A cutting and grinding machine

A technology of a grinding machine and a clamping mechanism, applied in the field of auto parts processing, can solve the problems of increasing processing costs, high difficulty in cutting small parts, affecting processing efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

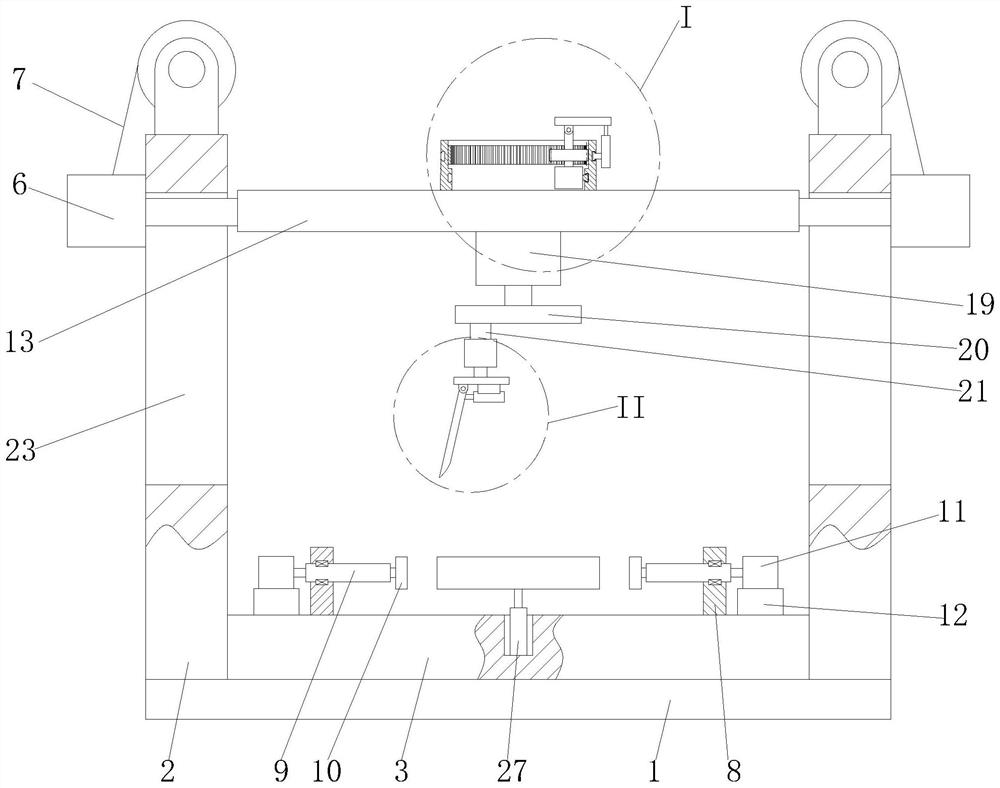

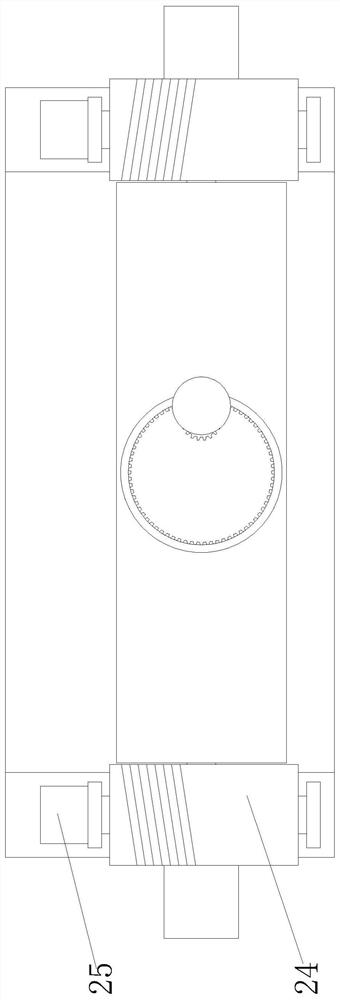

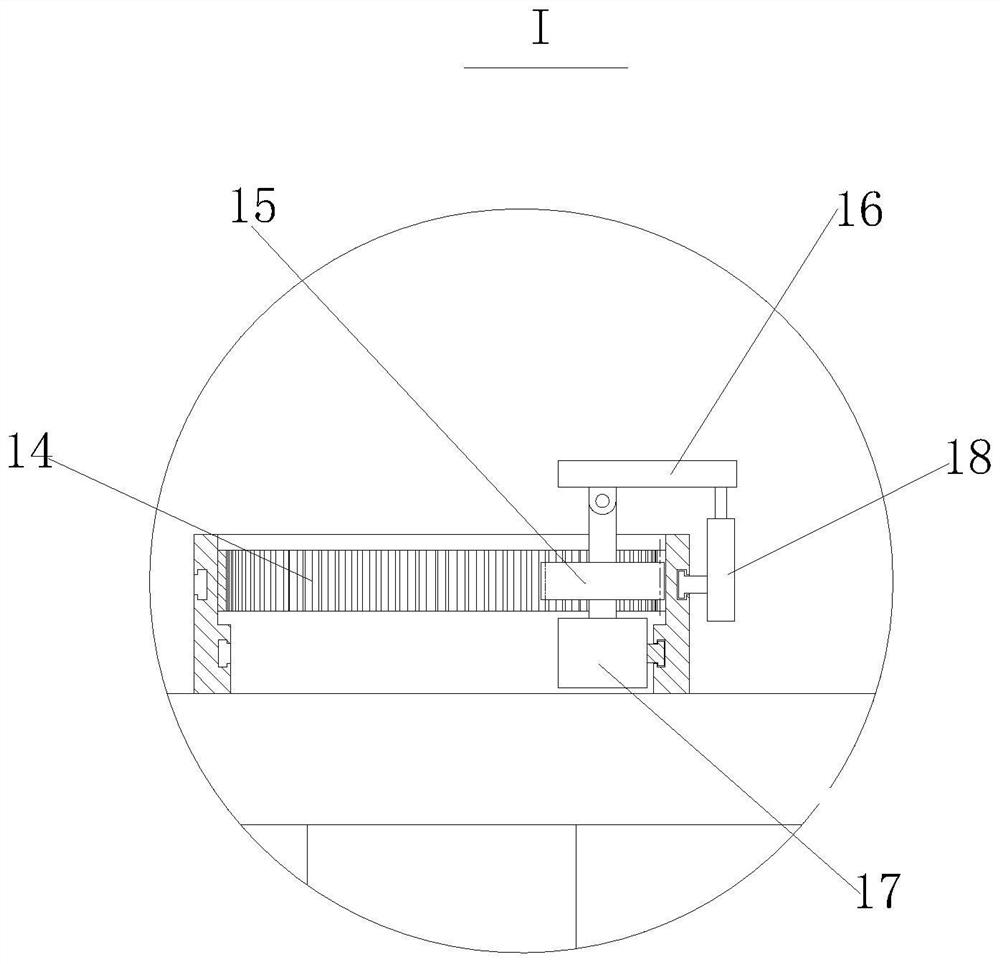

[0020] Such as Figure 1 to Figure 4 As shown, a cutting and grinding machine includes a base 1 and a shelf 2 arranged on the base 1. The base 1 is provided with a rotating device for placing workpieces and rotating the workpieces; the shelf 2 is provided with two One, a processing device for cutting and grinding the workpiece is provided between the two shelves 2, and a position adjustment device for turning and lifting the processing device is provided on the two shelves 2.

[0021] The rotating device is arranged on the base 1 for placing and rotating the workpiece; the processing device is arranged between two shelves 2 for cutting and grinding the workpiece; the position adjusting device It is set on two shelves 2 to provide turning and lifting for the processing device.

[0022]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com