Test tube cleaning machine

A technology for cleaning machines and test tubes, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of inability to clean the test tubes, puncture, and the inability of the brush tube to extend into the test tube.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below through specific embodiments:

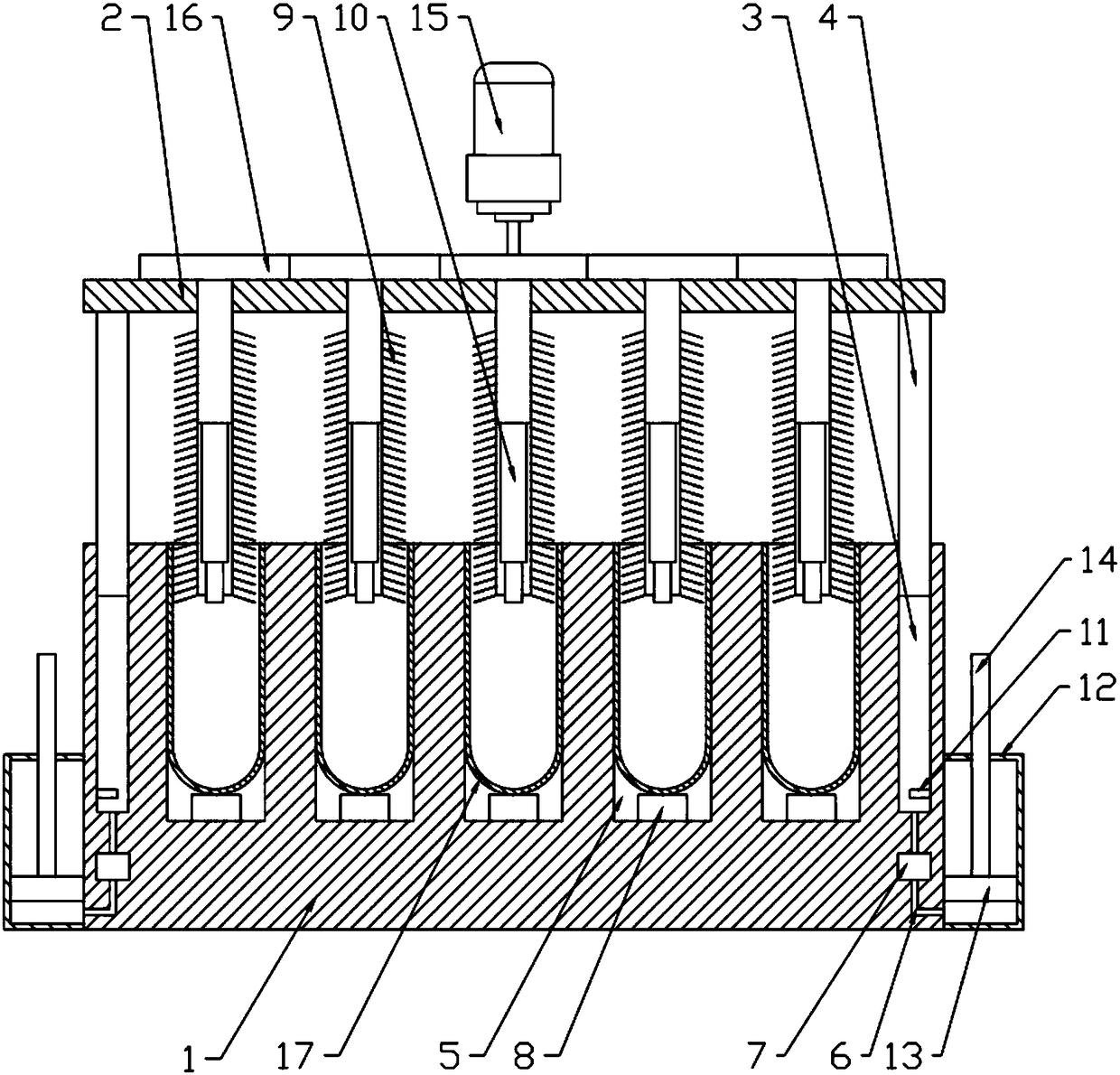

[0015] The reference signs in the drawings of the specification include: box body 1, cover plate 2, support hole 3, support column 4, receiving hole 5, drain hole 6, solenoid valve 7, electric switch 8, cleaning brush 9, telescopic rod 10 , Travel switch 11, recovery box 12, piston 13, push rod 14, motor 15, driven gear 16, test tube 17.

[0016] The embodiment of the test tube cleaning machine is basically as attached figure 1 Shown: It includes a power supply, a box body 1 and a cover plate 2 that covers the upper part of the box body 1. The four corners of the box body 1 are respectively provided with a supporting hole 3, and the box body 1 is also arrayed with 5×5 to be accommodated. The accommodating hole 5, the supporting hole 3 and the accommodating hole 5 of the cleaning test tube 17 are all vertically arranged blind holes. The supporting column 4 is slidably connected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com