Electrode heating boiler

An electrode heating and electrode technology, which is applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of phase electrode heating and burning out, affecting the normal use of boilers, etc., to achieve increased heating power, stable and reliable work, The effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below by means of the accompanying drawings and examples.

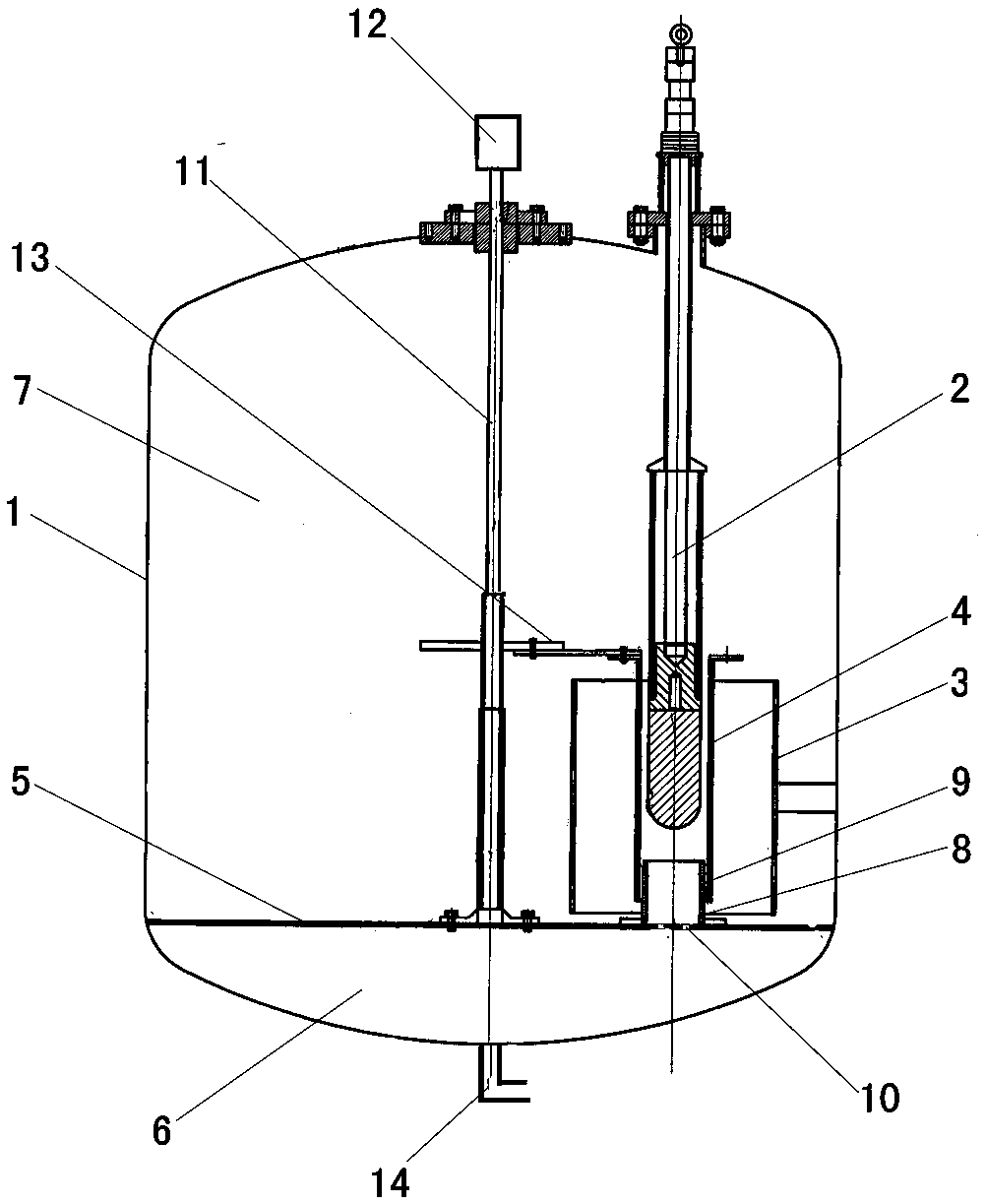

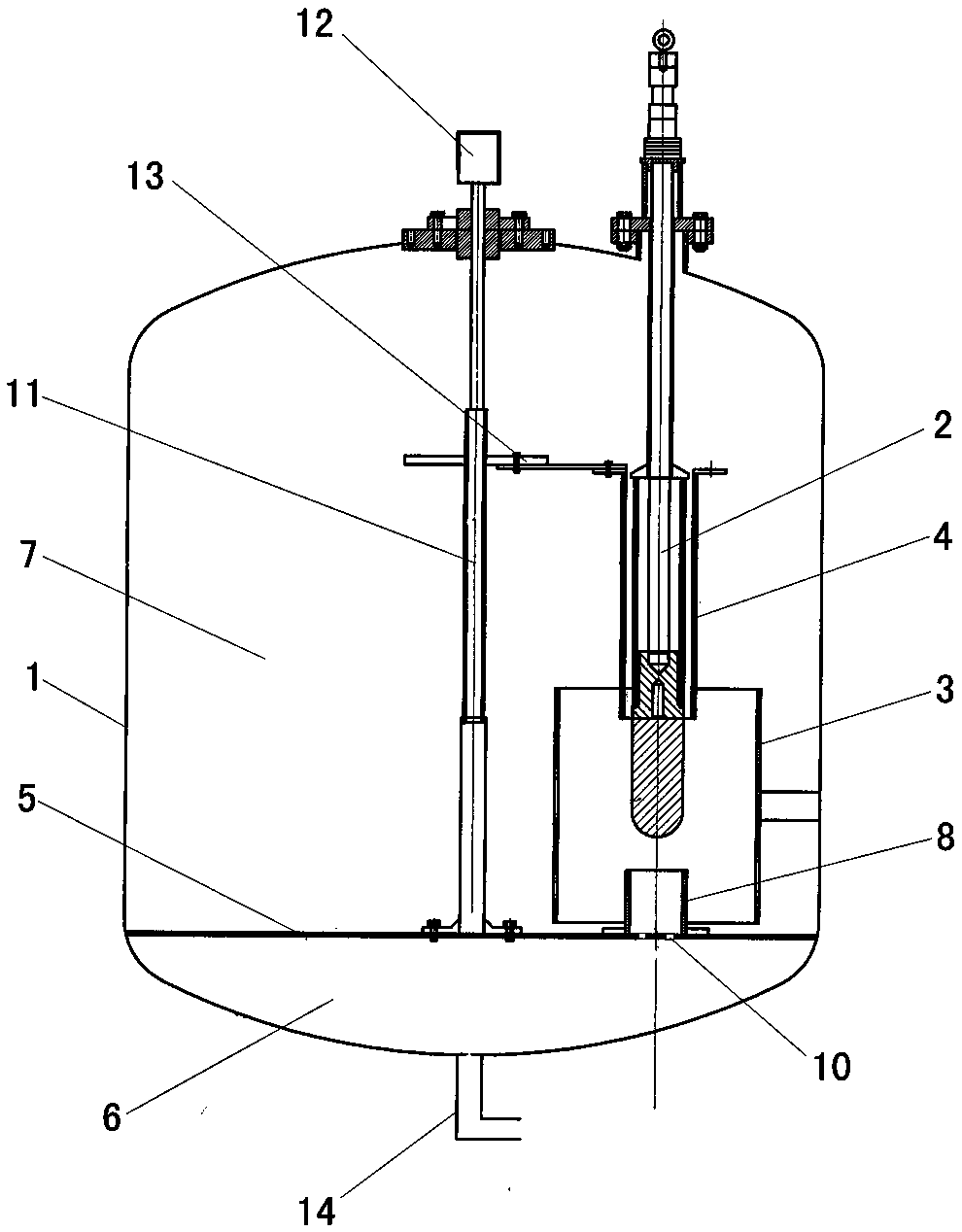

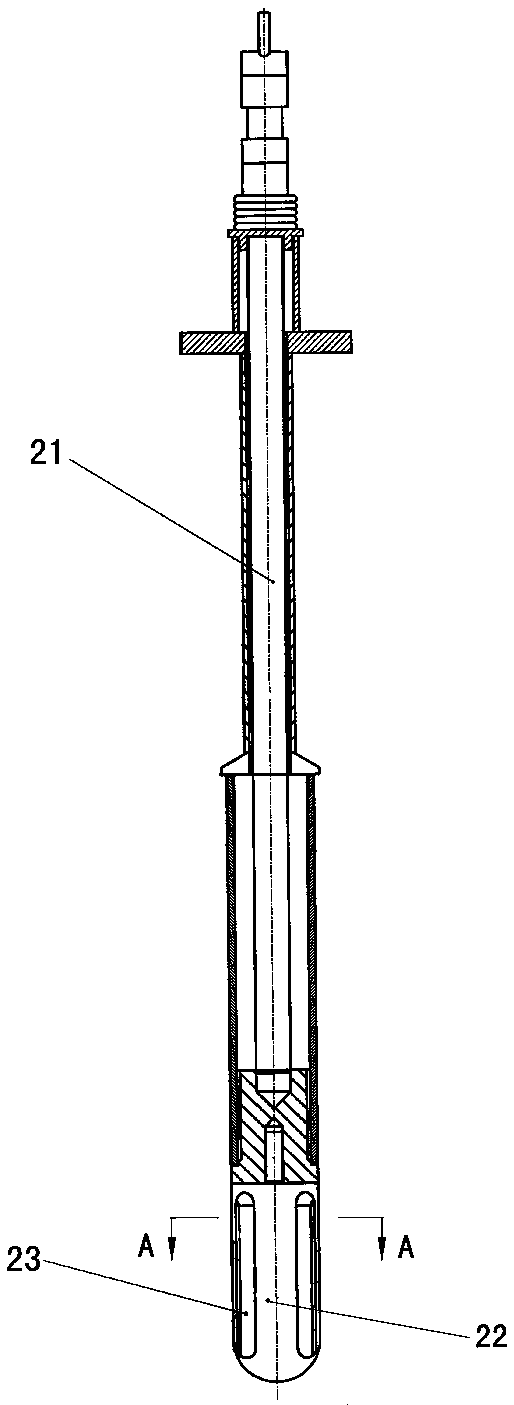

[0017] like figure 1 and figure 2 Shown: an electrode heating boiler, including a pot shell 1, and a phase electrode 2 and a zero electrode 3 arranged in the pot shell 1 and immersed in an electrolyte. The zero electrode 3 surrounds the periphery of the phase electrode 2 and forms a heating zone with the phase electrode 2 . An isolation shield 4 is arranged between the phase electrode 2 and the zero electrode 3, and the isolation shield 4 can move up and down along the axial direction of the phase electrode 2 under the action of the lifting mechanism. When the isolation shield 4 leaves the phase electrode 2 and moves upward, the phase electrode 2 is fully exposed to the inter-electrode electrolyte (water). At this time, the ion migration in the inter-electrode electrolyte increases, which increases the heating power of the boiler. When the isolation shield 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com