A diamond wire cut crystalline silicon production line and its water system

A technology for diamond wire cutting and water production, which is used in manufacturing tools, stone processing equipment, work accessories, etc., can solve the problems of fluctuations in water supply quality, large peaks in drainage and water consumption, and long time consumption, so as to reduce water consumption and wastewater discharge. , the effect of reducing the rated capacity and avoiding the peak water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

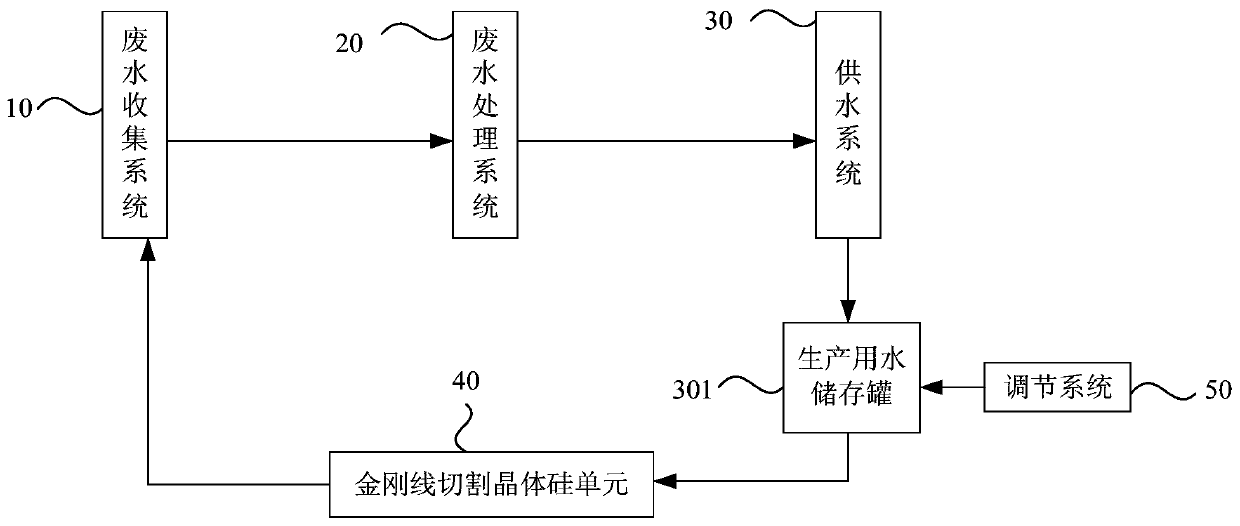

[0048] A diamond wire cutting crystalline silicon production line, the schematic structure is as follows figure 1 , including:

[0049](i) diamond wire cutting crystalline silicon unit 40, which includes at least one cutting machine, which has a cutting unit for cutting crystalline silicon, and also includes a water storage tank for storing circulating water; cutting crystalline silicon at the cutting unit During the process, the circulating water rinses the cutting seam; after the crystal silicon is cut, the circulating water continues to rinse to clean the cutting unit;

[0050] (ii) waste water collection system 10, said waste water collection system has at least one water inlet, is connected with the waste water outlet of the wire cutting machine of diamond wire cutting crystalline silicon unit 40, and the waste water that wire cutting machine produces is collected and enters the waste water collection system;

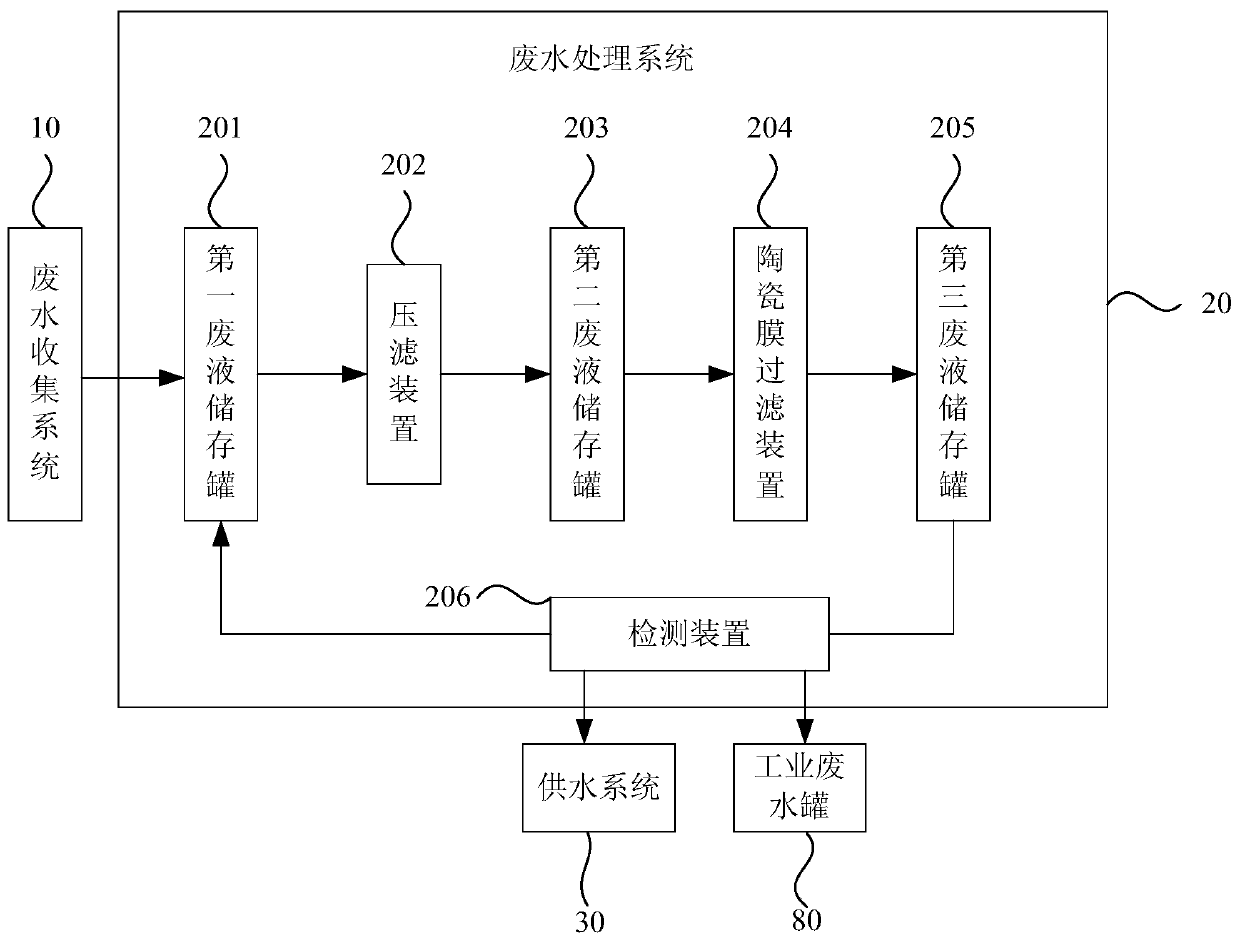

[0051] (iii) waste water treatment system 20, comprising the...

Embodiment 2

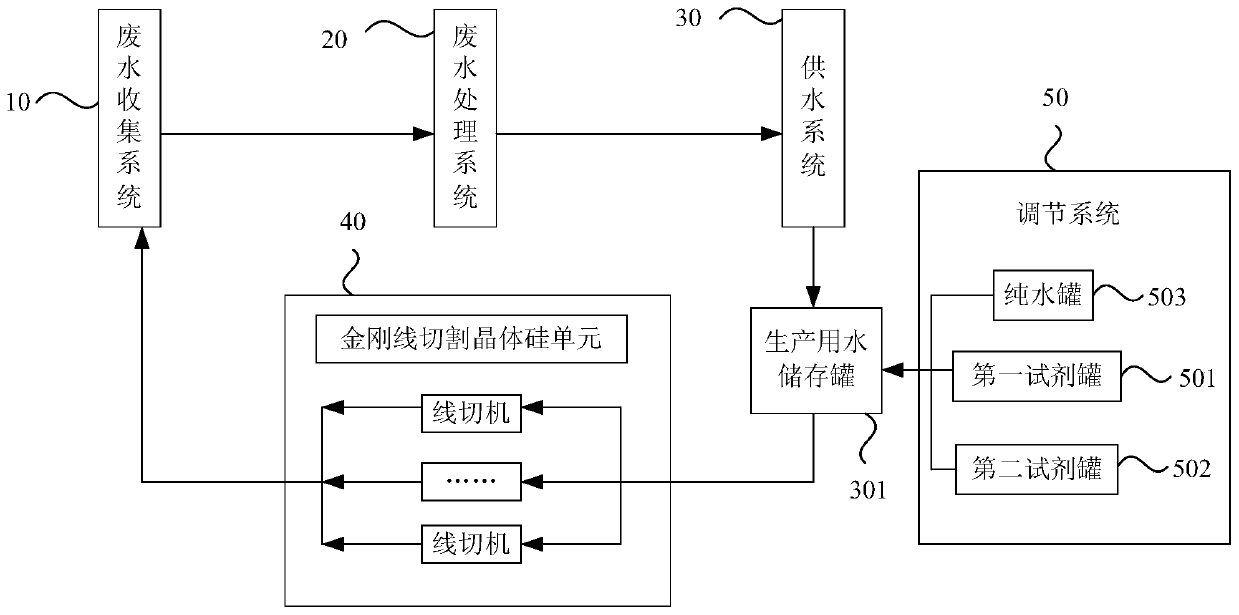

[0066] A diamond wire cutting crystalline silicon production line, the schematic structure is as follows image 3 , including:

[0067] A diamond wire cutting unit 40 consisting of at least one wire cutting machine, the wire cutting machine has a cutting unit for cutting silicon wafers, a water storage tank located on the top of the cutting unit, and a waste water recovery chamber for reclaiming the waste generated after cutting Waste water; the waste water recovery cavity is connected with the water inlet of the waste water collection system 10 through pipelines, and the water outlet of the waste water collection system 10 is connected with the waste water treatment system 20 (the structural schematic diagram of the waste water treatment system 20 and figure 2 The first waste liquid storage tank 201 of the same) is connected, and then successively connect the filter press device 202, the second waste liquid storage tank 203, the ceramic membrane filter device 204, and the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com