Modular type scaffold and erecting method thereof

A kind of scaffolding and modularization technology, which is applied to the accessories of scaffolding, the connection of scaffolding, the support of building structure, etc., can solve the problems of cumbersome operation and long time consumption, and achieve the effect of convenient operation, low production cost and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

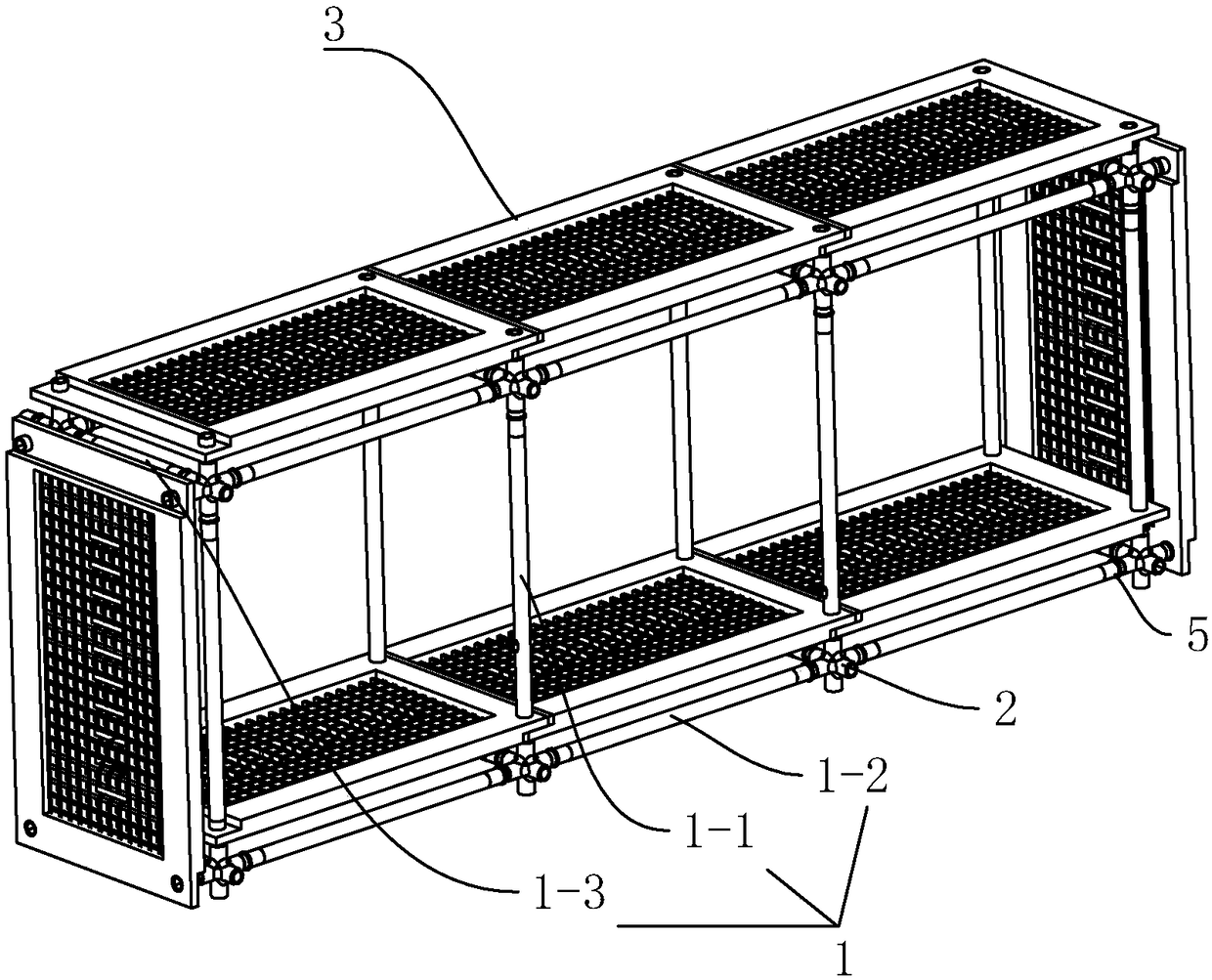

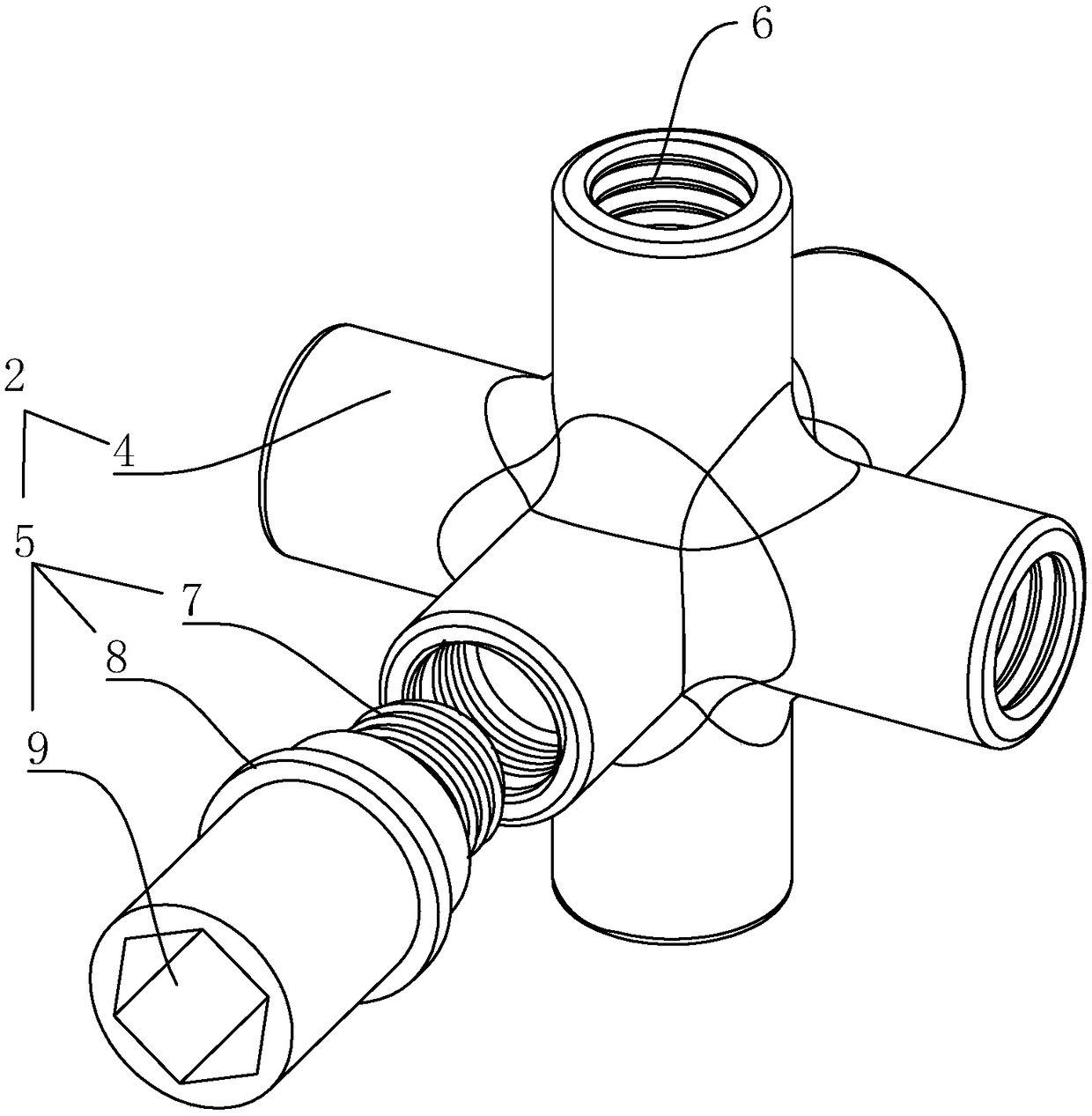

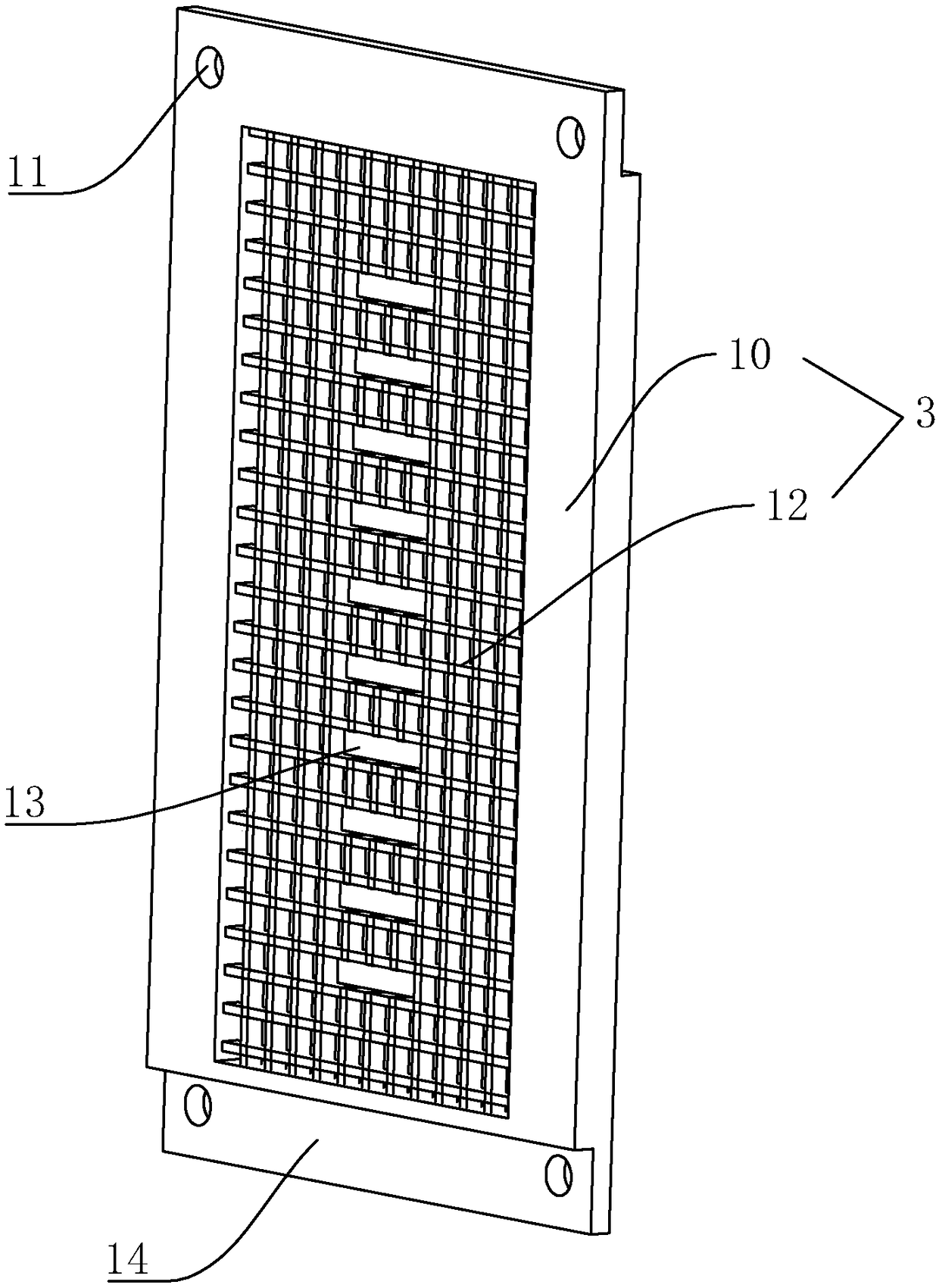

[0046] Embodiment one, a kind of modular scaffolding, refer to figure 1 , including connecting pipe fittings 1 as vertical pipe fittings 1-1, horizontal pipe fittings 1-2 and longitudinal pipe fittings 1-3, and the lengths between various pipe fittings can be customized according to actual needs. It also includes a coupling piece 2 that can be connected to both ends of the connecting pipe piece 1, and can also connect connecting pipes 5 in different directions. After connecting different types of connecting pipe pieces 1 and multiple coupling pieces 2, a defined interior with different heights can be formed. space. Then install the plate frame 3 on the connector 2 in the horizontal or vertical direction, and the plate frame 3 plays the roles of support plate and protective plate; the plate frame 3 also relatively fixes the connector while fixing the connector 2 2 The connection with the pipe fittings strengthens the overall structural strength of the scaffold.

[0047] refer...

Embodiment 2

[0054] Embodiment 2, a method for erecting the modular scaffolding in the splicing embodiment 1, comprising the following steps:

[0055] -S1: making a plurality of six-way mounting seats 4 equipped with a plurality of connecting pipes 5 as connectors 2;

[0056] -S2: Two horizontal pipe fittings 1-2 and two longitudinal pipe fittings 1-3 are respectively connected with four connecting pieces 2 to form a back-shaped frame as the bottom end of the scaffold;

[0057] -S3: Sleeve the positioning hole 11 in the plate frame 3 as a supporting plate onto the connecting pipe 5 at the upper end of the coupling piece 2 assembled in step 2, and then insert the connecting pipe 5 at the upper end of each coupling piece 2 Connect the vertical pipe fitting 1-1;

[0058] -S4: When the scaffolding needs to be erected sequentially in the vertical direction, the vertical pipe fittings 1-1 can be inserted into the return frame assembled in step 2; when erecting in the horizontal direction, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com