Inner spinning equipment

A technology of internal spinning and equipment, applied in the direction of metal processing equipment, feeding devices, positioning devices, etc., can solve the problem of low production efficiency, not suitable for mass production, and unable to meet the low cost, high efficiency, high precision, high Quality and other issues, to achieve the effects of high production efficiency, increased rigidity, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

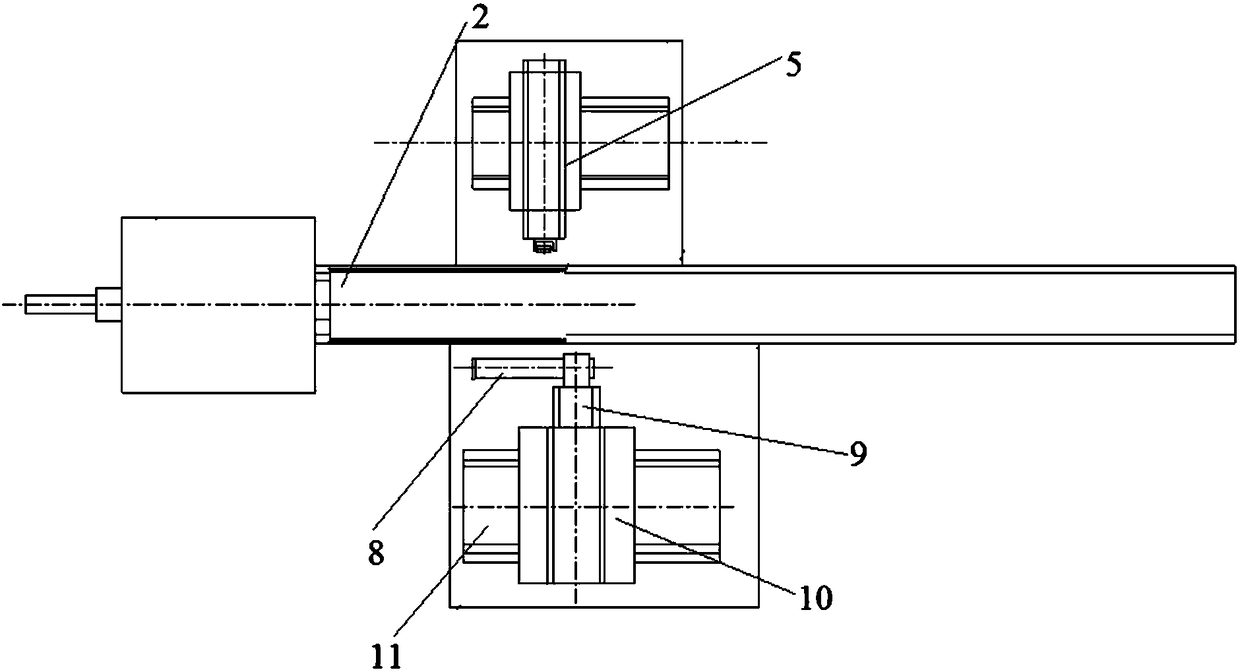

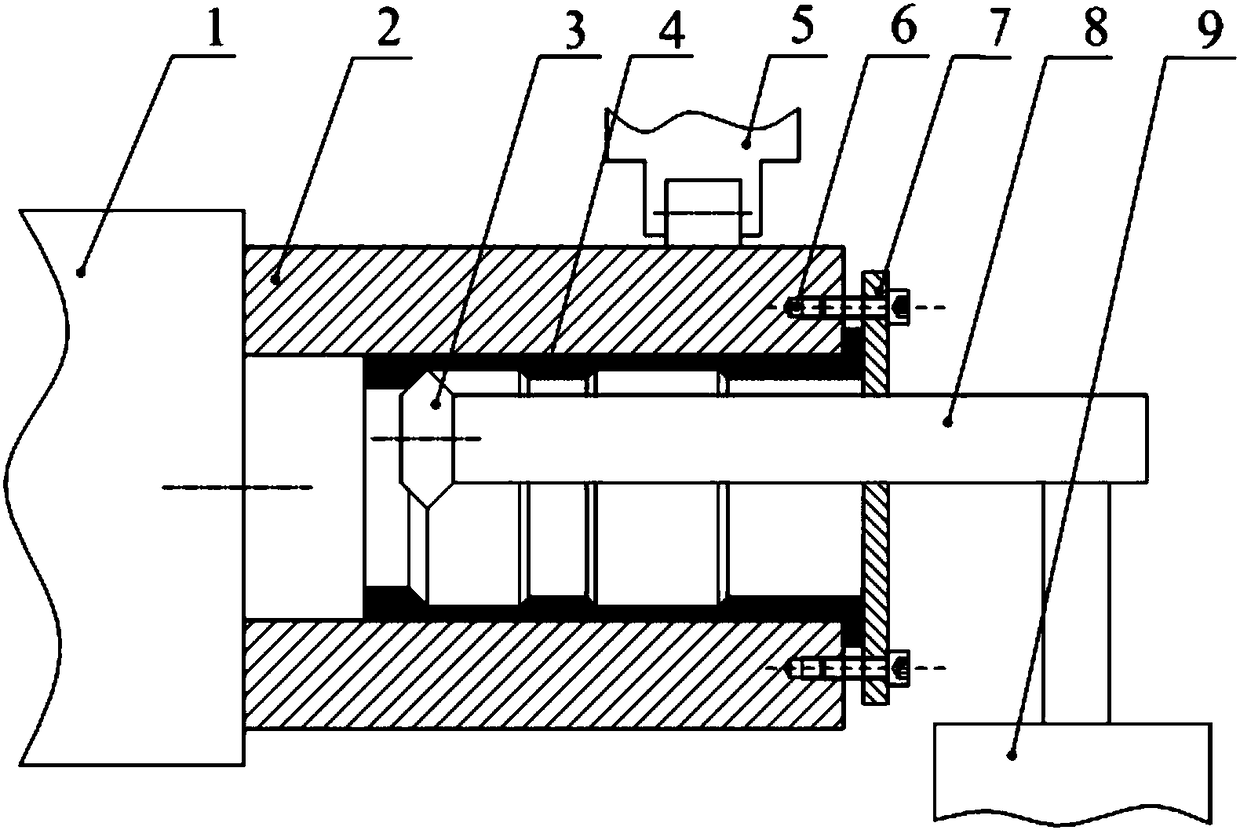

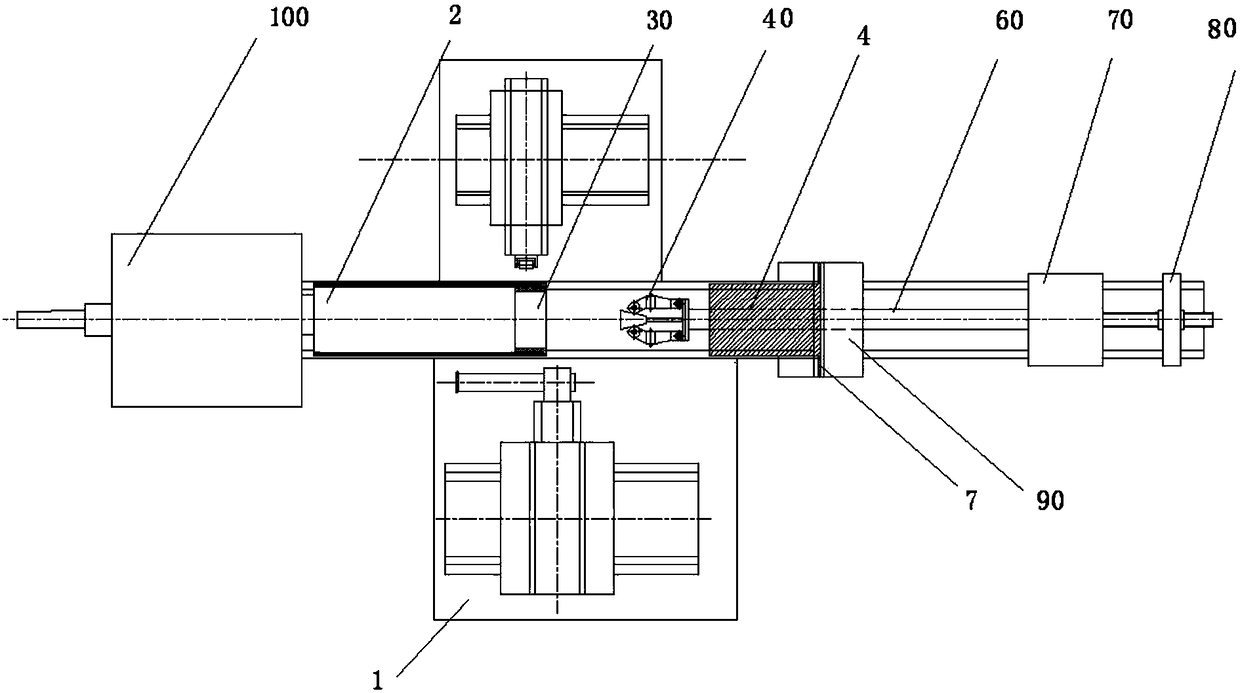

[0025] See Figure 1-2 , The embodiment of the present invention provides an internal spinning equipment, which includes: a spinning machine bed 1, a core mold 2, an internal spinning assembly having a spinning wheel 3, a first spinning wheel arm 8 and a lateral carriage 9 , The longitudinal feed mechanism 10, the transverse feed mechanism 11, the balance wheel mechanism 5 and the pressing ring 7 of the internal spinning assembly.

[0026] Specifically, the spinning machine bed 1 is used to provide support. One end of the core mold 2 is connected with the spindle of the spinning machine tool to rotate under the drive of the spindle. One end of the blank 4 is placed in the cavity of the core mold 2, and the other end is pressed against the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com