Pipeline pump having back-flushing function

A technology of backwashing and pipeline pump, which is applied to the components, pumps, pump devices, etc. of the pumping device for elastic fluid, which can solve the problem of air leakage of the pump body, easy blockage of the nozzle, poor sealing of the connection between the pump body and the pipeline, etc. problems, to prevent air leakage, easy to operate, and to maintain the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further explained below in conjunction with specific embodiments.

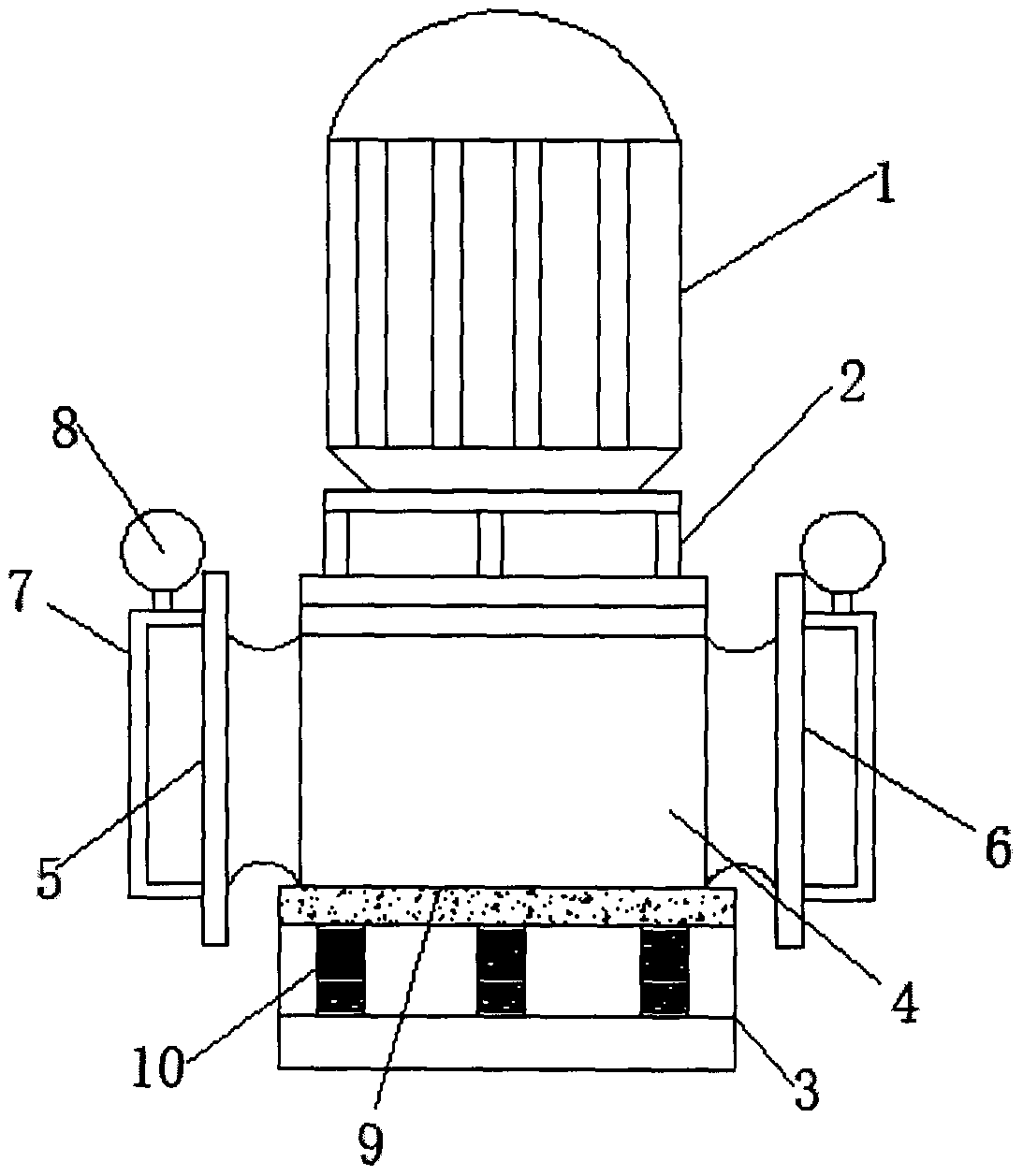

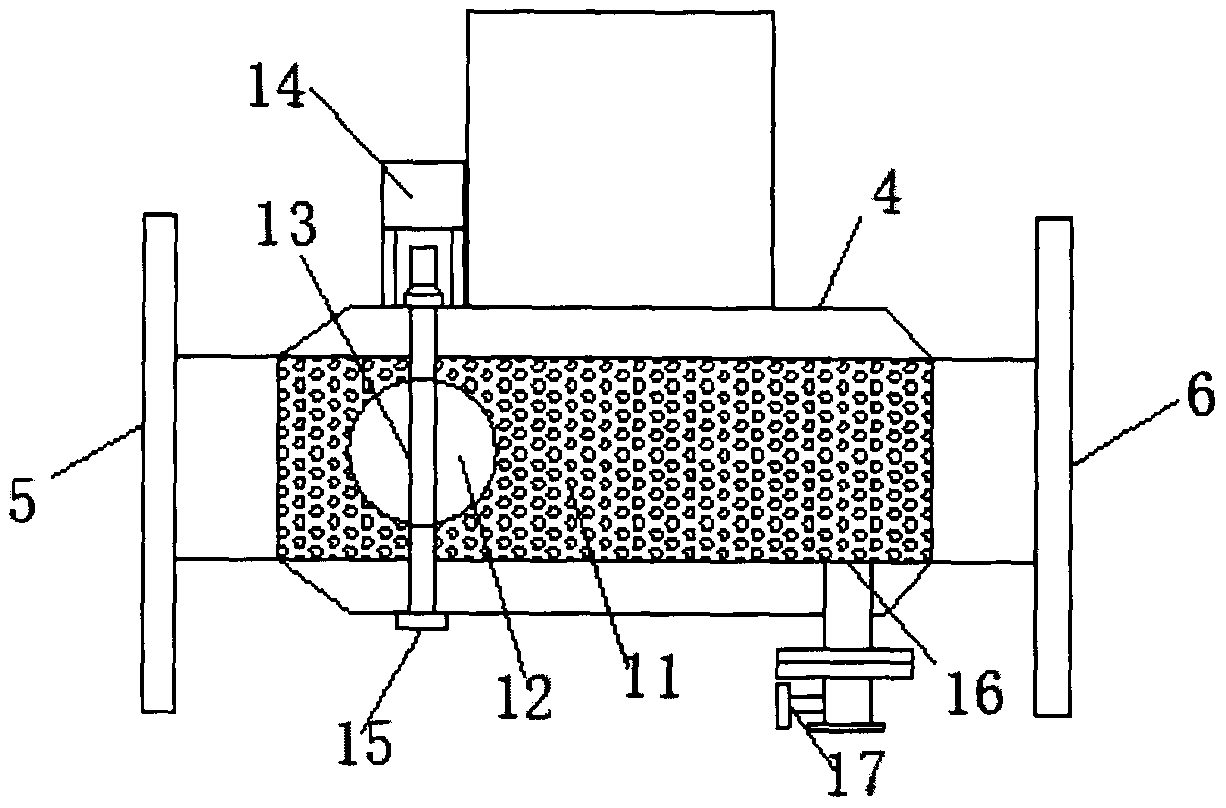

[0018] Such as Figure 1-2 As shown, a pipeline pump with backwash function includes a motor 1, a base 3, a pump body 4, a backwash filter cartridge 11, a stainless steel filter screen 12, a screw 13, an electric rotary valve 14, a guide post hole 15, and a sewage pipe 16 and an electric drain valve 17, the pump body 4 is located at the top of the base 3, and the motor 1 is located above the pump body 4, and a backwash filter cartridge 11 is provided inside the pump body 4, and A screw 13 is fixedly installed on the inner side wall of the backwash filter cartridge 11, a stainless steel filter screen 12 is provided on the outside of the screw 13, and an electric rotary valve 14 is fixedly installed at the top of the screw 13 It is arranged at the top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com