Automatic heating and frying device for aluminum sheet

A heating control device and technology for aluminum sheets, applied in the field of machinery, can solve the problems of easy damping of aluminum sheets, influence of processes, insufficient lubrication of aluminum sheets, etc., and achieve the effects of saving manpower and time, high degree of automation, and simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

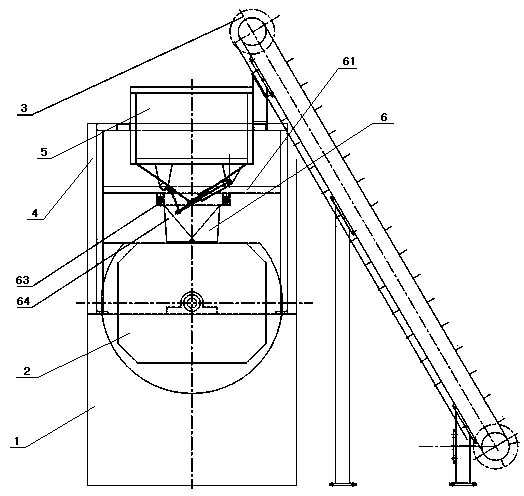

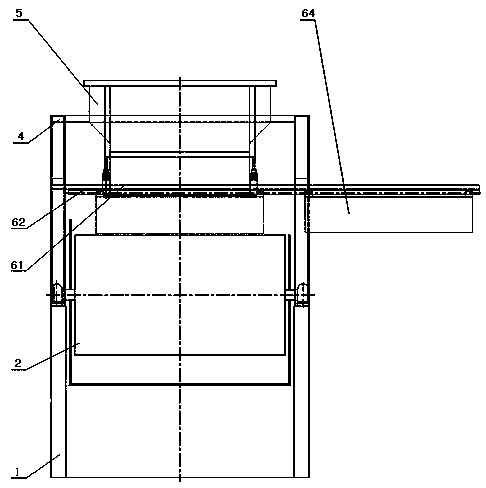

[0022] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

[0023] see in conjunction Figure 1-Figure 3 As shown, the embodiment of the present invention provides an automatic heating and frying device for aluminum flakes, including a frame 1, a frying machine 2 installed on the frame 1, a conveying table 3, a hopper mounting frame 4, and a hopper mounting frame 4. The heating bucket 5 on the frame 4;

[0024] The hopper mounting frame 4 is a cube structure frame installed on the top of the frame 1, and the heating bucket 5 is installed on the top of the hopper mounting frame 4;

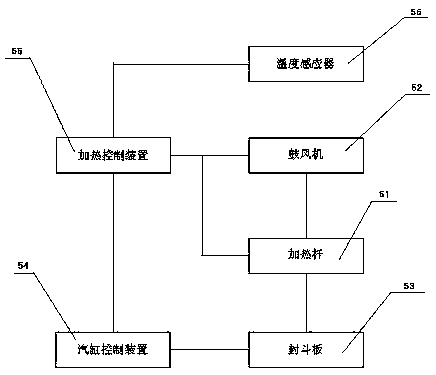

[0025] The heating bucket 5 includes: a heating rod 51 and a blower 52 for drying aluminum sheets, a bucket sealing plate 53 located at the bottom of the heating bucket, and a cylinder control device 54 for controlling the opening and closing of the bucket sealing plate 53. above the entrance of machine 2;

[0026] The conveying tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com