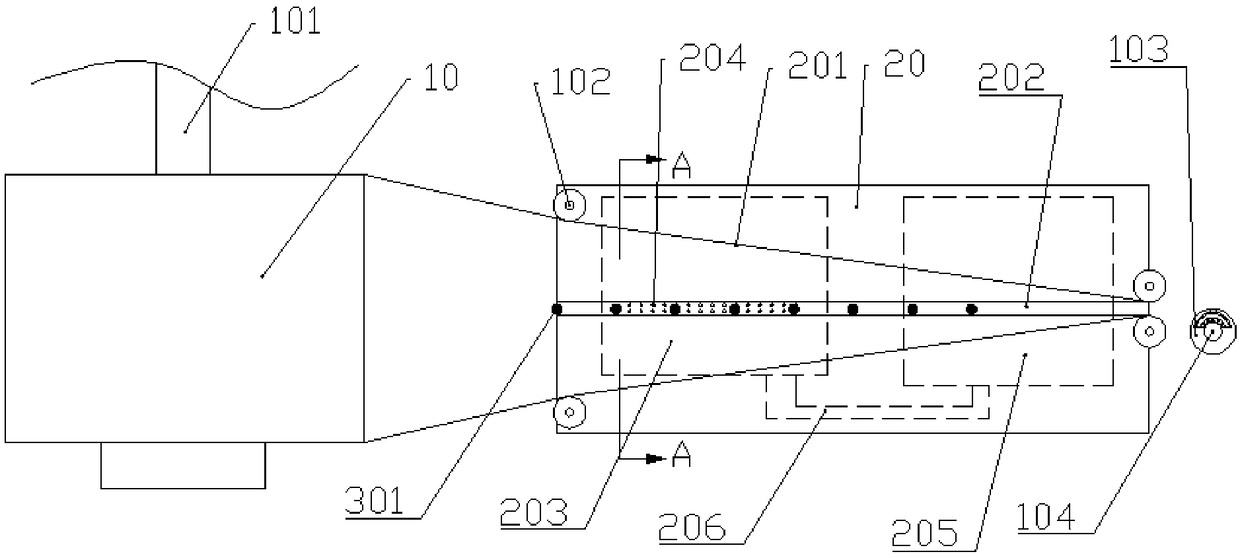

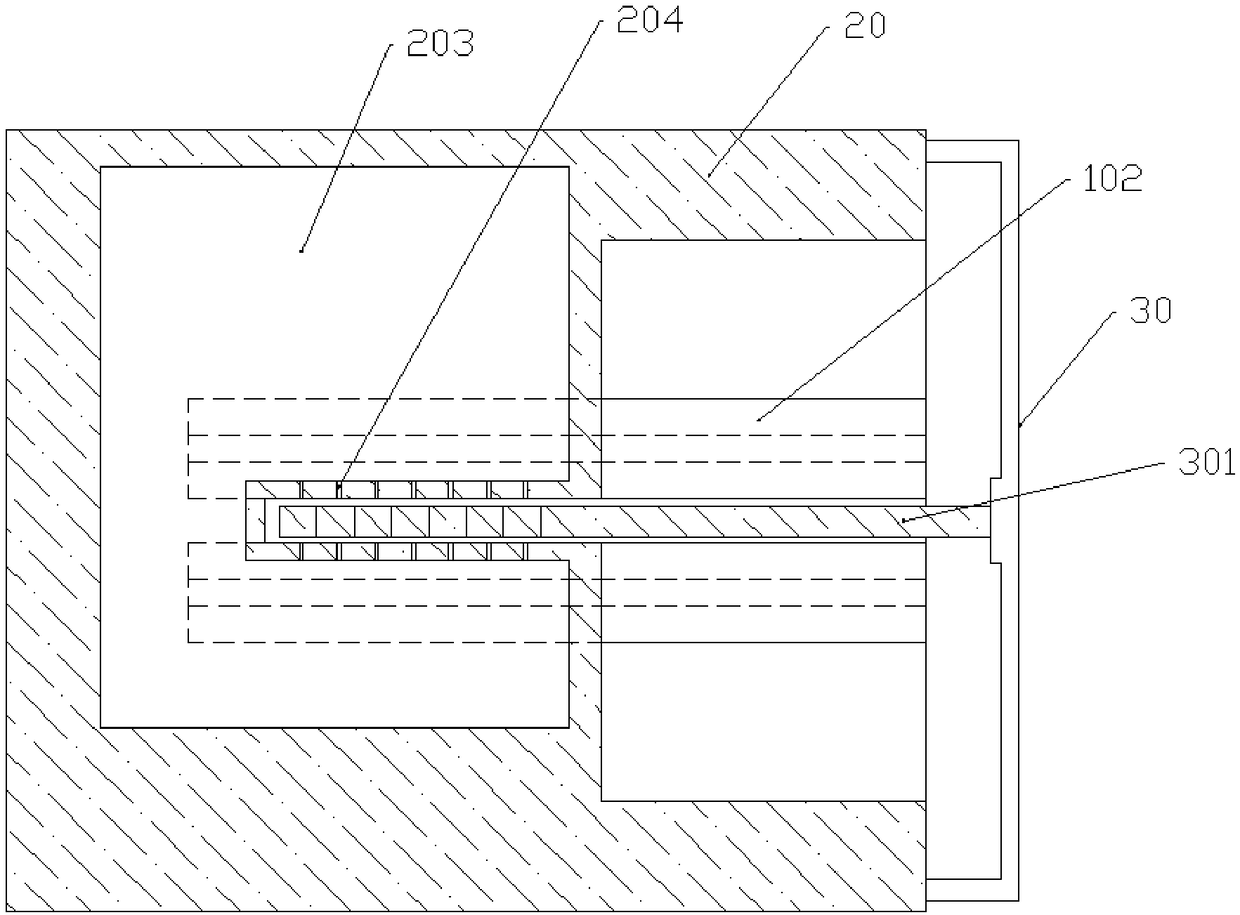

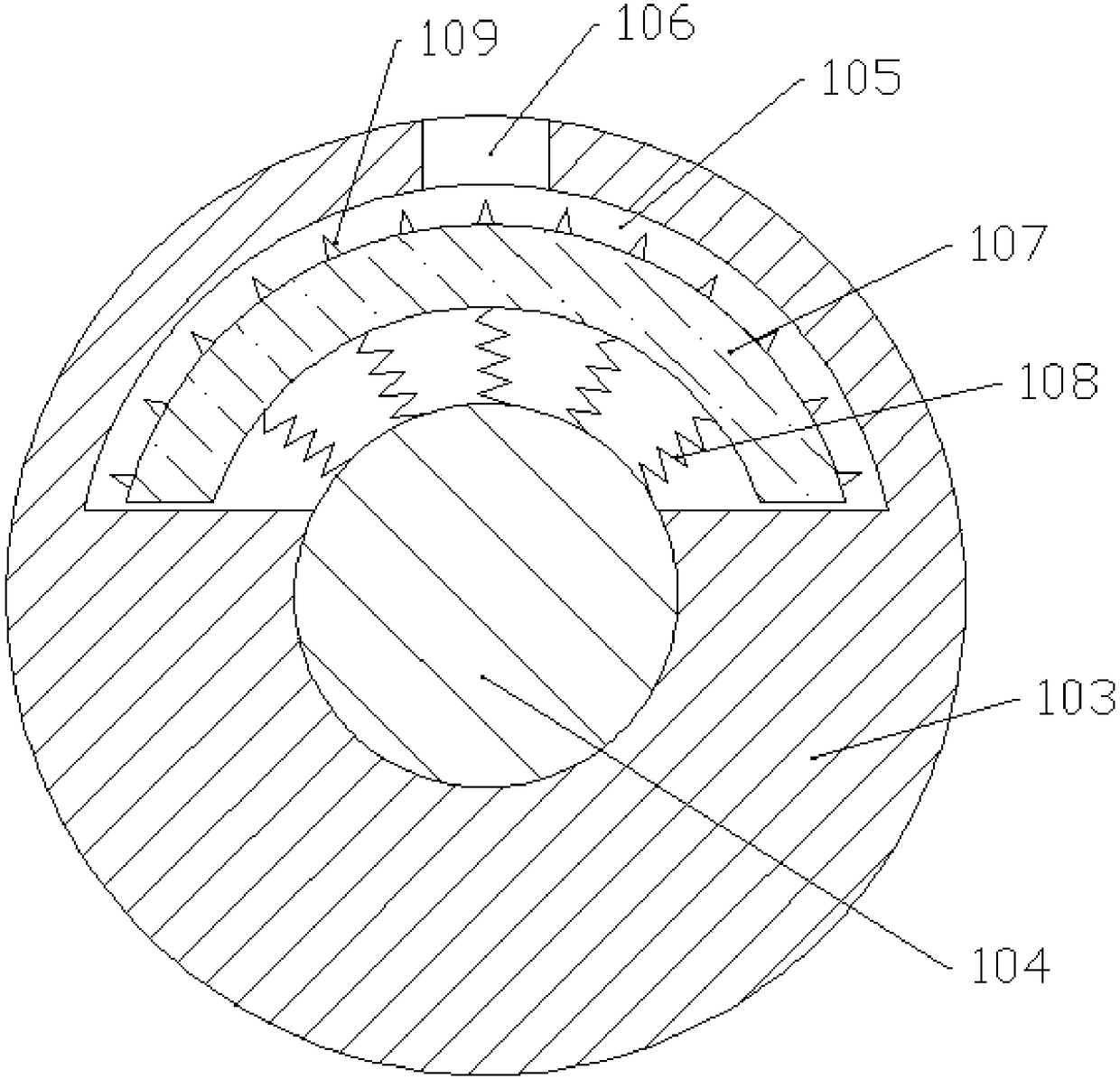

[0019] The reference numerals in the accompanying drawings of the description include: unwinding roller 10, first shaft 101, delivery roller 102, winding roller 103, second shaft 104, pressing chamber 105, bar-shaped hole 106, pressing block 107, spring 108, pressing tooth 109, limit block 20, guiding channel 201, crimping channel 202, accommodation chamber 203, steam hole 204, drying chamber 205, heat preservation pipe 206, support rod 30, ejector rod 301.

[0020] The concrete steps of the method in the present embodiment are as follows:

[0021] Step 1: Prepare 8L of distilled water and several rolls of fabric to be hemmed;

[0022] Step 2: Prepare the basics as attached figure 1 , attached figure 2 And attached image 3 The crimping device shown includes a transmission mechanism, a crimping mechanism and a supporting mechanism.

[0023] The transmission mechanism includes an unwinding r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com