Battery cell drying gas device, battery cell drying gas system, and preparation method of battery cell drying gas

A dry gas and battery technology, applied in the direction of dry gas arrangement, separation method, chemical instrument and method, etc., can solve problems such as inconvenient transportation, unstable gas supply pressure, affecting product quality, etc., to avoid production stoppage or product quality Problems, stable air supply pressure, and avoiding insufficient air supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

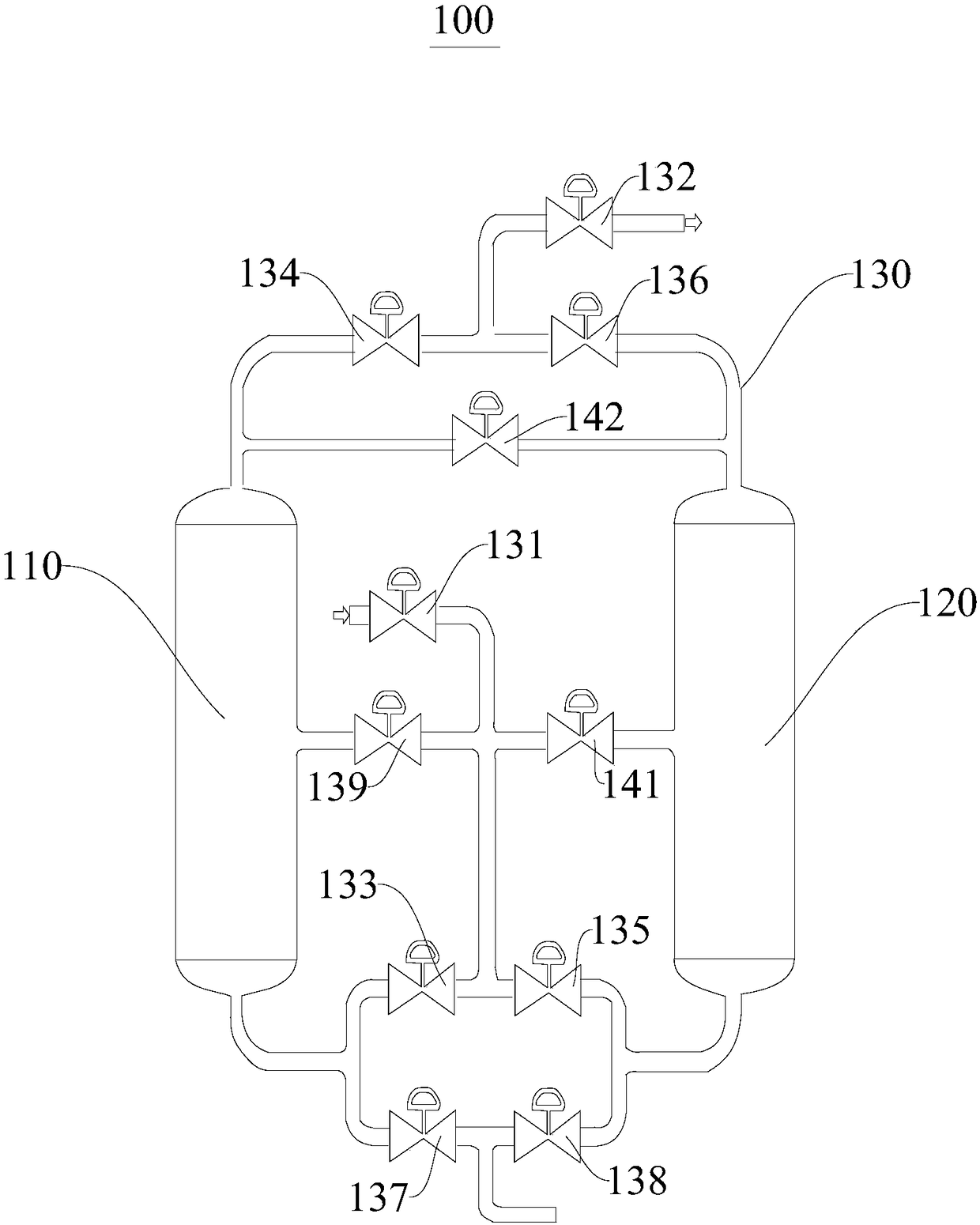

[0031] The cell drying gas device 100 includes a first adsorption tower 110 and a second adsorption tower 120 and a pipeline 130 connecting the first adsorption tower 110 and the second adsorption tower 120 . Mainly through the operation of the valve set on the pipeline 130, the gas in the first adsorption tower 110 and the gas in the second adsorption tower 120 are dried, and provided to the battery for drying the battery. Core drying device, so that the production line can continuously provide dry gas to the battery cells, without the need to replace the filled dry gas, so that the air supply pressure is more stable, and the gas can be supplied in time to avoid the shutdown of the battery cells due to insufficient dry gas supply Or product quality problems, improve the production efficiency of batteries.

[0032] In this embodiment, a desiccant is provided inside the first adsorption tower 110 and the second adsorption tower 120 to dry the gas, and the desiccant cannot react...

Embodiment 2

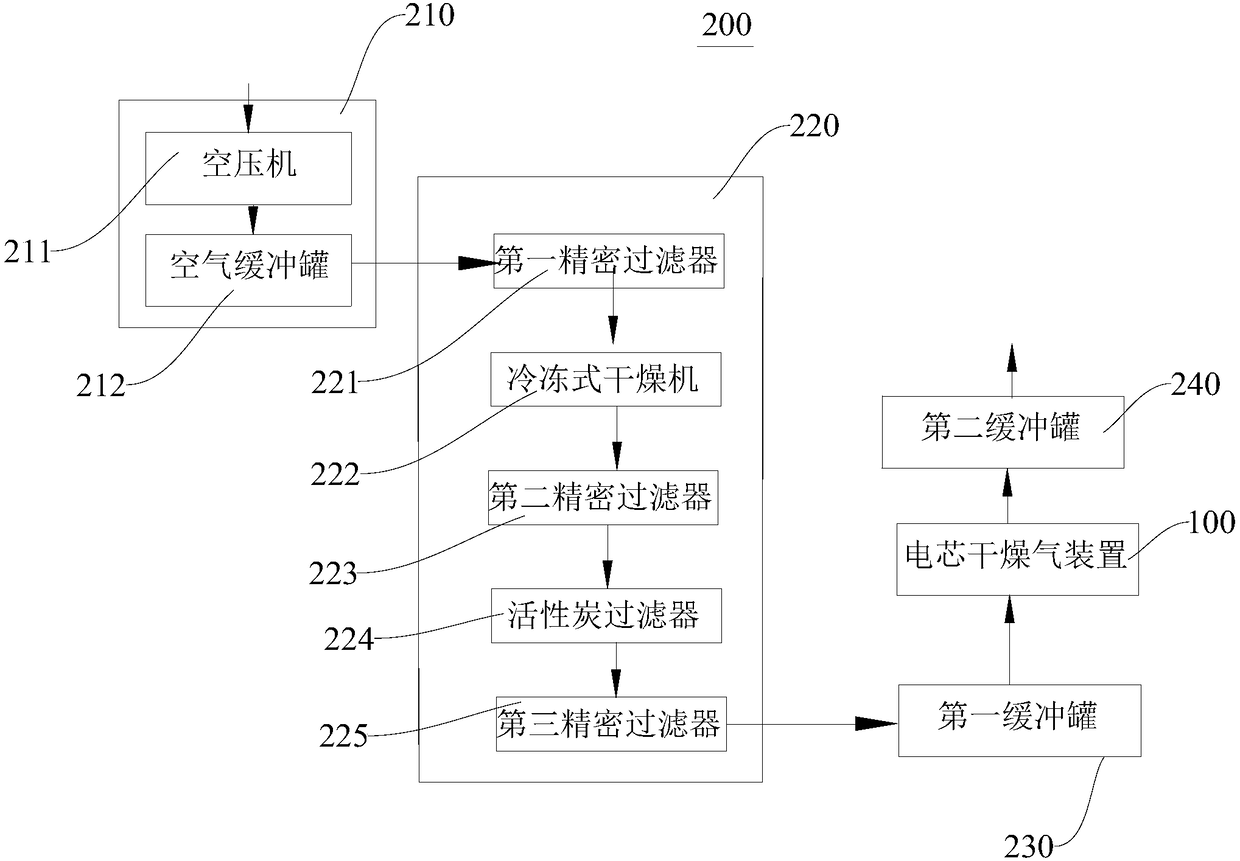

[0041] This embodiment provides a cell drying gas system 200, including an air compression system 210, a purification system 220, a first buffer tank 230, and the cell drying gas device 100 provided in Embodiment 1. The air outlet of the air compression system 210 is connected to the The inlet port of the purification system 220 is connected, the gas outlet port of the purification system 220 is connected with the inlet port of the first buffer tank 230, the gas outlet port of the first buffer tank 230 is connected with the pipeline 130 at the first valve 131, and the second valve The cell drying gas at the gas outlet at 132 is used for cell drying.

[0042] Compress the air through the air pressure system 210 first, then purify the air through the purification system 220, and use the first buffer tank 230 to temporarily store it, and then pass it into the cell drying gas device 100 for drying, and finally obtain the cell drying gas Used for cell drying.

[0043] In this embo...

Embodiment 3

[0049] This embodiment provides a method for preparing cell drying gas, using the cell drying gas device 100 provided in Embodiment 1. Including the following steps:

[0050] (1), first open the first valve 131, the third valve 133, the fourth valve 134 and the second valve 132, so that the first valve 131, the third valve 133, the first adsorption tower 110, the fourth valve 134, the second The valves 132 are connected in turn to form the first intake path; (2), then open the first valve 131, the fifth valve 135, the sixth valve 136 and the fourth valve 134, the first valve 131, the fifth valve 135, the second adsorption Tower 120, the sixth valve 136, the fourth valve 134, and the first adsorption tower 110 are connected in sequence to form the first pressure equalization path; (3), then open the first valve 131, the fifth valve 135, the sixth valve 136 and the second The valve 132 makes the first valve 131, the fifth valve 135, the second adsorption tower 120, the sixth va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com