Surface defect detection device and detection method for high-precision optical element

A technology of optical components and detection devices, which is applied in the field of optical detection, can solve problems such as low detection accuracy, limited practicability, and slow detection speed, and achieve the effects of improving detection efficiency, extending depth of field, and reducing optical resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

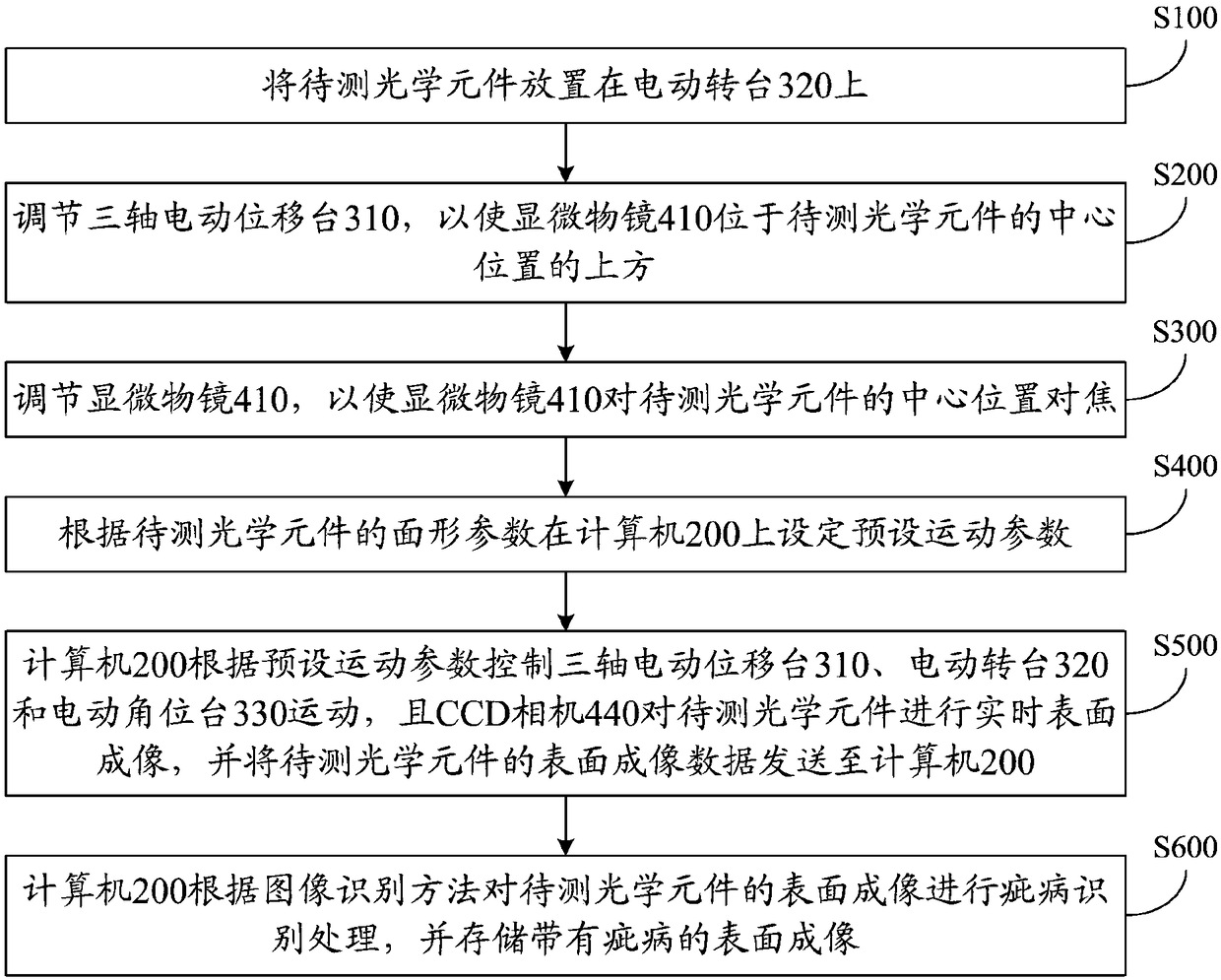

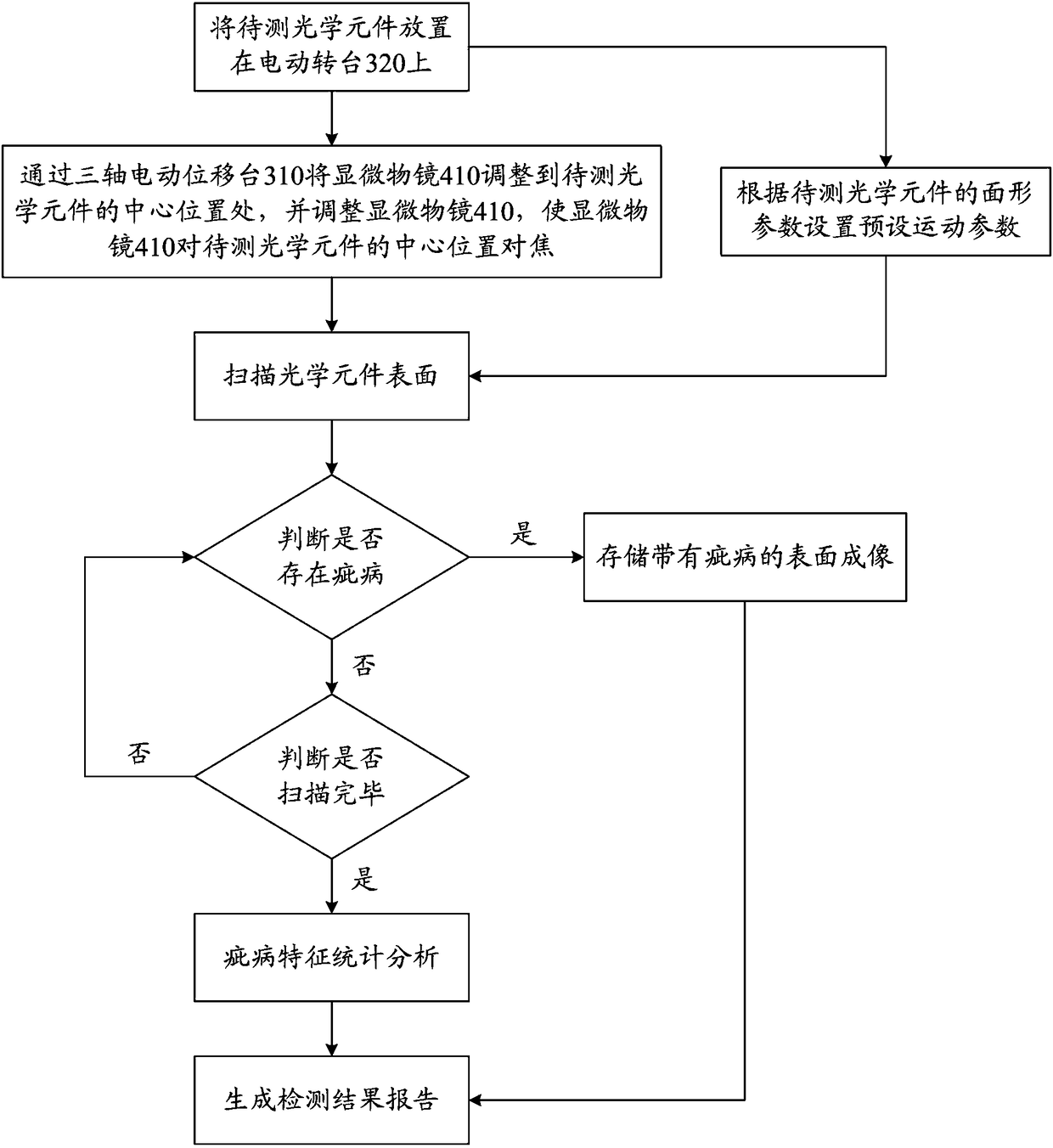

[0056] As a specific implementation, the method for detecting surface defects of high-precision optical components also includes the following steps:

[0057] The computer 200 performs a statistical analysis of defect characteristics on all stored surface images with defects, and generates a test result report, which includes the defect type of the optical element to be tested, the number corresponding to each defect type, and the total number of defects head.

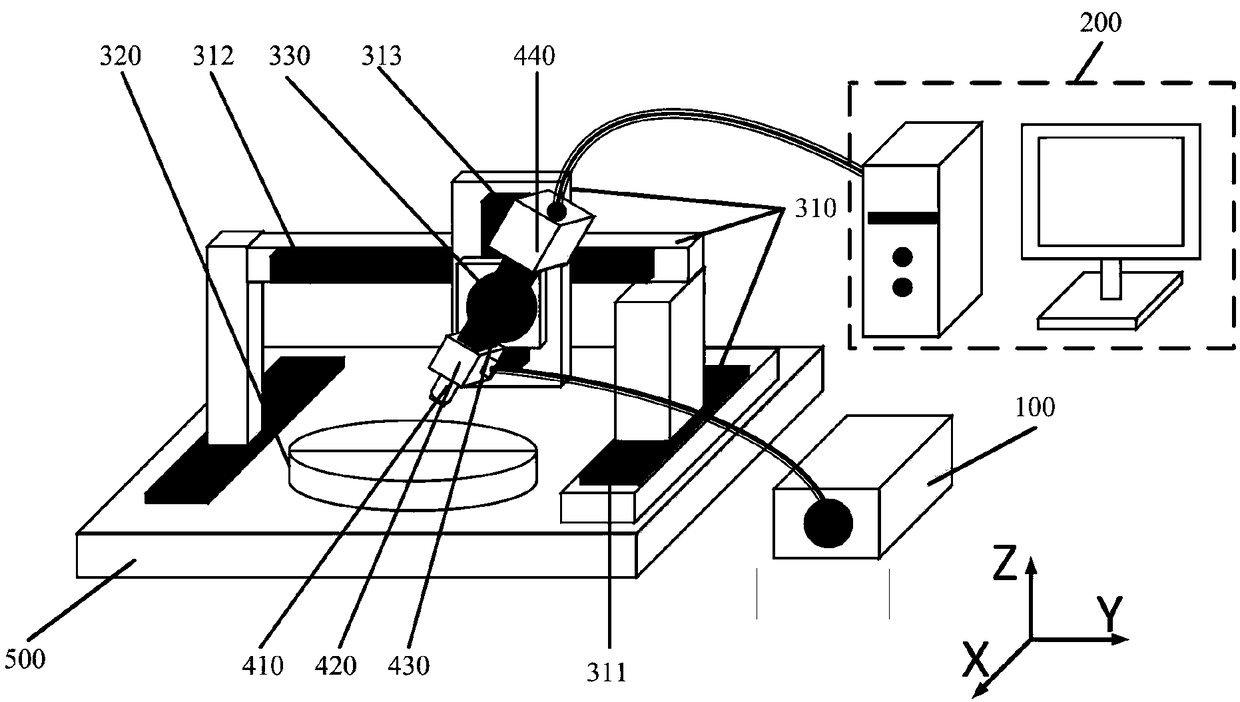

[0058] In this embodiment, if image 3 As shown, the optical element to be tested is placed on the electric turntable 320, and the microscope objective lens 410 is adjusted to the optical position to be tested through the three-axis electric translation stage 310 (mainly through the X-axis electric translation stage 311 and the Y-axis electric translation stage 312). At the center position of the component, adjust the three-axis electric translation stage 310 (mainly the Z-axis electric translation stage 313) and adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com