An efficient bag dust collector

A dust-removing device and high-efficiency technology, applied in the fields of combination devices, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of difficulty in cleaning, discount of dust-removal efficiency, easy-to-adhesion of dust to dust collectors, etc., and achieve high dust-removal efficiency and dust-removal effect. Good, reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

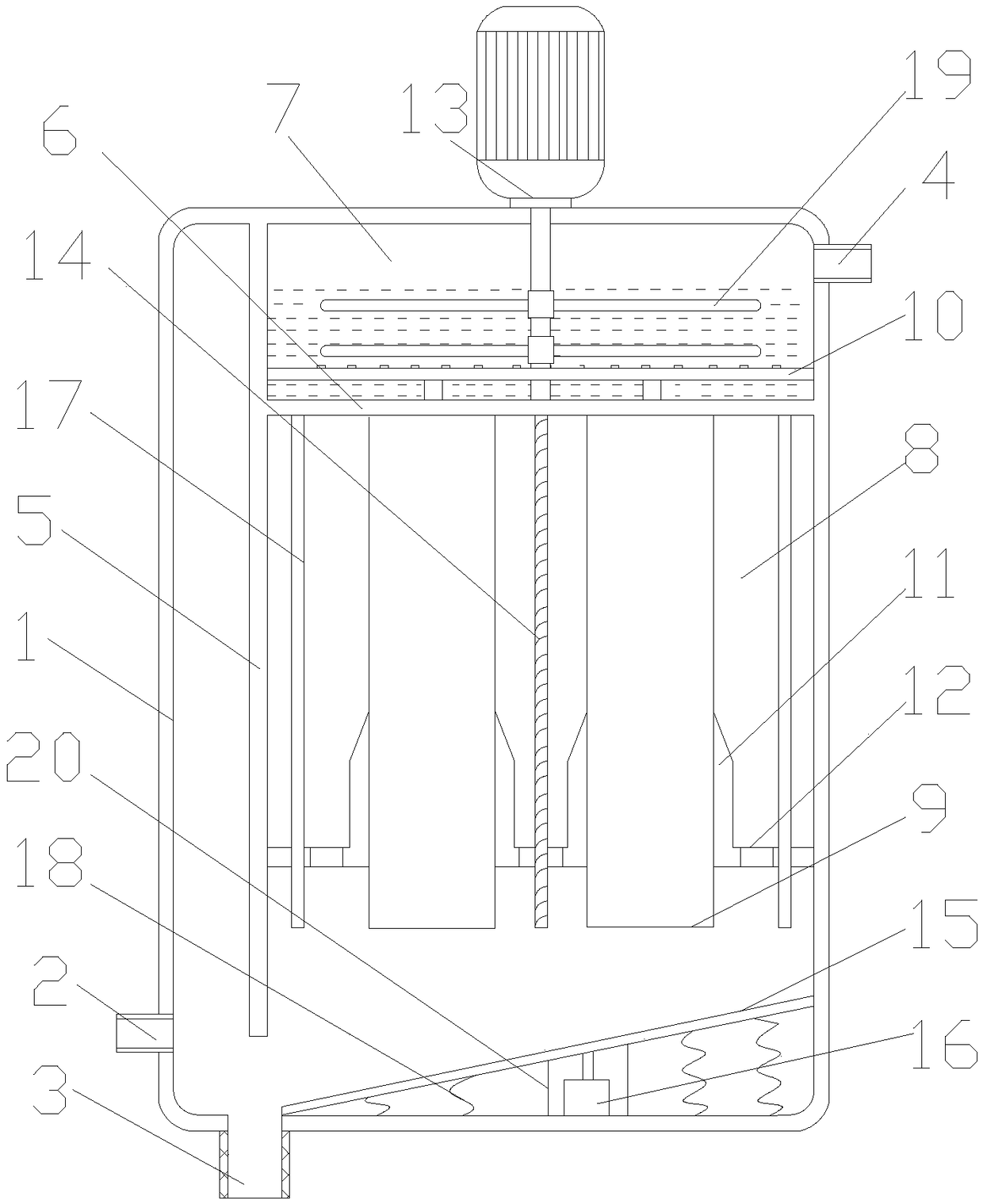

[0016] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a bag-type high-efficiency dust removal device proposed by the present invention.

[0017] refer to figure 1 , a high-efficiency bag dust removal device proposed by the present invention includes a housing, the bottom of one side of the housing 1 is provided with a dust-containing gas inlet 2 and a dust outlet 3, and the top of the other side is provided with a purified gas outlet 4. A dust shield 5 is provided on the side of the housing 1 close to the dust-laden gas inlet 2. The dust shield 5 is arranged vertically along the height direction of the housing 1 and is located above the dust outlet 3, which faces away from the dust-laden gas inlet 2. One side is provided with a partition plate 6, the top of the partition plate 6 is a clean room 7, and the bottom is a treatment room 8, and a number of filter bags 9 are arranged in the treatment room 8, and the filter bags 9 pass through the condui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com