Far infrared electric heater reflecting plate structure and far infrared electric heater

A technology of reflectors and infrared electricity, applied in electric heating systems, central heating components, household heating, etc., can solve problems such as potential safety hazards, and achieve the effect of avoiding floor fires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

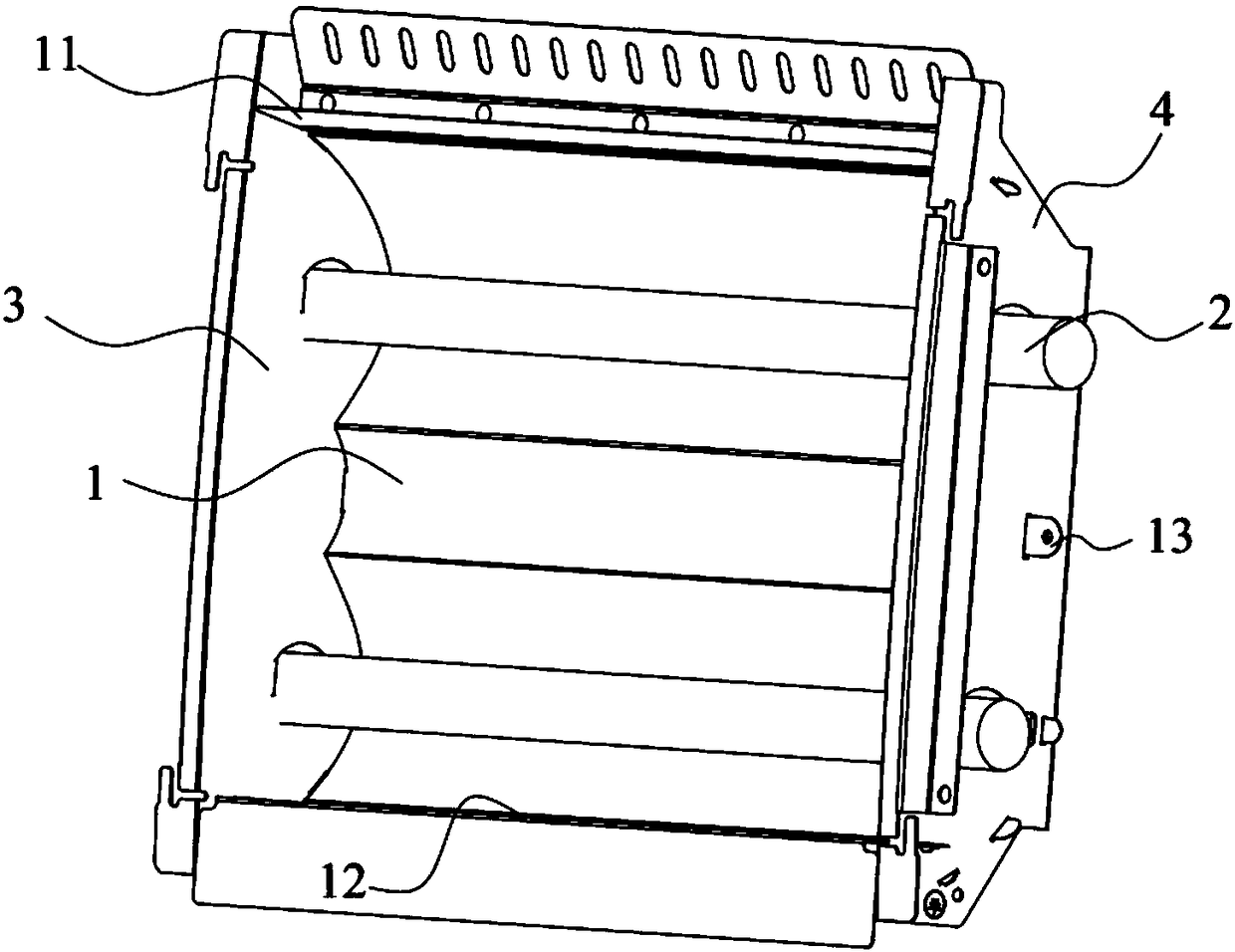

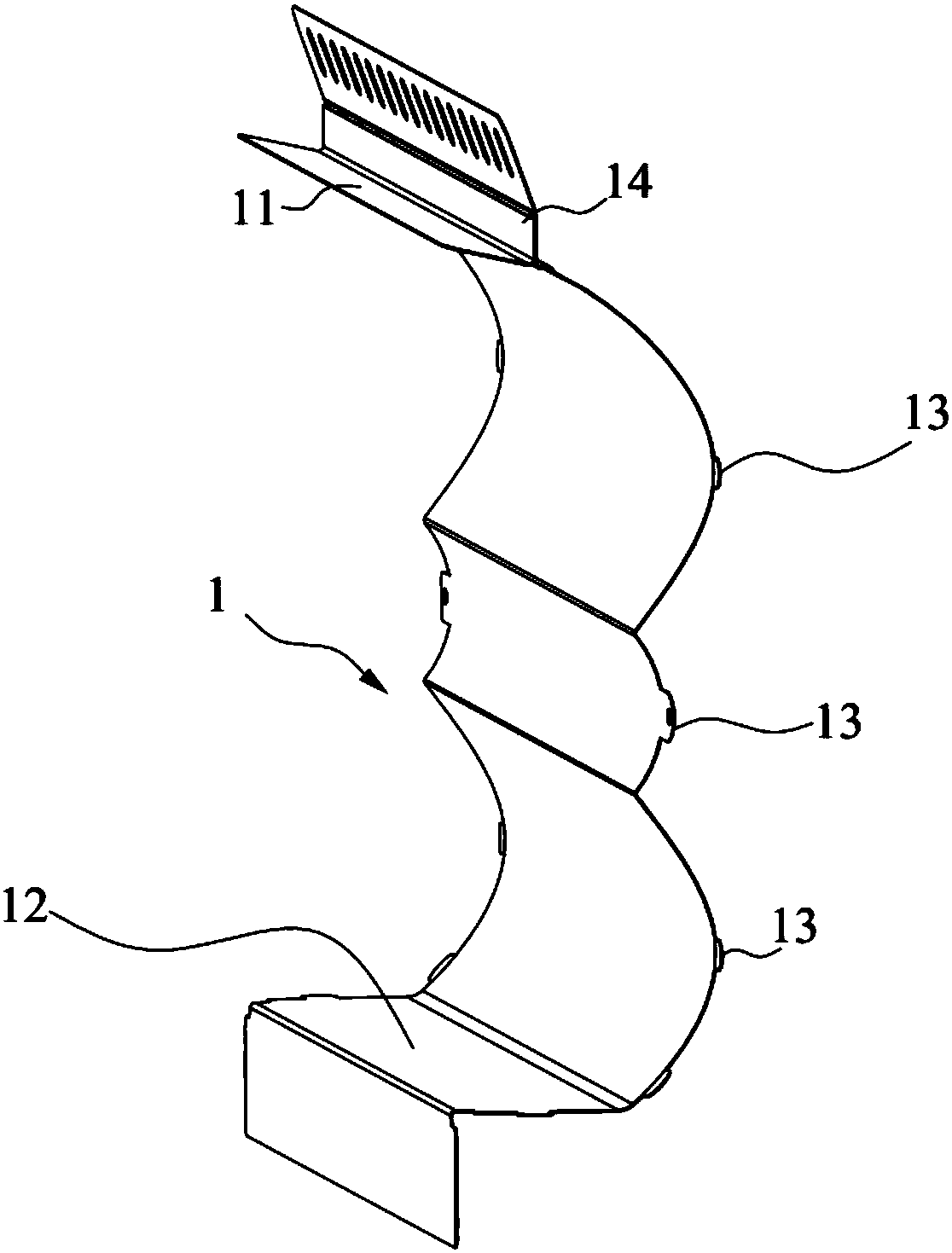

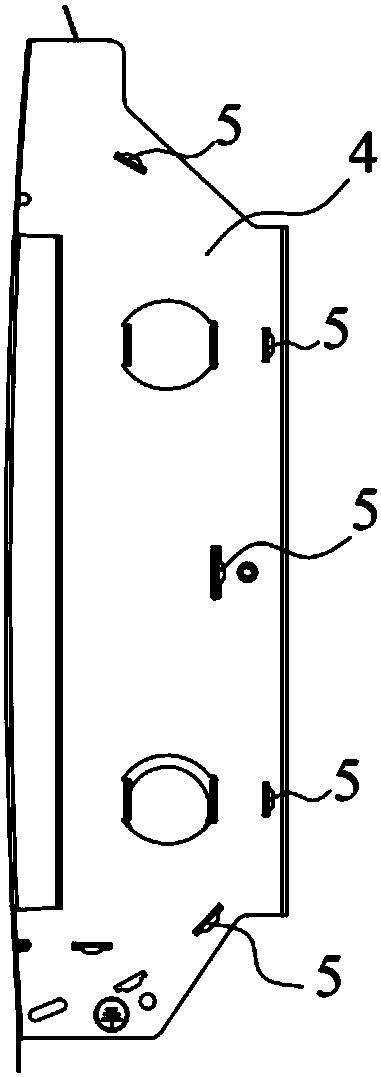

[0037] Such as figure 1 As shown, this embodiment provides a reflective plate structure for a far-infrared electric heater, and the reflective plate structure includes a reflective plate 1, a heat pipe 2, an upper baffle 11, a lower baffle 12, a left side plate 3 and a right side plate 4 . The reflection plate 1 is fixed between the left side plate 3 and the right side plate 4, and the surface where the reflection plate 1 is located is perpendicular to the left side plate 3 and the right side plate 4; The two ends of the heat pipe 2 are fixed on the left side plate 3 and the right side plate 4; the reflector 1 is an arc surface, and the heat emitted by the heat pipe 2 is reflected to the obliquely above, obliquely below and directly ahead of the reflector 1 through the reflector 1.

[0038] Such a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap