Clean energy converter

A clean energy and converter technology, which is applied in the direction of machines/engines, impregnated lubrication or splash lubrication, friction transmissions, etc., can solve the problems of the engine not working hard, fuel consumption, etc., to reduce energy loss, reduce noise and friction , The effect of stable mechanical operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

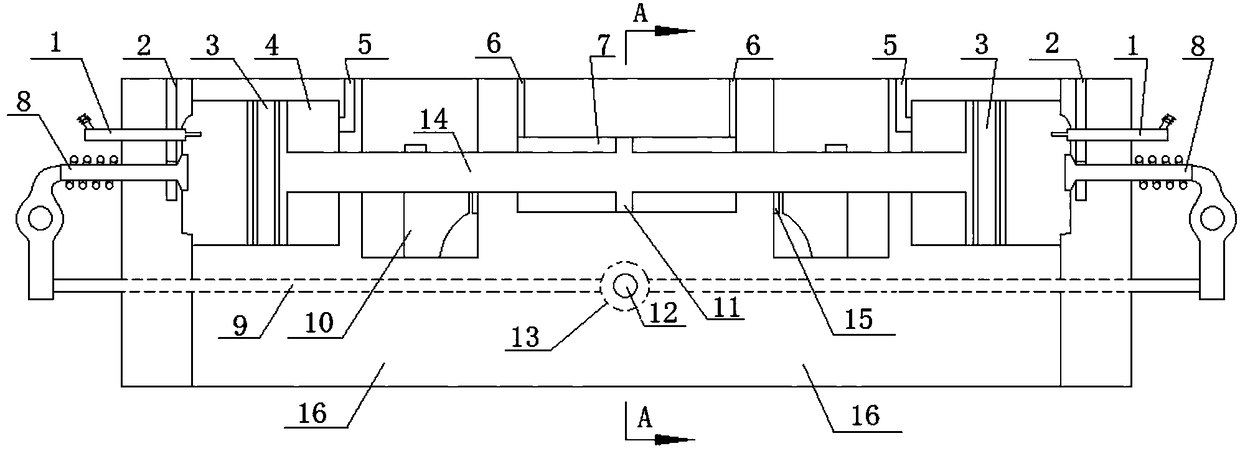

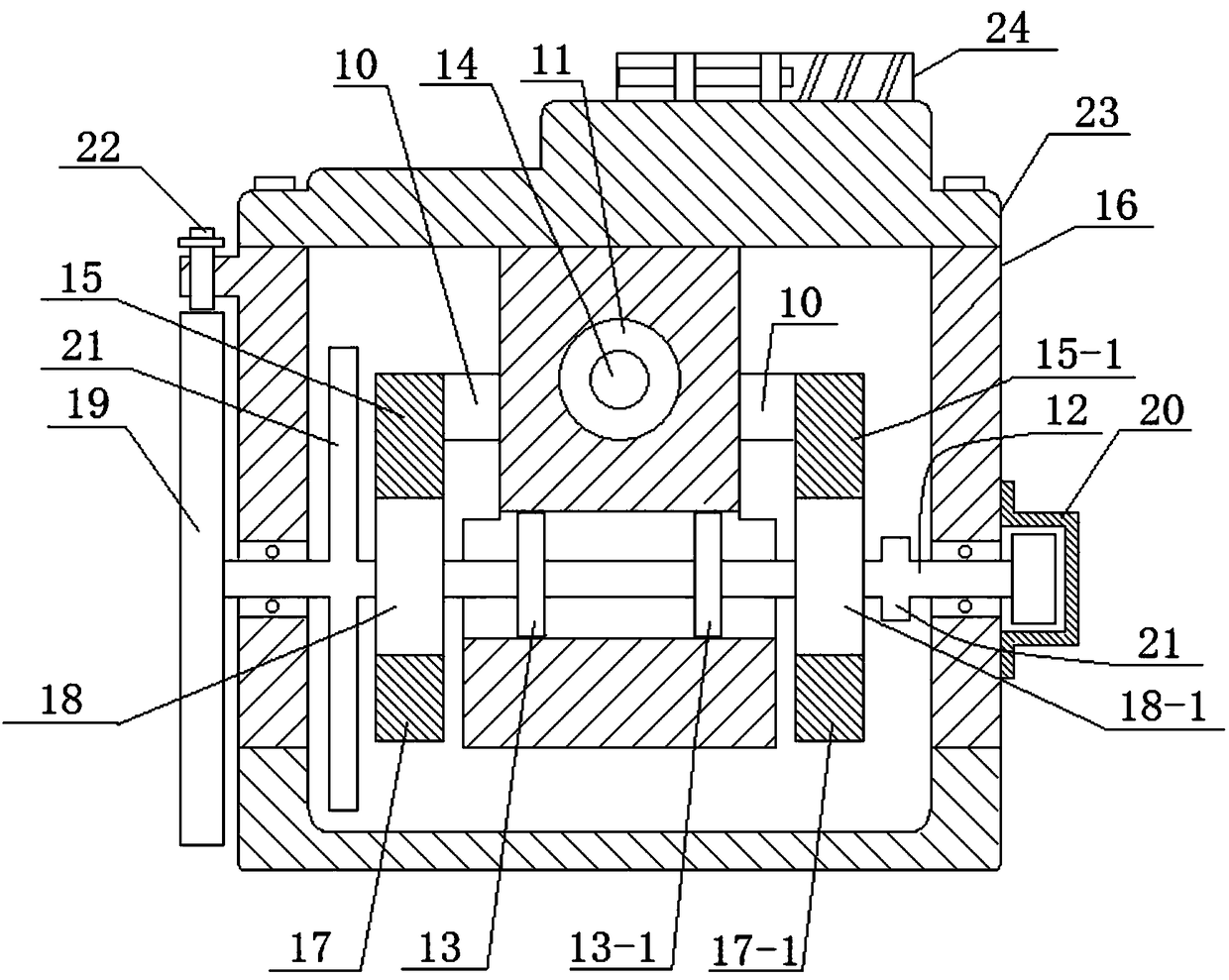

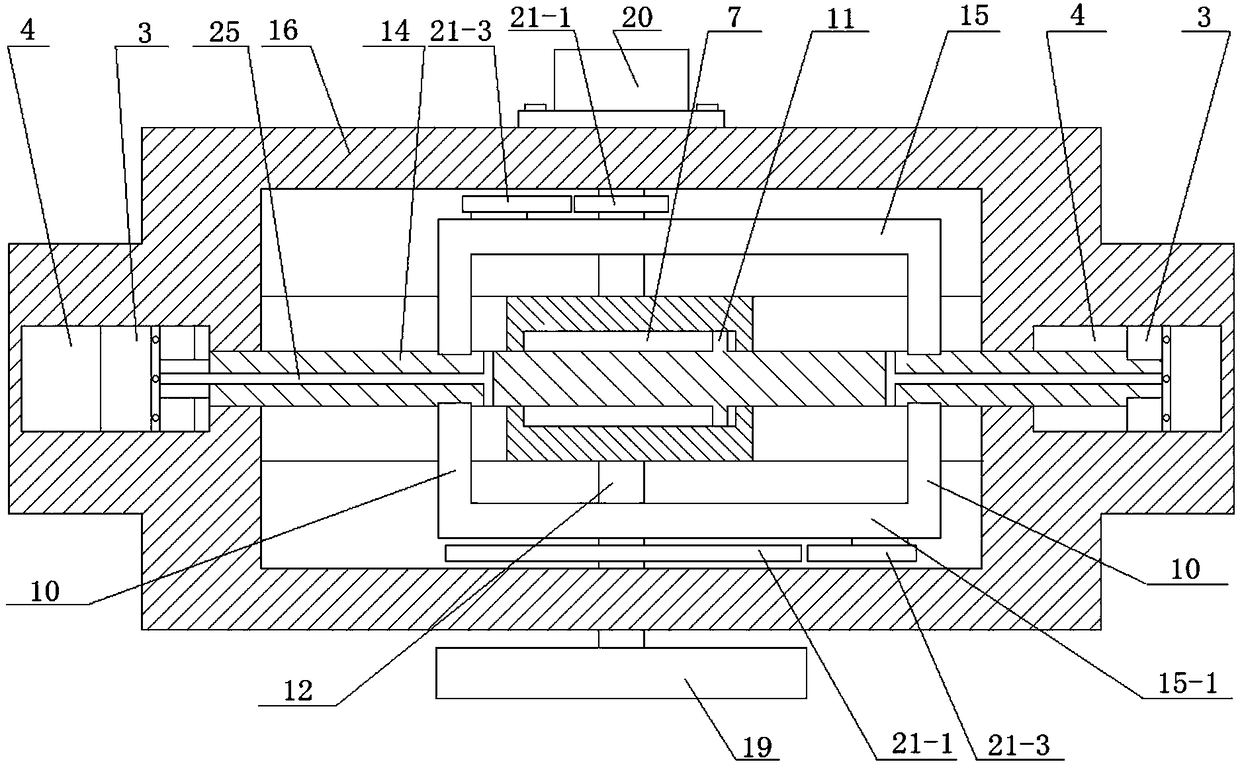

[0030] Such as figure 1 , figure 2 and image 3 As shown, the clean energy converter includes a cylinder system, a booster mechanism, a transitional balance wheel system 21, a timing system, and an intake and exhaust system. It is characterized in that: the cylinder system includes several cylinder groups, and the cylinder groups include two A symmetrically arranged cylinder, the cylinder includes a cylinder block 4, a piston 3, and a piston push rod 14, and the cylinder block 4 is provided with a main oil pressure port 5, a fuel nozzle 1 and a valve 8; the piston 3 passes through the piston push rod 14 is integrated with the piston 3 in another symmetrically arranged cylinder 4; the booster mechanism includes a booster cylinder 7 and a booster piston 11, and the booster cylinder 7 is provided with a booster oil pressure port 6, and the booster The booster piston 11 is affixed to the piston push rod 14 and is located in the booster cylinder 7; as Figure 6 As shown, the tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com